Plastic-coated steel pipe production process

A technology of plastic-coated steel pipe and production process, which is applied in the direction of coating, device for coating liquid on the surface, cleaning of hollow objects, etc. Insufficient force, etc., to avoid the decline of cleaning uniformity, maintain the wiping effect, and reduce the probability of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

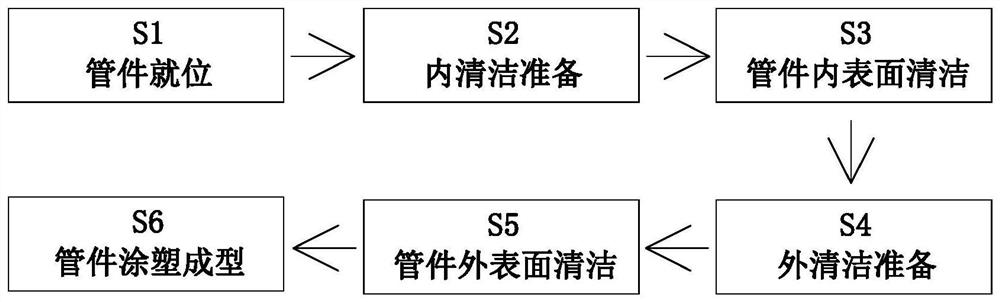

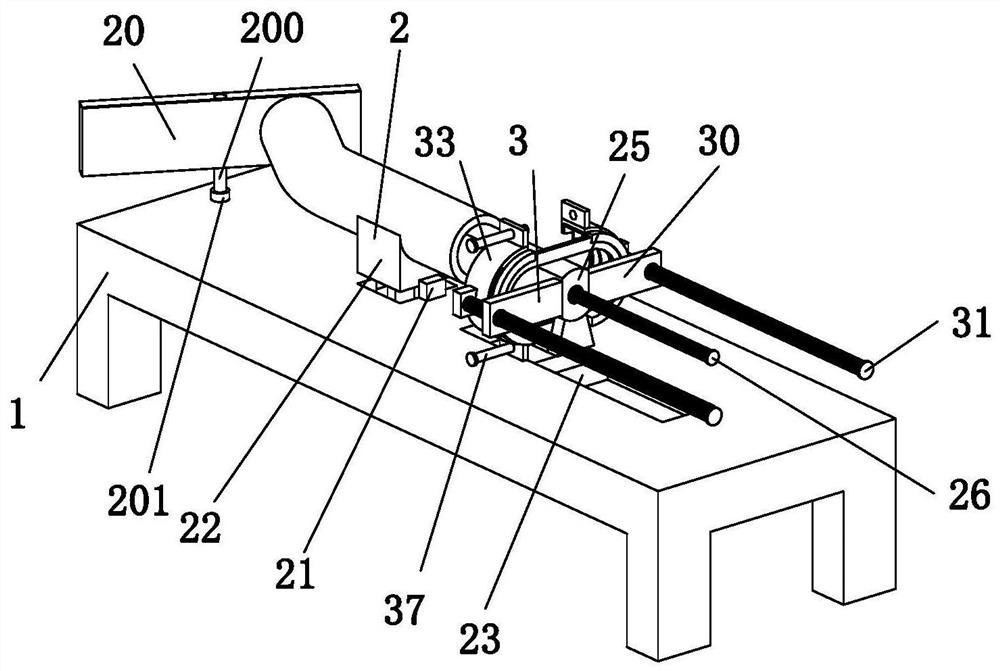

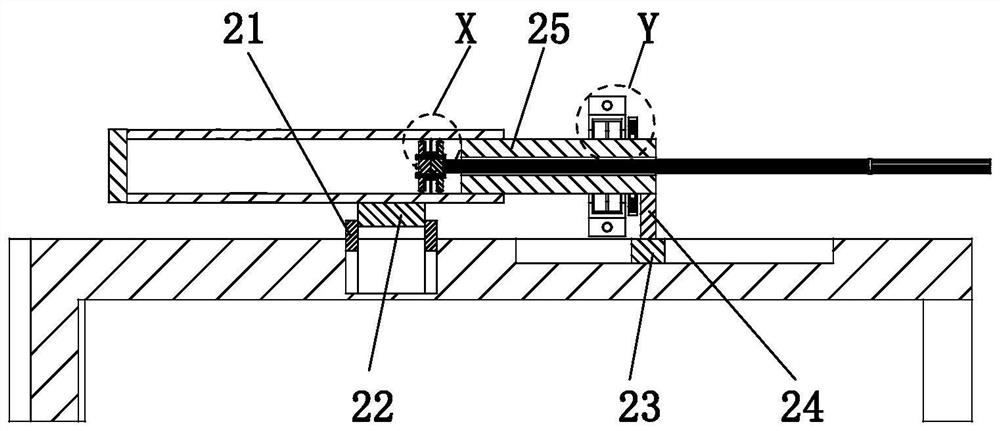

[0040] Such as Figure 1 to Figure 10 A plastic-coated steel pipe production process is shown, which uses a plastic-coated steel pipe production device. The plastic-coated steel pipe production device includes a workbench 1, an inner cleaning mechanism 2, and an outer cleaning unit 3. The specific production process of the tube production is as follows:

[0041] S1. Fitting in place: place the fitting on the middle seat 22 manually and stick the left end to the limit plate 20;

[0042] S2. Internal cleaning preparation: manually push the middle piece 26 to the left, the inner circular plate 27 drives the inner scraper 29 to move synchronously with the middle piece 26, and after the inner circular plate 27 enters the pipe for a certain distance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com