Single-plate electrode electric field driving spraying deposition micro-nano 3D printing method

A flat-plate electrode and spray deposition technology, which is applied in processing and manufacturing, additive processing, liquid material additive processing, etc., can solve the problems of short service life, high nozzle manufacturing cost, and long cycle, so as to expand the application field and function, Solve the effect of low-cost manufacturing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

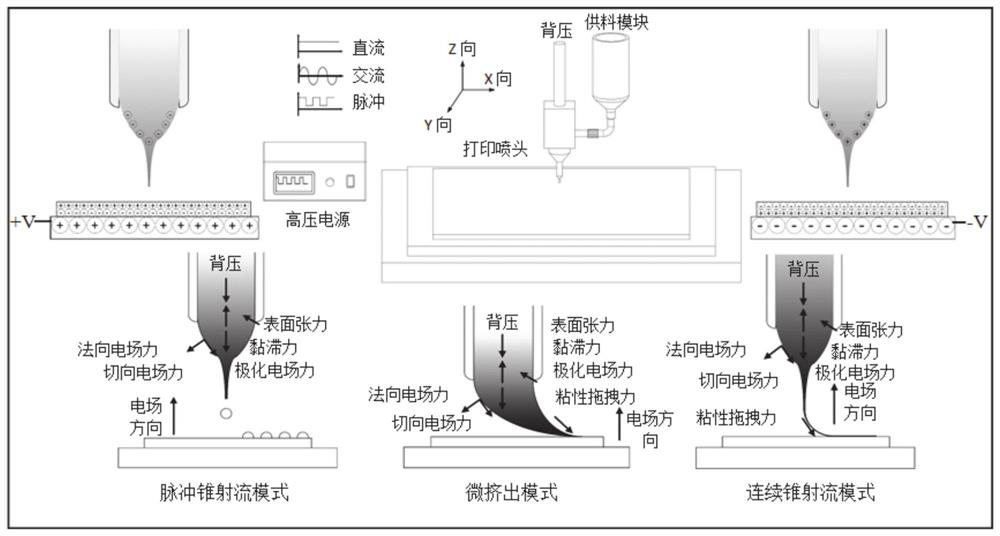

Method used

Image

Examples

Embodiment 1

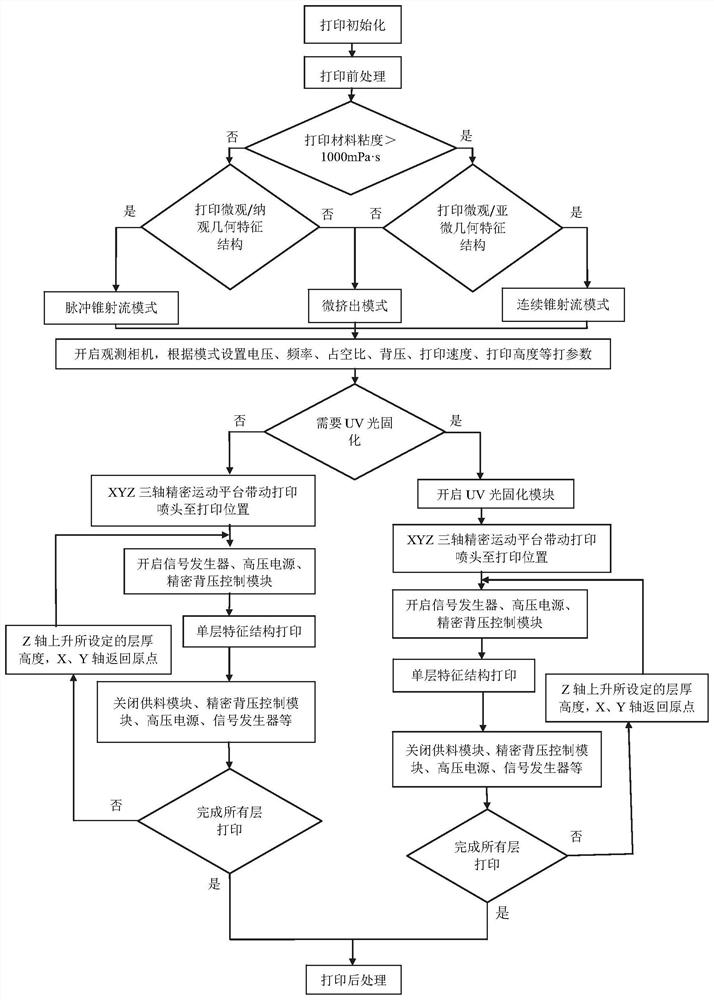

[0092] Such as figure 2 As shown, Embodiment 1 of the present disclosure provides a working method for manufacturing a transparent electrode by a single-plate electrode electric field-driven single-nozzle jet deposition micro-nano 3D printer.

[0093] Among them: the printing material is nano-conductive silver paste (viscosity 35000mPa s, silver content 80%, surface tension 32dynes / cm); the printing nozzle is 30G stainless steel conductive nozzle, the inner diameter is 0.16mm; the printing substrate is 100mm×100mm×2mm Ordinary transparent glass; plate electrode selection 150mm×150mm×3mm copper plate.

[0094] The specific printing process and printing parameters are as follows:

[0095] Step 1: Print initialization.

[0096] Fix the printing substrate on the flat electrode; each motion module is enabled, and the XYZ three-axis precision motion platform moves to the initial printing position.

[0097] Step 2: Pre-printing processing.

[0098] First of all, the material vis...

Embodiment 2

[0107] Embodiment 2 of the present disclosure provides a typical working method for manufacturing flexible hybrid circuits across macro-micro scales by using single-plate electrode electric field-driven spray deposition micro-nano 3D printing technology.

[0108] Among them: the printing materials are successively selected as nano-conductive silver paste (viscosity of 35000mPa s), PDMS (viscosity of 3500mPa s); printing nozzles are selected from glass insulating nozzles (inner diameter of 50 μm), 27G stainless steel conductive nozzles (inner diameter of 200 μm); A 250mm×250mm×3mm copper plate is selected as the plate electrode.

[0109] The specific printing process and printing parameters are as follows:

[0110] Step 1: Print initialization.

[0111] Fix the printing substrate on the flat electrode; each motion module is enabled, the XYZ three-axis precision motion platform moves to the initial printing position, the printing platform is turned on for heating, and the tempe...

Embodiment 3

[0122] In order to achieve high-efficiency and large-area manufacturing of transparent electrodes, Embodiment 3 of the present disclosure provides a working method of a single-plate electrode electric field-driven single-material multi-nozzle jet deposition micro-nano 3D printing device.

[0123] Among them: the printing material is nano-conductive silver paste (viscosity 35000mPa s, silver content 80%, surface tension 32dynes / cm); printing nozzles are 30G stainless steel conductive nozzles (inner diameter is 0.16mm), and printing nozzles are 4 diamond-shaped rows. Cloth; printing substrate selection 300mm × 300mm × 2mm ordinary transparent glass; plate electrode selection 350mm × 350mm × 3mm copper plate.

[0124] The specific printing process and printing parameters are as follows:

[0125] Step 1: Print initialization.

[0126] Fix the printing substrate on the flat electrode, enable each motion module, and move the XYZ three-axis precision motion platform to the initial p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com