Dangerous waste heat treatment tank type testing furnace device

A hazardous waste and electric furnace technology, which is applied in the direction of furnace control device, electric furnace heating, furnace, etc., can solve the problems that cannot meet the requirements of high temperature treatment of solid waste, cannot collect and process harmful waste gas, and is not suitable for solid waste treatment, so as to save experiment time , fast heating speed, and the effect of realizing zero discharge of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the protection scope of the present invention is not limited to the scope described in the embodiments.

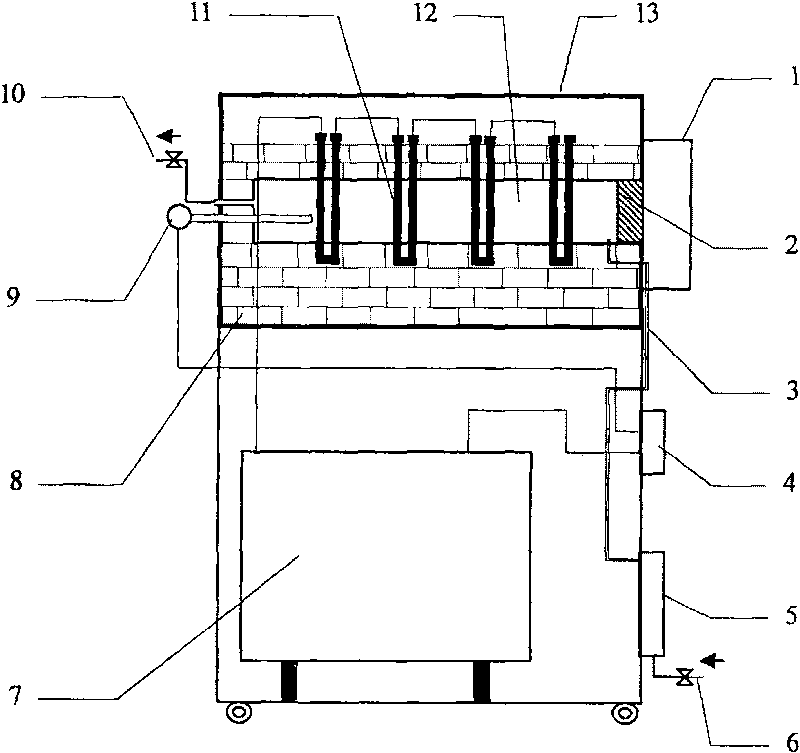

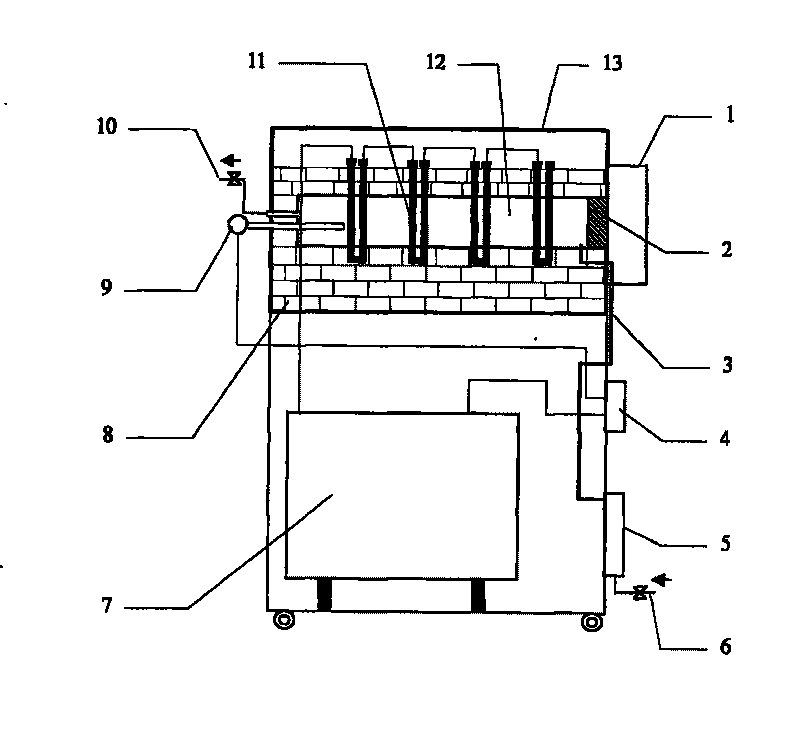

[0027] Such as figure 1 As shown, the hazardous waste heat treatment box-type experimental electric furnace device includes a sealed heating system, a gas circuit system and a temperature control system. The sealed heating system includes a furnace body sealed shell 13, a furnace 12, a silicon molybdenum rod heating system 11, a high temperature resistant furnace lining 8, a furnace door 1 and a fire brick 2; A fire block 2 is set at the furnace door, and the furnace hearth 12 is set in the high-temperature resistant furnace lining 8. Eight silicon-molybdenum rods form a silicon-molybdenum rod heating system 11, and the high-temperature resistant furnace lining 8 is arranged in series on the left and right sides of the furnace 12 through alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com