A horizontal continuous feeding electric arc furnace scrap distributing device and distributing method thereof

A technology of distributing device and electric arc furnace, which is applied to electric furnaces, furnaces, furnace types, etc., can solve the problems of melting and sticking of light scrap steel on the conveying roller table, etc., to ensure normal use, increase preheating temperature, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

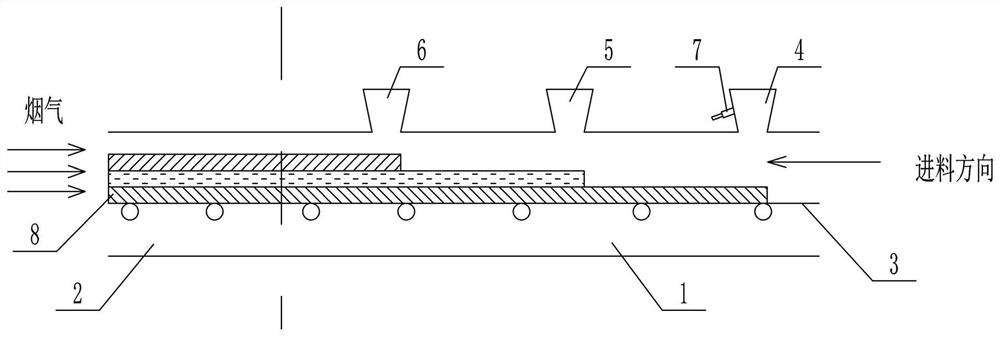

[0034] Such as figure 1 As shown, this embodiment provides a horizontal continuous feeding electric arc furnace scrap distributing device, including a feeding channel 1, a preheating channel 2 for preheating with flue gas, and a conveying roller table running through the feeding channel 1 and the preheating channel 2 3. It also includes a number of feeding bins arranged at intervals. Several feeding bins are located above the feeding channel 1, and the bottom is equipped with a blanking port; the volume types of scrap steel stored in several feeding bins are different, and along the feeding direction Decreases in turn, and a heating device for heating scrap steel is also provided in a part of the feeding bin at the starting end of the feeding direction.

[0035] When feeding, first turn on the heating device to preheat the scrap steel. After reaching the preheating temperature, the feeding bin at the end opens the discharge port, so that the scrap steel falls on the conveying ...

Embodiment 2

[0045] This embodiment provides a method for distributing scrap steel in an electric arc furnace with horizontal continuous feeding, which includes the following steps:

[0046] 1) Turn on the heating spray gun 7 to heat the heavy-duty steel scrap in the first feeding bin 4, and when the heating reaches the set temperature, open the blanking port so that the heavy-duty steel scrap falls on the conveying roller table 3, and continue feeding to form a heavy-duty steel scrap layer;

[0047] 2) When the heavy steel scrap is transported to the bottom of the second feeding bin 5, the discharge opening on the second feeding bin 5 is opened, so that the mixed steel scrap falls on the top of the heavy steel scrap layer 8, and the mixed steel scrap layer is formed by continuous feeding;

[0048] 3) When the heavy steel scrap and mixed steel scrap are transported to the bottom of the third feeding bin 6, the discharge opening on the third feeding bin 6 is opened, so that the light materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com