Preparation method of gap-variable adsorption material with porous ceramic as matrix

A technology of porous ceramics and adsorption materials, which is applied in the field of variable-gap adsorption material preparation, can solve the problems of reduced flushing force and great difficulty in cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] see figure 1 A method for preparing a variable-gap adsorption material based on porous ceramics, comprising the following steps:

[0045] S1. Prepare a porous ceramic material with large pores and open pores, clean it with deionized water, and dry it for later use;

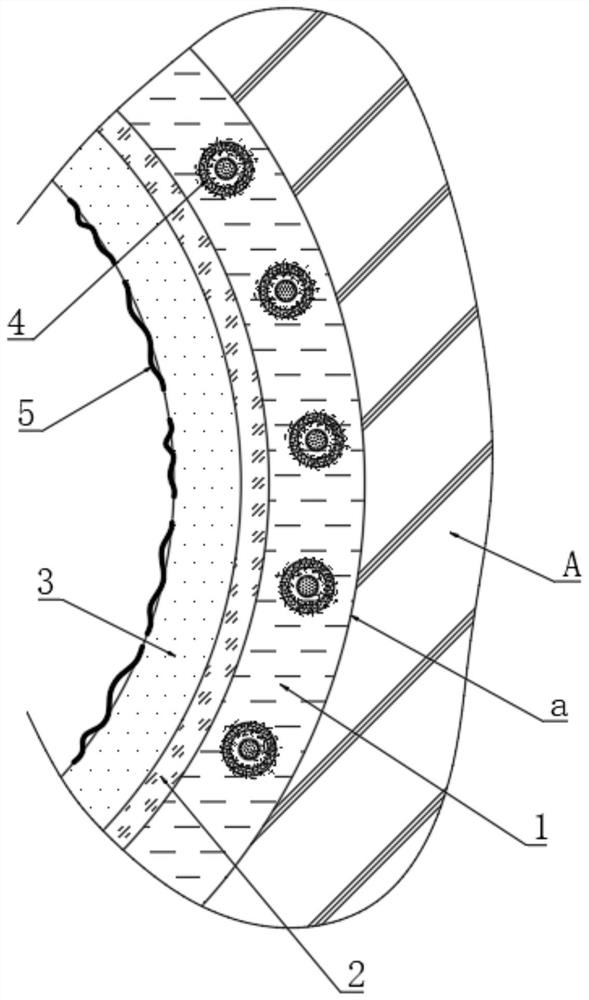

[0046] S2. Immerse the porous ceramic material in a container filled with thermoplastic slurry M in a low-temperature molten state, and slowly extract air to form a vacuum, so that the slurry M is fully filled in the pores of the porous ceramic material, and the porous ceramic material is taken out. The airflow dredges the porous ceramics, removes the excess slurry M inside the ceramic pores, dredges the pores, and forms a phase change layer 1 on the surface of the ceramics and the inner wall of the pores after cooling to obtain a semi-finished product 1, such as figure 1 As shown, wherein A represents the porous ceramic material, and a represents the pore inner wall of the porous ceramic material;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com