Particulate matter trapping and regenerating system applying turbulent agglomeration as pretreatment and control method

A regeneration system and particle technology, applied in the electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, exhaust treatment, etc., can solve problems such as deterioration of engine power and fuel economy, and increase of engine back pressure , to achieve the effect of increasing the probability of collision, increasing the particle size, and promoting the regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with accompanying drawings and embodiments, but those skilled in the art should know that the following embodiments are not the only limitation to the technical solution of the present invention, and any work done under the spirit of the technical solution of the present invention Equivalent transformation or modification shall be considered as belonging to the protection scope of the present invention.

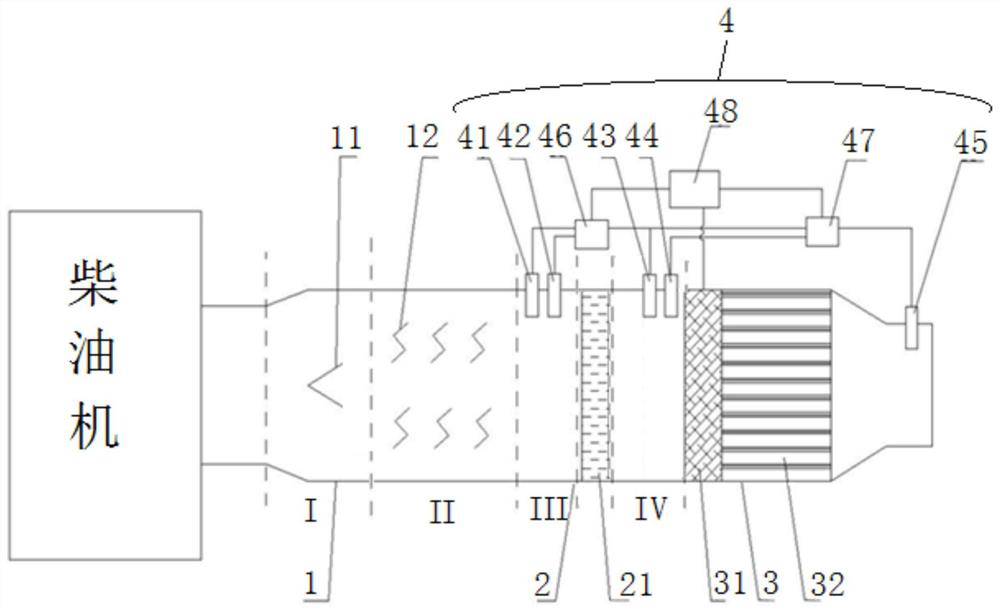

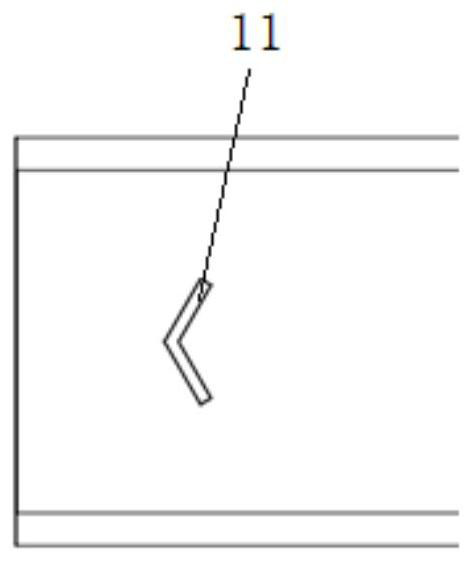

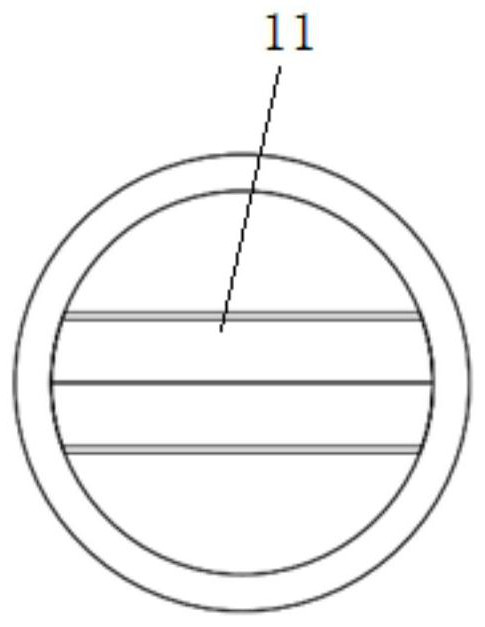

[0042] Such as figure 1 As shown, the present invention provides a diesel engine exhaust particulate matter capture and regeneration system, which uses turbulent flow aggregation as a pretreatment method, and generally includes a turbulent flow aggregation unit 1, a differential pressure generation unit 2, a regeneration filter unit 3 and a regeneration control unit. Unit 4 several parts. The turbulence coalescing unit 1 , the differential pressure generating unit 2 and the regenerative filter unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com