A kind of transparent conductive film and preparation method thereof

A technology of transparent conductive film and conductive layer, which is applied to equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., which can solve uneven stress distribution and cracking of conductive oxide layers , warping and other issues, to achieve good performance, improve stability, not easy to crack or warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

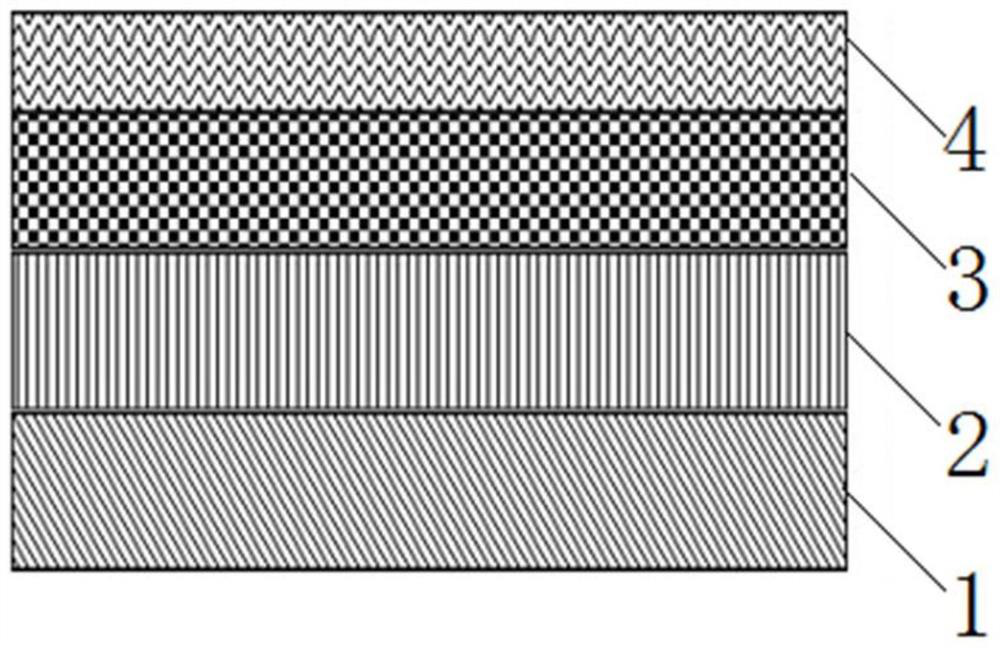

[0044] The present invention also provides a method for preparing a transparent conductive film, comprising:

[0045] Prepare the first conductive layer on the surface of the transparent substrate:

[0046] A layer of conductive oxide is deposited on the surface of the transparent substrate, and then annealed to obtain a first conductive layer, wherein the annealing temperature is 120-170°C, and the annealing time is 20-40min;

[0047] Prepare a second conductive layer on the surface of the first conductive layer:

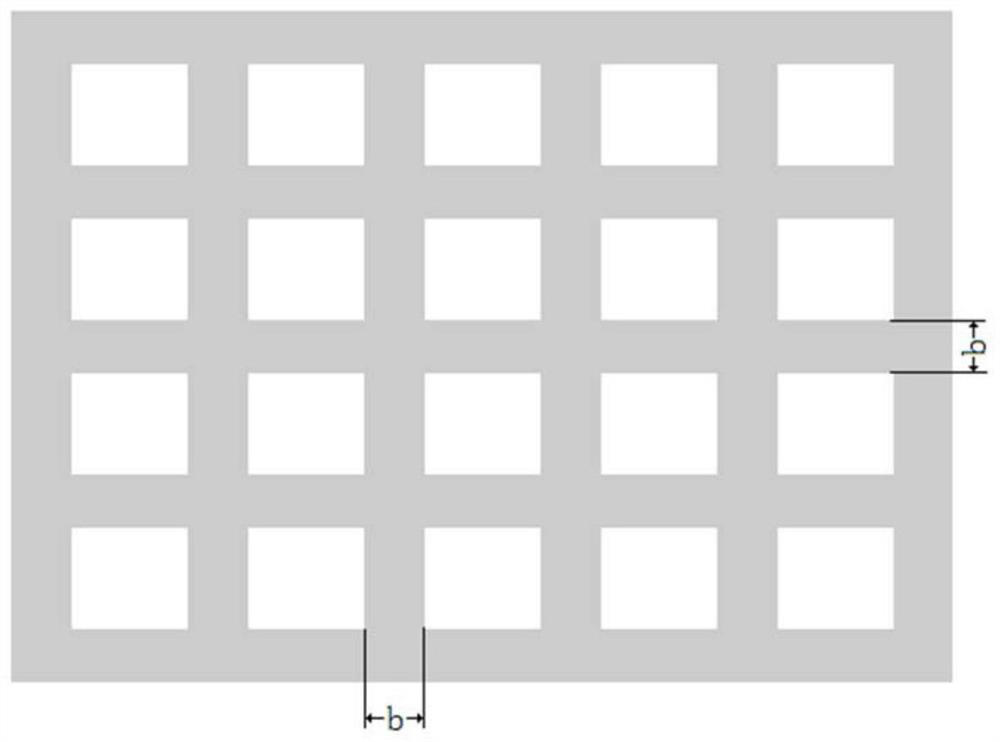

[0048] coating, depositing or printing a conductive material on the surface of the first conductive layer to form a second conductive layer containing a pattern;

[0049] Prepare a third conductive layer on the surface of the second conductive layer:

[0050] A layer of conductive oxide is deposited on the surface of the second conductive layer to form a third conductive layer.

[0051] In the present invention, the first conductive layer containing the conducti...

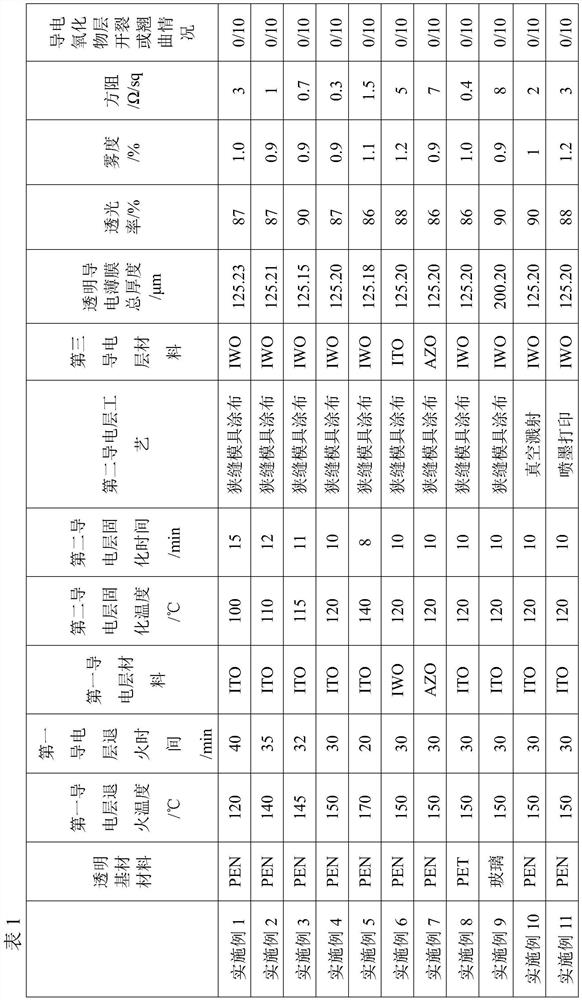

Embodiment 1

[0084]

[0085] The first conductive layer of ITO was prepared on the surface of a PEN transparent substrate with a thickness of 125 μm by vacuum magnetron sputtering, and then annealed at a temperature of 120° C. and an annealing time of 40 min. The thickness of the first conductive layer was 100 nm.

[0086]

[0087] After the nano-silver wires and anhydrous ethanol are mixed and dispersed uniformly, a nano-metal wire paste with a concentration of 8 mg / ml is obtained. The nanowires are 20 μm in length and 30 nm in diameter.

[0088]The nano metal wire slurry was coated on the surface of the first conductive layer through a slit coating die, and the second conductive layer was formed after curing; wherein the curing temperature was 100° C. and the curing time was 15 minutes. The thickness of the second conductive layer is 80 nm, that is, the thickness of the nano-silver wire layer, the line width of the nano-silver wire is 20 μm, and the line spacing is 500 μm.

[0089]...

Embodiment 2

[0092] Except in , the annealing temperature of the first conductive layer is 140°C, the annealing time is 35min, and the thickness of the first conductive layer is 50 nm; in , the nano metal The concentration of the wire paste is 8mg / ml, the curing temperature is 110°C, the curing time is 12min, and the thickness of the second conductive layer is 120nm; Except that the layer thickness was 40 nm, the rest was the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com