Preparation method of solvent-free automotive interior synthetic leather

An automobile interior, solvent-free technology, applied in the field of synthetic leather, can solve the problems of inability to meet the requirements of automobile interior materials, poor bonding between materials and isocyanates, impossible to meet environmental protection and safety requirements, etc., so as to avoid smoke suffocation and death. The effect of reducing smoke density and ensuring flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

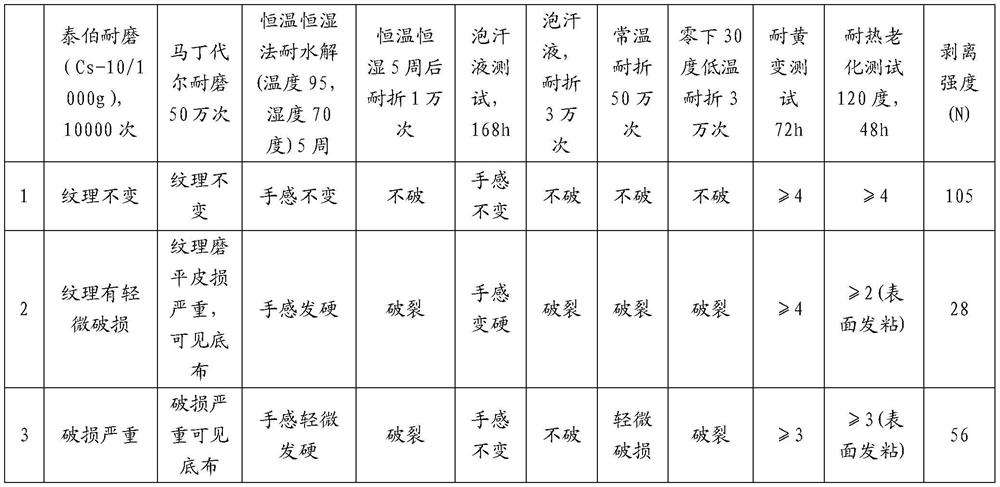

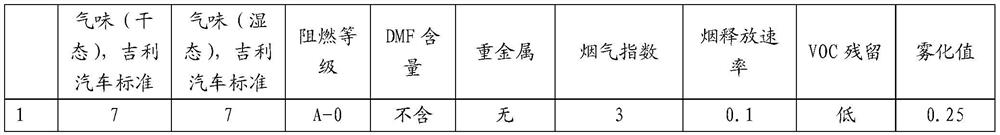

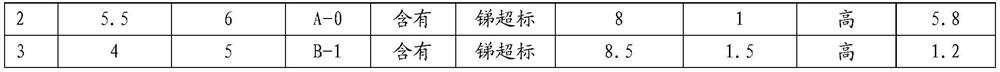

Examples

Embodiment 1

[0035] A method for preparing a solvent-free automotive interior synthetic leather, the solvent-free automotive interior synthetic leather comprises a water-based surface layer and a solvent-free bottom layer; the solvent-free bottom layer is formed by mixing components A and B.

[0036] Described preparation method comprises the steps:

[0037] Step 1: Put the prepared water-based surface layer mixture on the machine for production, the interval between the first coating is 10 seconds for scraping, the oven temperature is 110 degrees, the drying time is 1.5 minutes, the interval between the second coating is 11 seconds, and the temperature is 120 degrees , the drying time is 2 minutes; get a water-based surface layer;

[0038] The preparation method of described aqueous surface layer mixture comprises:

[0039] Step 11: Take 100g of water-based resin and stir at a speed of 300rpm, then add 0.2g of defoamer, 5g of colorant, 2g of leveling agent, and 2.5g of hand feeling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com