Method for researching influence of balance hole diameter on working state of centrifugal pump

A working state, centrifugal pump technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve centrifugal pump impeller disk friction loss, clearance leakage and axial force influence, complex flow and imperfection And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

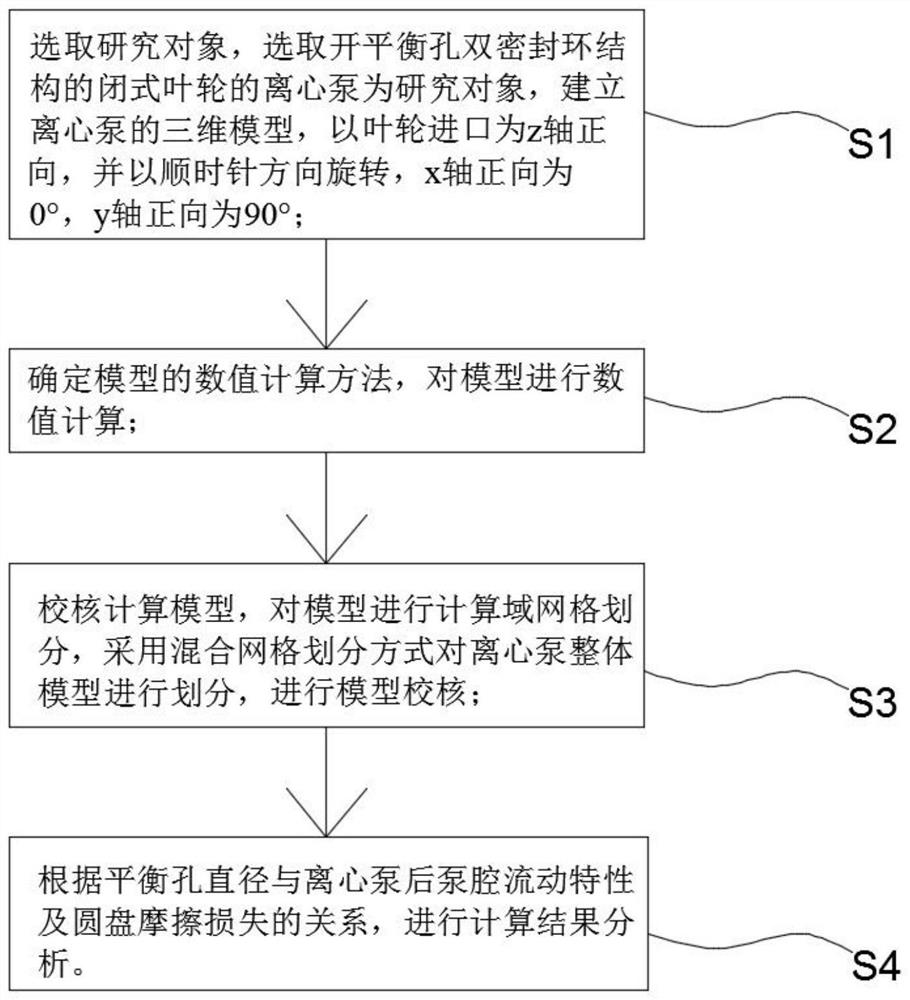

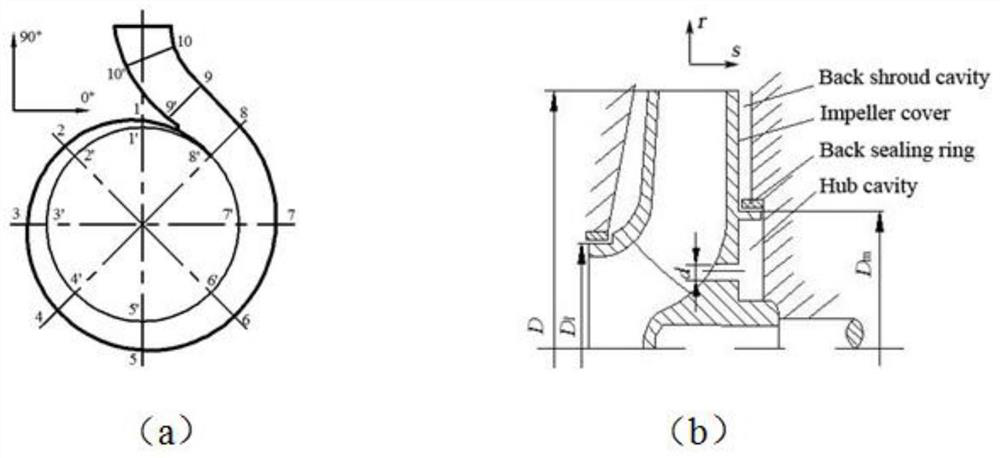

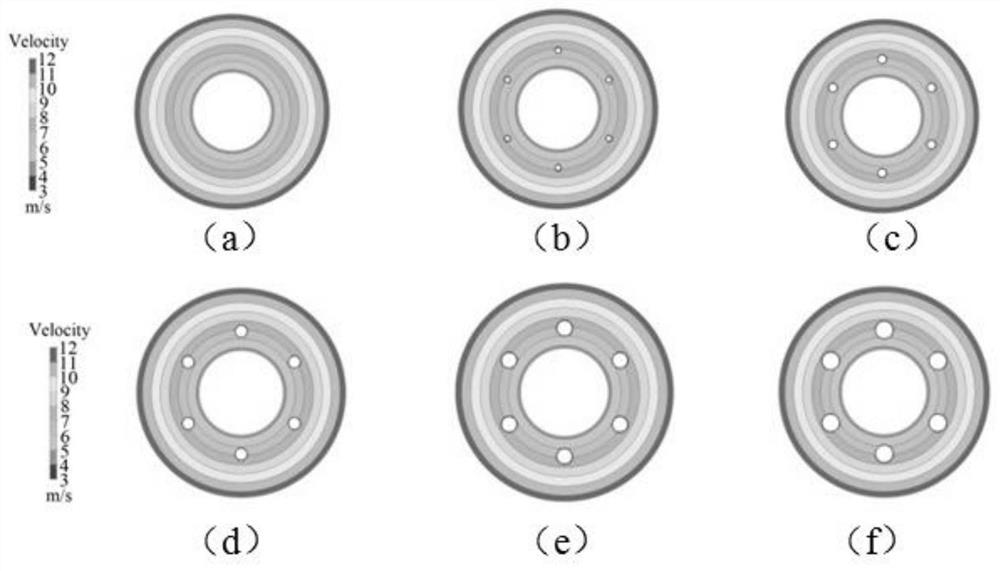

[0048] Embodiment 1: with reference to attached Figure 1-13 A method for studying the effect of the balance hole diameter on the working state of a centrifugal pump is shown, including the steps

[0049] S1. Select the research object. In this research method, the closed impeller centrifugal pump with double seal ring structure with open balance hole is selected as the research object, and it is modeled in a three-dimensional environment. The main design parameters are shown in Table 1:

[0050] Table 1: Design parameters of single-stage single-suction centrifugal pump

[0051]

[0052] Since the centrifugal pump is mainly composed of a volute and an impeller, in the numerical calculation, it is defined in a three-dimensional coordinate system, the spatial position of the impeller is fixed in the pump body, and the axial width of the pump cavity remains unchanged, and the model is established; and in the model establishment Finally, it is stipulated that the impeller inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com