Nuclear power site confined space gas detection method and system

A technology for confined space and gas detection, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to divide alarm levels according to specific situations, inaccurate gas detection data, and unfavorable real-time monitoring, etc., to achieve timely and efficient alarms , good safety, labor cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

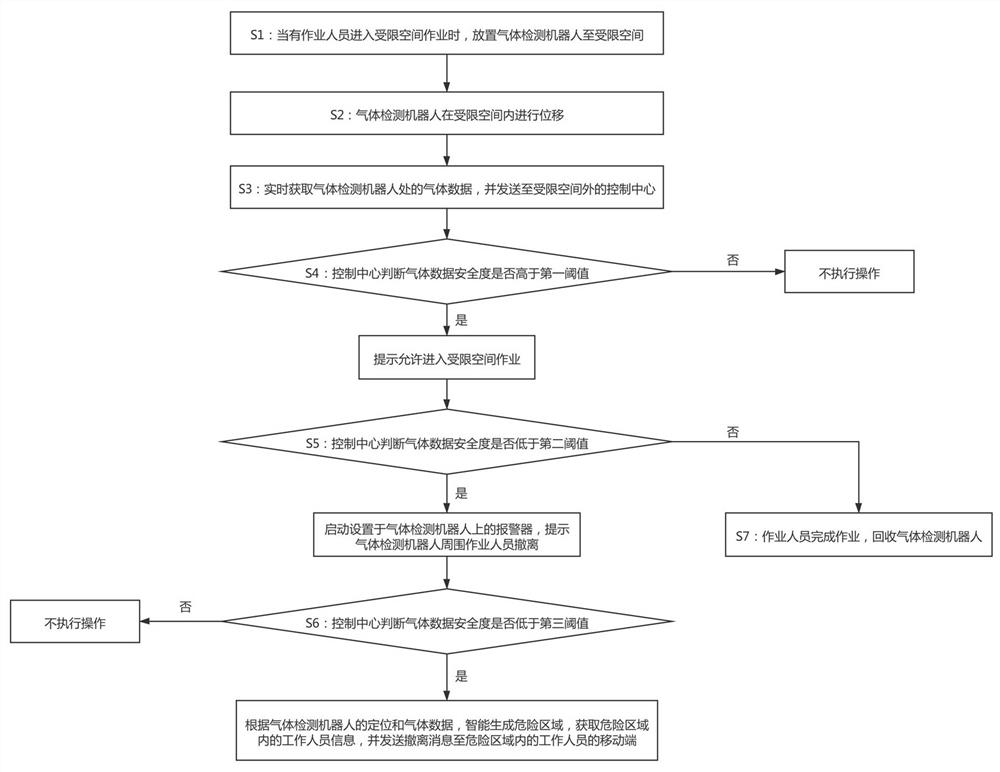

[0050] Embodiment one: if figure 1 As shown, it is only one of the embodiments of the present invention, a method for detecting gas in a confined space of a nuclear power site, comprising the following steps:

[0051] S1: When an operator enters the confined space to work, place the gas detection robot in the confined space;

[0052] When an operator needs to enter the restricted space to work, before the operator enters the restricted space, place the gas detection robot in the restricted space, and let the gas detection robot perform preliminary detection, mainly to detect whether the air in the restricted space is qualified, Avoid danger when workers enter confined spaces.

[0053] A gas detection robot is a machine with a displacement function and a gas detection instrument.

[0054]Of course, before step S1 is executed, the debugging of the gas detection robot is mainly to debug the gas detector and the displacement function of the robot, so as to ensure the accuracy of...

Embodiment 2

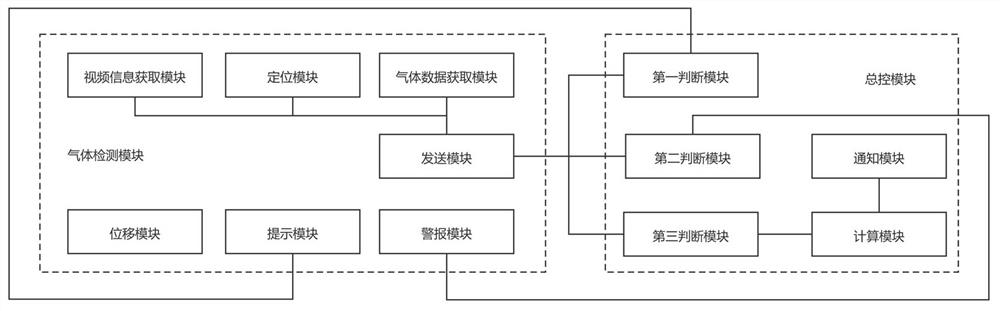

[0080] Embodiment two: if figure 2 As shown, it is only one of the embodiments of the present invention, and the present invention also provides a gas detection system in a confined space at a nuclear power site, which includes:

[0081] Gas detection module;

[0082] displacement module;

[0083] Gas data acquisition module;

[0084] sending module;

[0085] Master control module;

[0086] The first judgment module;

[0087] Prompt module;

[0088] The second judgment module;

[0089] Alarm module;

[0090] The third judgment module;

[0091] computing module;

[0092] notification module;

[0093] When an operator enters the restricted space to work, place the gas detection module in the restricted space, drive the gas detection module to move in the restricted space through the displacement module, and obtain the gas data at the gas detection module in real time through the gas data acquisition module. And send it to the master control module outside the restric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com