High-power pulse laser power supply circuit

A pulsed laser and power circuit technology, applied in the electrical field, can solve the problems of current stability ripple, the real-time response of the circuit can not meet the high dynamic use environment, etc., which is beneficial to the reduction of the ripple and the improvement of the current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

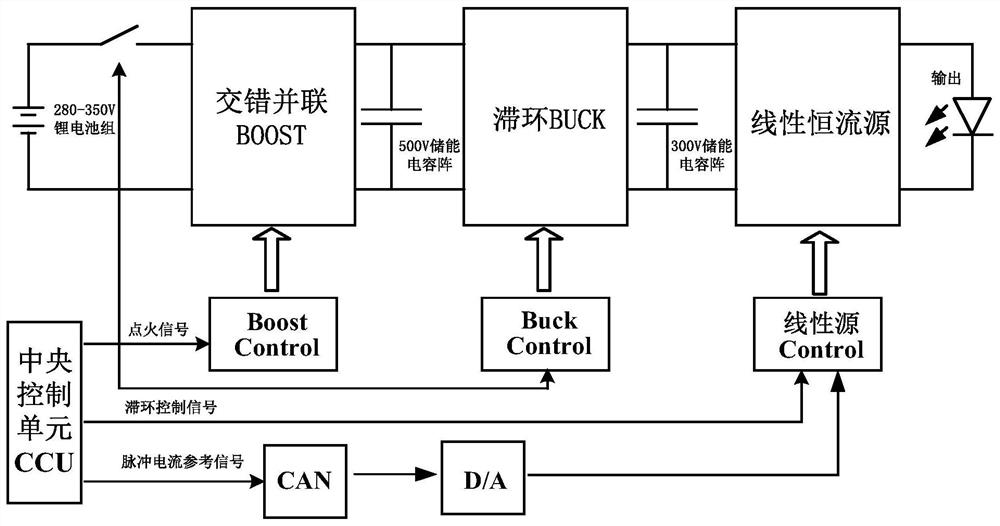

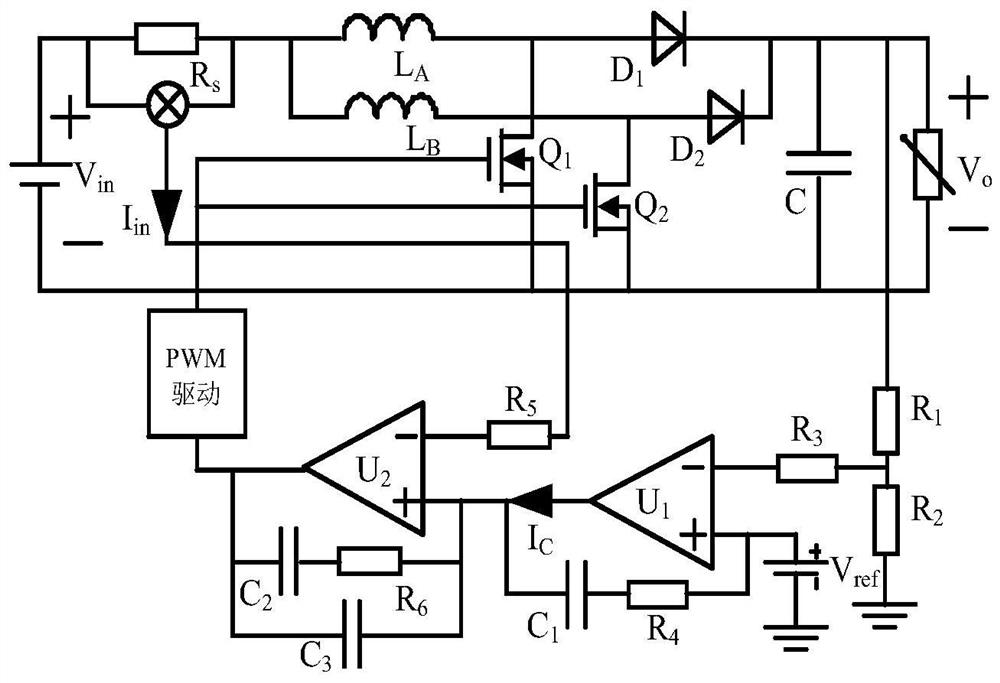

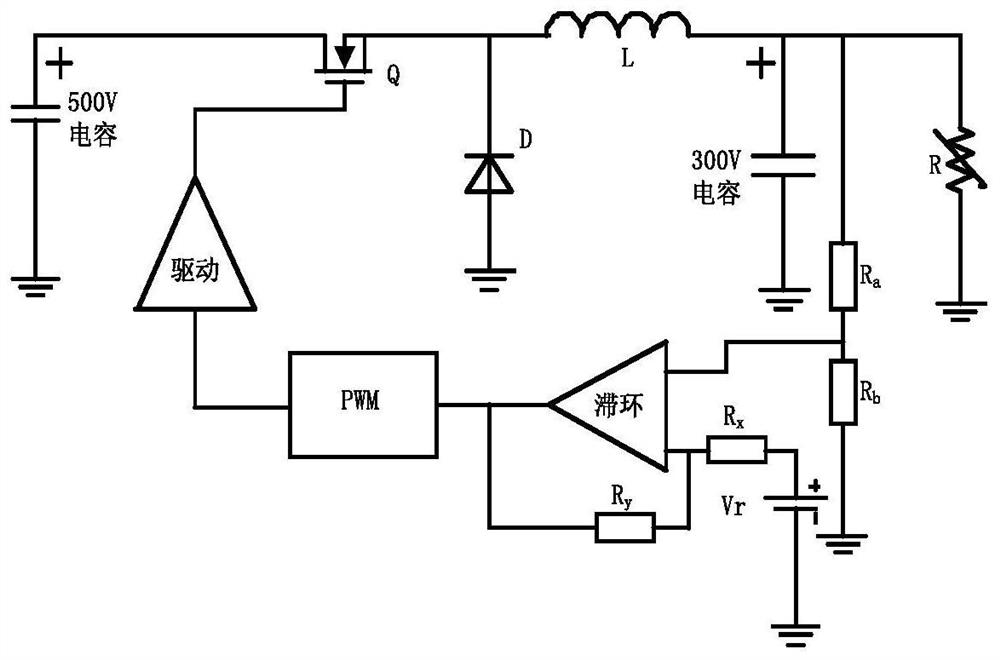

[0023] A high-power pulse laser power supply implementation scheme proposed by the present invention, the overall structure of the circuit is as follows figure 1 As shown, the main circuit includes a DC lithium battery pack, an interleaved parallel BOOST circuit, a 500V energy storage capacitor array, a hysteresis loop BUCK circuit, a 300V energy storage capacitor array, a linear constant current source circuit, and a diode array load. The control part includes a BOOST circuit control module , BUCK circuit control module, linear constant current source control module, CAN communication and D / A digital-to-analog conversion module. The high-power pulsed laser power supply controls the interleaved parallel BOOST circuit, the hysteresis BUCK circuit and the linear constant current source circuit respectively through the ignition signal sent by the central control unit CCU...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com