High-temperature baking cooling device

A cooling device and high-temperature baking technology, which is applied to household refrigeration devices, heating devices, drying, etc., can solve the problems of low cooling efficiency, long time consumption, and high energy consumption, so as to speed up the processing progress, shorten the processing cycle, and improve the baking efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

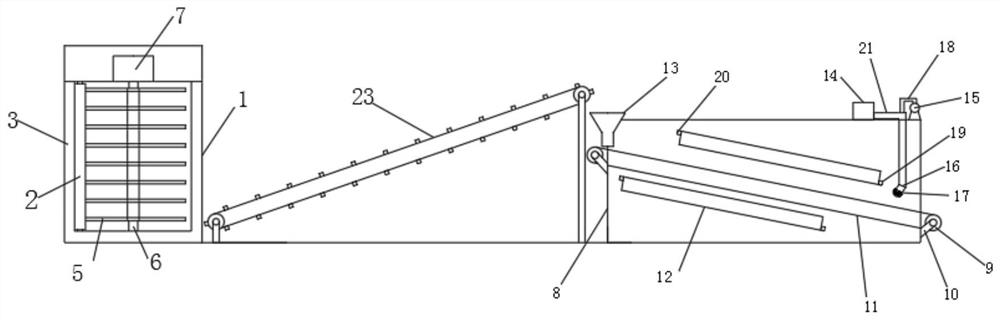

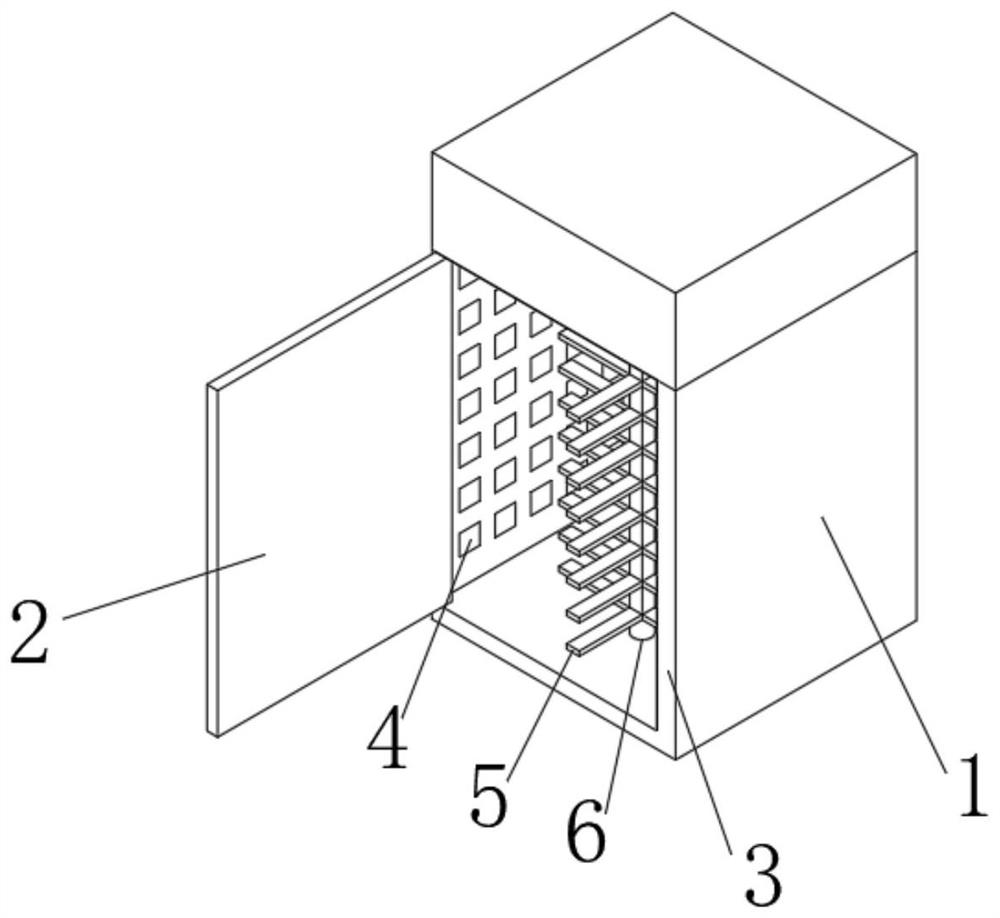

[0023] A high-temperature baking cooling device, in order to solve the traditional baking device low baking efficiency, long time-consuming, energy-consuming, not energy-saving enough, and the baking effect is not ideal, which seriously affects the processing progress of construction spoils, the existing building waste The soil treatment devices all pile up the construction spoil after high-temperature baking on the open space for natural cooling, which greatly prolongs the cycle of construction spoil treatment, the cooling efficiency is low, and the problem is greatly affected by the environment. As a preferred embodiment, as figure 1 , figure 2 and image 3 As shown, it includes a high-temperature baking device 1 and a cooling device 8. A motor 7 is installed inside the high-temperature baking device 1. A rotating shaft 6 is provided at the bottom of the motor 7. The rotating shaft 6 is connected to the output shaft of the motor 7. The surface of the rotating shaft 6 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com