Reed-based biomass rod utilization production system

A production system and biomass technology, applied in the fields of biofuels, waste fuels, solid fuels, etc., can solve the problems of poor exhaust effect, affecting the quality and efficiency of biomass particle production, and easy loosening of biomass particles. Improve the firmness, the use value is obvious, and the effect of reducing looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

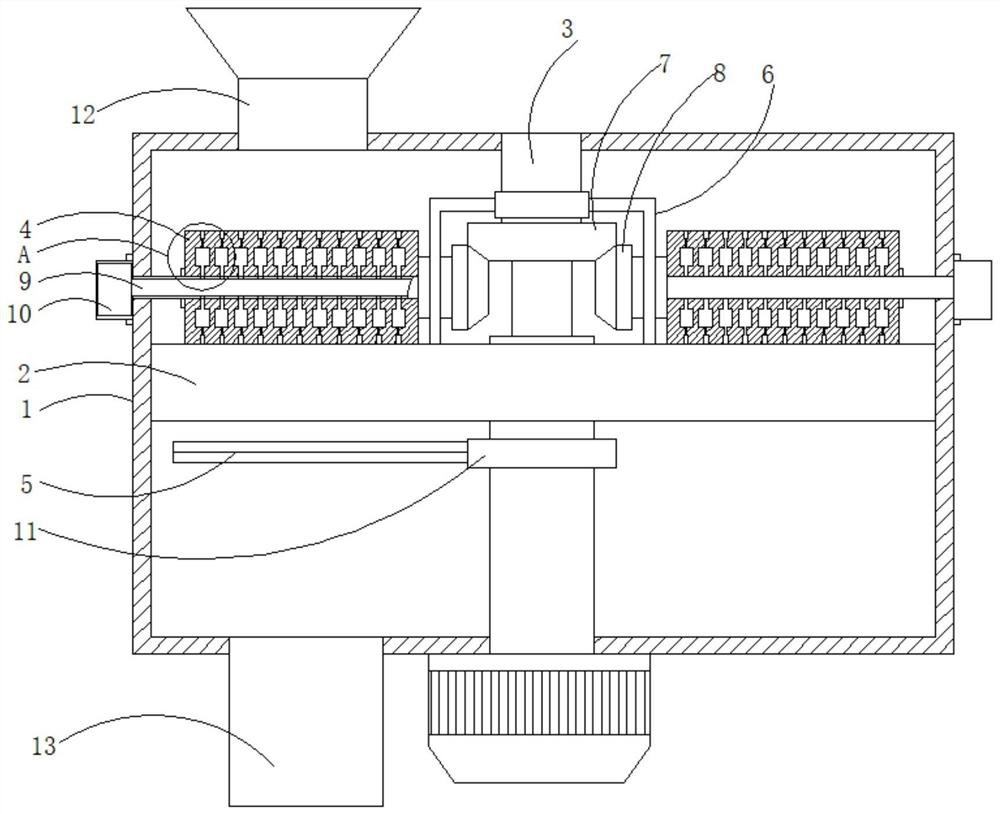

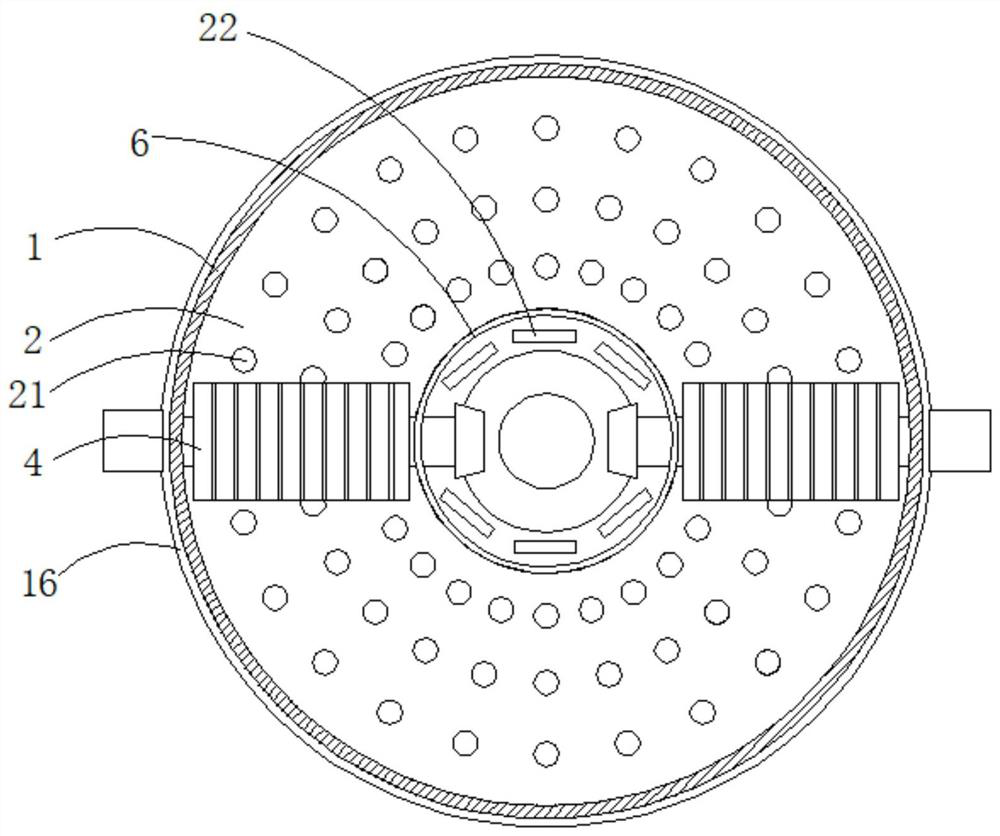

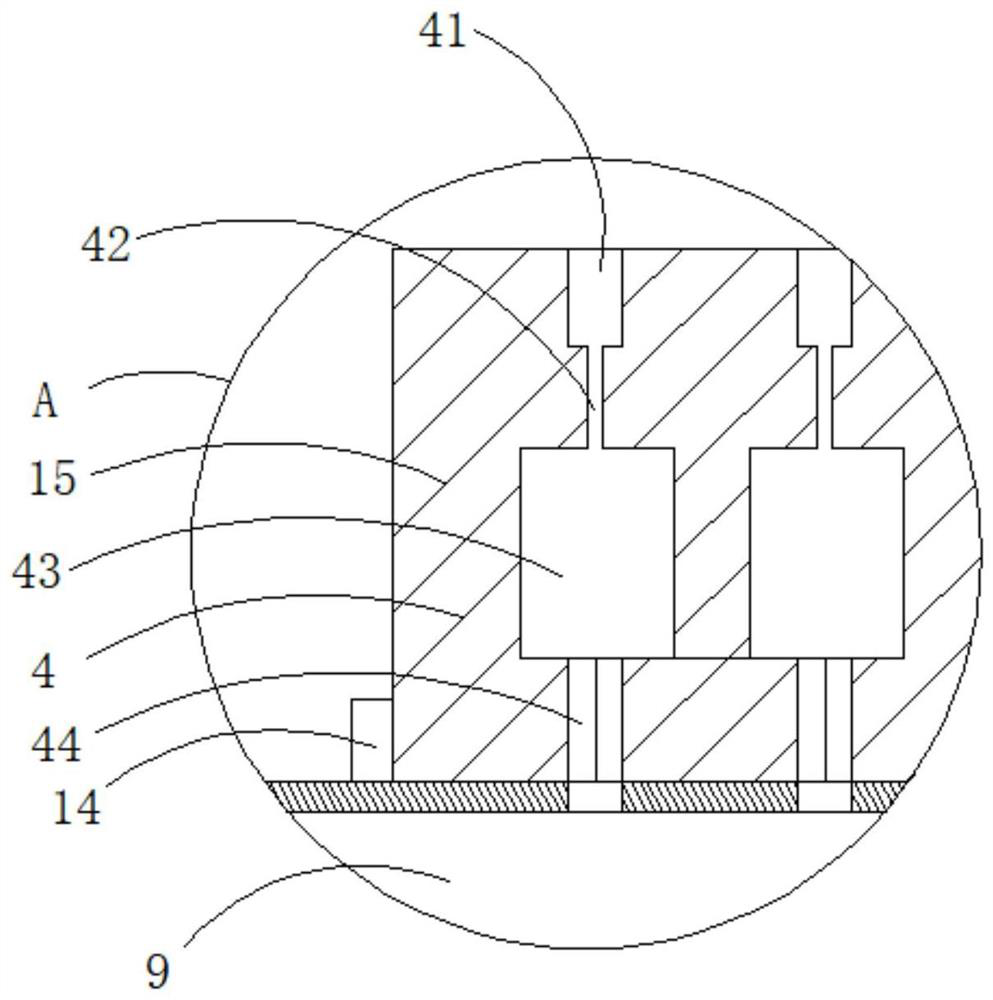

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] The reed-based biomass rod utilization production system includes a chipper, a pulverizer, a drying fan, a dust collector, and a granulation device. The chipper chips the reeds, and then sends the reed pieces into the pulverizer through the screw feeder for crushing to obtain the reed base powder, which is dedusted by the dust collector, and then dried by the drying fan. drying, so that the water content of the reed base powder meets the granulation standard, and the granulation device is used for granulation of the reed base powder to obtain rod-shaped particles of reed base biomass.

[0024] The chipper, pulverizer, drying fan and dust remover in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com