Method for predicting strength of composite material laminated plate containing hole-making layering damage

A composite material layer and composite material technology, applied in the field of composite material detection, can solve problems such as deviation of simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

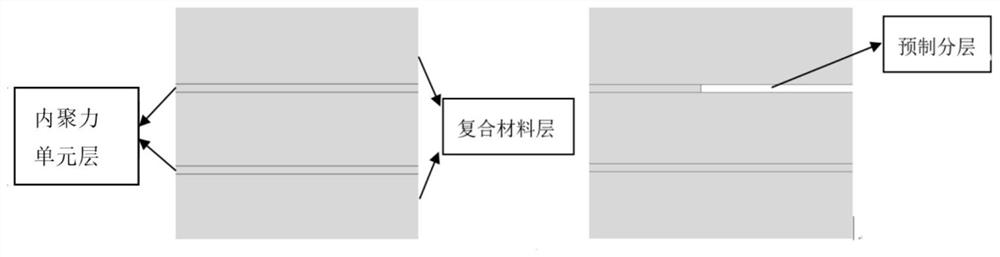

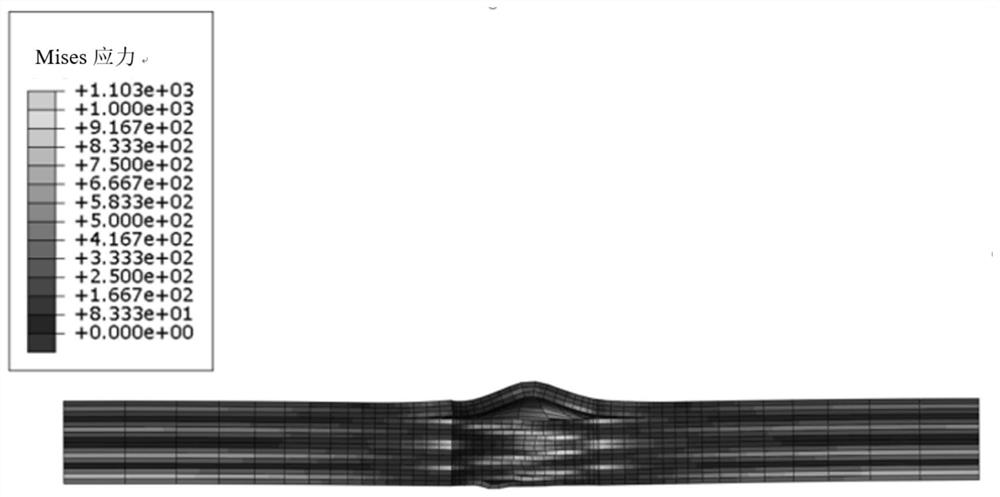

[0073]Step 1. According to the composite material constitutive model in the specific embodiment, this example utilizes the VUMAT user-defined subroutine interface in the ABAQUS software to define the constitutive model of the intralayer unit of the composite material and the constitutive model of the interlayer cohesive force unit, And establish the corresponding two material properties in the software, and fill them in order according to the actual material mechanical performance parameters. The laminated board in this example is T700 carbon fiber reinforced epoxy resin composite material, and its specific mechanical property parameters are shown in Table 2.

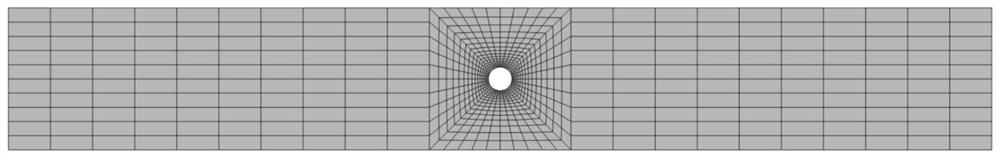

[0074] Step 2. Establish the geometric model of the laminated board according to the example that needs to be simulated and analyzed. This example model uses a perforated laminated board with a size of 300mm×36mm×3mm. The diameter of the hole is 6mm, and the thickness of the single layer is 0.125mm.

[0075] Table 2 Mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com