Polyethylene plastic pipe manufacturing and processing technology

A polyethylene plastic pipe and processing technology technology, which is applied in the direction of manufacturing tools, metal processing equipment, tubular articles, etc., can solve the problem of taking a long time to work, increasing the labor intensity of workers, and reducing the production efficiency of polyethylene plastic pipes. problem, to achieve the effect of improving efficiency and increasing the support distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention , and are not intended to limit the present invention.

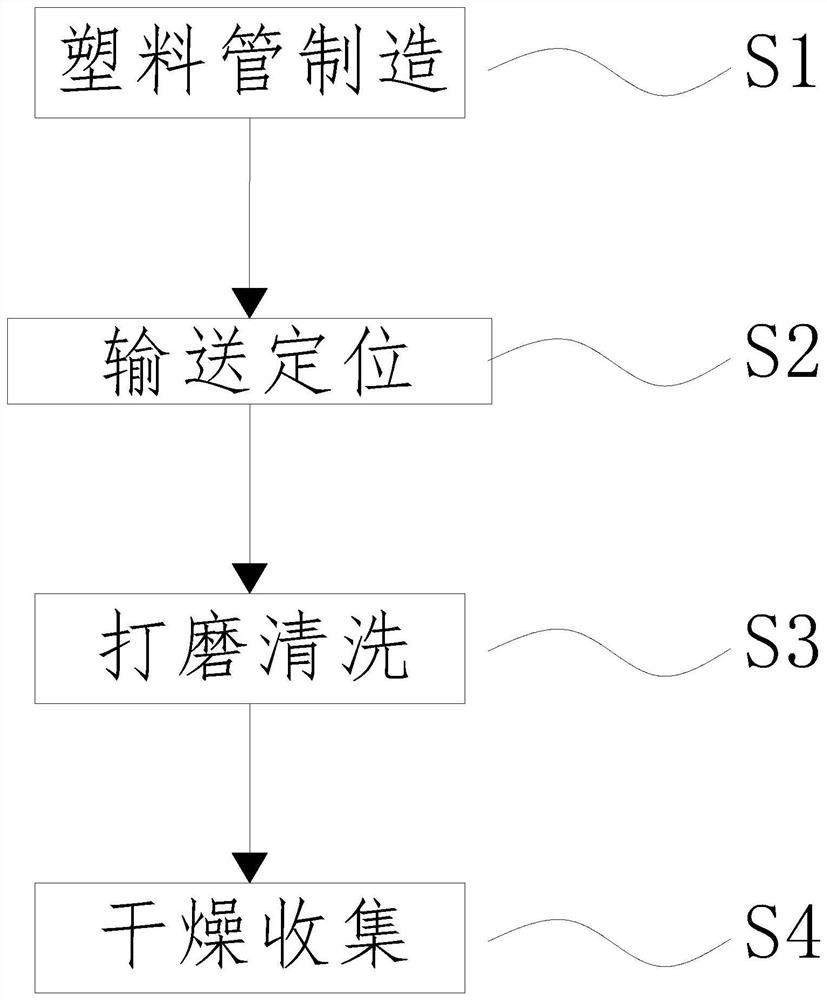

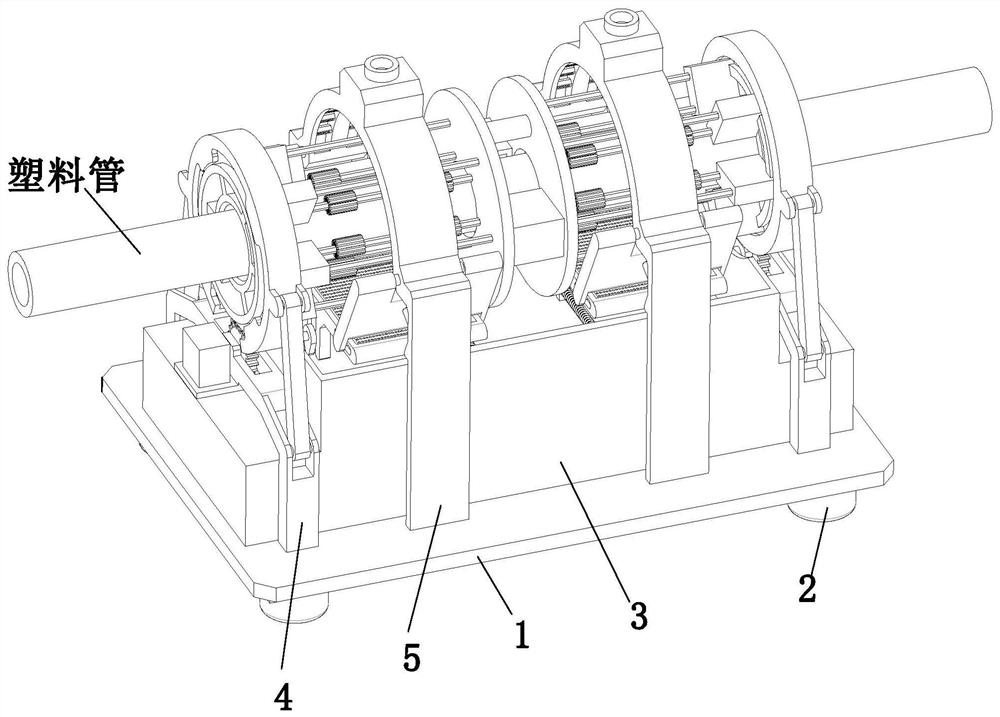

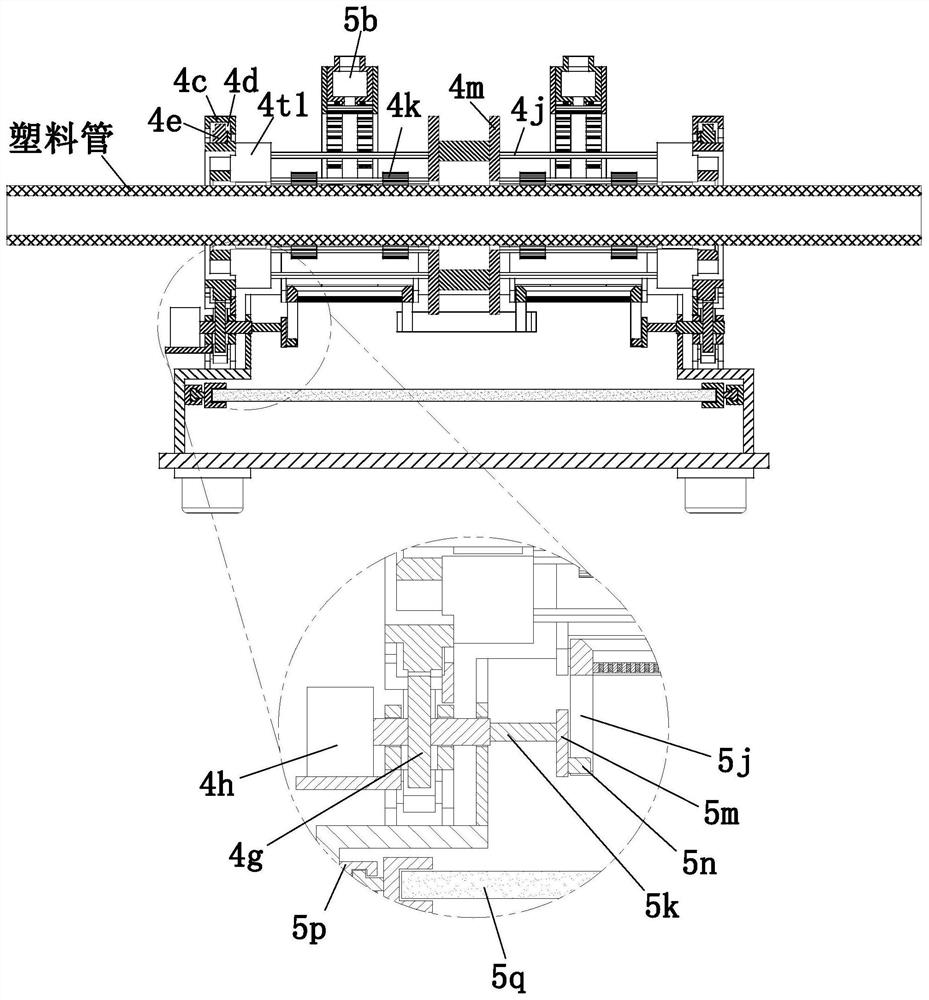

[0033] Refer to 1-7, a polyethylene plastic pipe manufacturing process, which uses a polyethylene plastic pipe manufacturing and processing device, the polyethylene plastic pipe manufacturing and processing device includes a mounting base plate 1, a support column 2, a liquid storage tank 3. The polishing mechanism 4 and the cleaning mechanism 5, when using the above-mentioned polyethylene plastic pipe manufacturing and processing device to manufacture and process polyethylene plastic pipes, the specific process is as follows:

[0034] S1. Manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com