Buffer element and power head buffer device with same

A technology of buffer element and impact head, applied in the direction of spring, shock absorber, spring/shock absorber, etc., can solve the problems of the guide rod cannot be ejected, the buffer effect is poor, and the dynamic sealing performance is poor, so as to reduce the processing difficulty and processing. Cost, Guaranteed Cushioning and Shock Absorption, Guaranteed Cushioning and Shock Absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

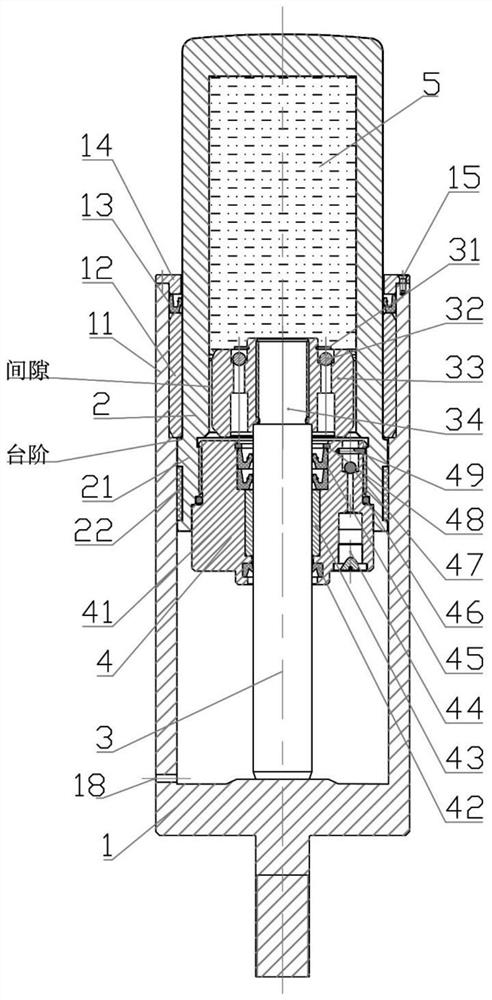

[0057] refer to figure 1 As shown, a buffer element includes an outer cylinder assembly 1, an inner cylinder assembly 2 and a piston rod assembly 3. The improvement is that the outer cylinder assembly 1 includes an inner The outer cylinder body 11 of the cylinder body assembly 2 and the piston rod assembly 3, the outer cylinder body 11 is in sliding and sealing connection with the inner cylinder body 21 of the inner cylinder body assembly 2, and the end of the inner cylinder body 21 is connected to the end cover of the inner cylinder body Assemblies 4, the inner cylinder end cover assembly 4 is in sliding sealing connection with the piston rod 34 of the piston rod assembly 3, the piston rod 34 is connected with the impact head 33, the gap between the impact head 33 and the inner cylinder body 21 Cooperate, the inner cavity of the inner cylinder 21 is injected with elastic cement 5; the end of the inner cylinder 21 exposed to the outer cylinder 11 slides downward in the outer c...

Embodiment 2

[0063] On the basis of embodiment 1, with reference to figure 1 As shown, the outer cylinder assembly 1 also includes a copper sleeve I12, a skeleton oil seal I13 and an outer cylinder end cover 14. Sliding fit, the skeleton oil seal I13 is arranged on the upper end of the copper sleeve I12, and the outer cylinder body end cover 14 is arranged at the port of the outer cylinder body 11 and is clearance-fitted with the inner cylinder body 21.

[0064] Further, the end cover 14 of the outer cylinder body is fixed on the port of the outer cylinder body 11 by screws 15 .

[0065] Further, the copper sleeve I12 is a self-lubricating copper sleeve, and the surface of the inner hole is embedded with graphite material.

[0066] In this embodiment: the copper sleeve I12 ensures that the inner cylinder body 21 moves along the axial direction in the outer cylinder body 11; the skeleton oil seal I13 seals the inner cylinder body 21, thereby preventing foreign silt and other impurities fro...

Embodiment 3

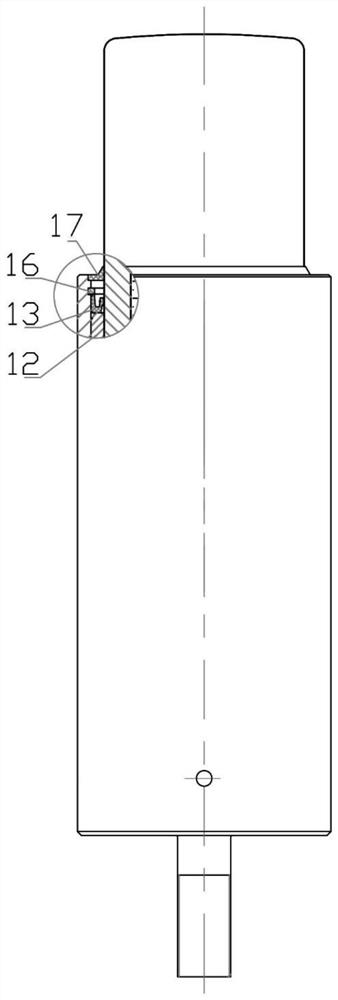

[0068] On the basis of embodiment 1, with reference to figure 2 As shown, the outer cylinder body assembly 1 also includes a copper sleeve I12, a skeleton oil seal I13, a retaining ring I16 for holes and a dust-proof strip 17, and the copper sleeve I12 is arranged on the steps of the inner wall of the outer cylinder body 11 and is connected with the The inner cylinder body 21 is slidably fitted, the skeleton oil seal I13 is arranged on the upper end of the copper sleeve I12, the hole retaining ring I16 is arranged on the upper end of the skeleton oil seal I13, and the dust-proof strip 17 is bonded to the port of the outer cylinder body 11.

[0069] Further, a groove is provided at the port of the outer cylinder body 11, and the dust-proof strip 17 is bonded in the groove.

[0070] Further, the copper sleeve I12 is a self-lubricating copper sleeve, and the surface of the inner hole is embedded with graphite material.

[0071] In this embodiment: the copper sleeve I12 ensures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com