Preparation method for continuous flow synthesis of clonazepam

A technology for clonazepam and flow synthesis is applied in the field of preparation of continuous flow synthesis of clonazepam, can solve problems such as unfavorable production capacity, and achieve the effects of improving purity, safe and efficient mass transfer and heat transfer, and no amplification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

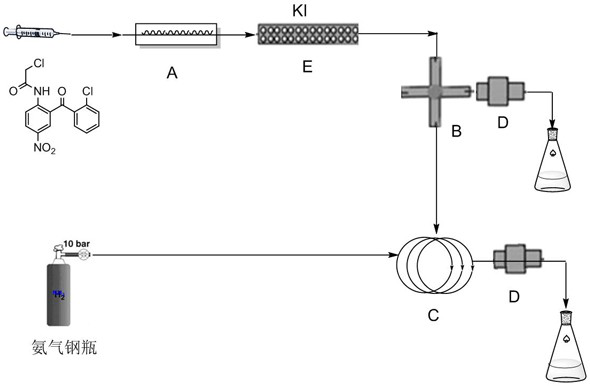

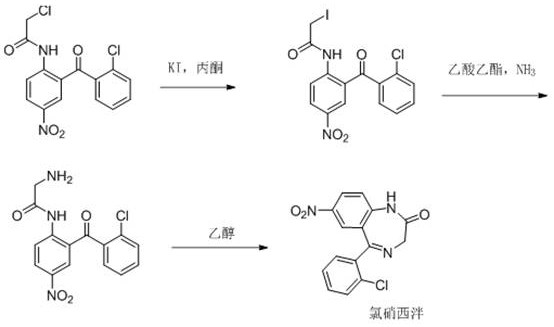

[0040] The preparation method of clonazepam comprises the following steps:

[0041] (1) Pump the acetone solution of 2 mol / L starting material chloride into the heat exchanger, stay for 0.5s, then flow into the fixed bed of potassium iodide, and react to obtain the intermediate iodide;

[0042] (2) The iodide flows into the tubular reactor again, the flow rate is 30ml / min, and the residence time is maintained at 20s. At the same time, ammonia gas is introduced into the reactor, and the internal pressure of the reactor is controlled to be 0.5Mpa. The reaction liquid is continuously collected, and the organic phase Concentrate under reduced pressure, reclaim acetone, obtain crude product clonazepam;

[0043] (3) Further recrystallization using methanol to obtain clonazepam.

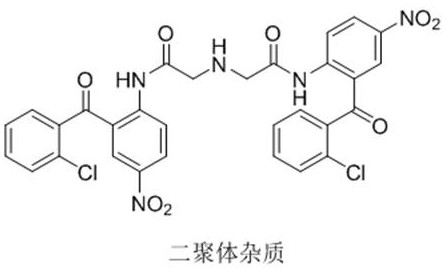

[0044] After testing, the yield of the obtained product was 78%, HPLC detection showed that the purity of the product was 99.8%, and the content of impurity dimer was about 0.074%.

Embodiment 2

[0046] The preparation method of clonazepam comprises the following steps:

[0047] (1) Pump the acetone solution of 2 mol / L starting material chloride into the heat exchanger, stay for 0.5s, then flow into the fixed bed of potassium iodide, and react to obtain the intermediate iodide;

[0048] (2) The iodide flows into the tubular reactor again, the flow rate is 30ml / min, and the residence time is maintained at 20s. At the same time, ammonia gas is introduced into the reactor to control the internal pressure of the reactor to 0.1Mpa, and the reaction liquid is collected continuously. The organic phase Concentrate under reduced pressure, reclaim acetone, obtain crude product clonazepam;

[0049] (3) Further recrystallization with ethanol to obtain clonazepam.

[0050] After testing, the yield of the obtained product was 85%, HPLC detection showed that the purity of the product was 92%, and the content of impurity dimers was about 0.092%.

Embodiment 3

[0052] The preparation method of clonazepam comprises the following steps:

[0053] (1) Pump the acetone solution of 2 mol / L starting material chloride into the heat exchanger, stay for 0.5s, then flow into the fixed bed of potassium iodide, and react to obtain the intermediate iodide;

[0054] (2) The iodide flows into the tubular reactor again, the flow rate is 40ml / min, and the residence time of 20s is maintained. At the same time, ammonia gas is introduced into the reactor, and the internal pressure of the reactor is controlled to 1Mpa. The reaction liquid is continuously collected, and the organic phase is subtracted. Concentrate under pressure, reclaim acetone, obtain crude product clonazepam;

[0055] (3) Further recrystallization with ethanol to obtain clonazepam.

[0056] After testing, the yield of the product obtained was 79%, HPLC detection showed that the purity of the product was 99%, and the content of impurity dimers was about 0.085%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com