Intelligent control system for unattended substation

An intelligent control system and substation technology, applied in the cooling/ventilation of substation/switchgear, components of transformer/inductor, and layout details of substation/switch, etc. good condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

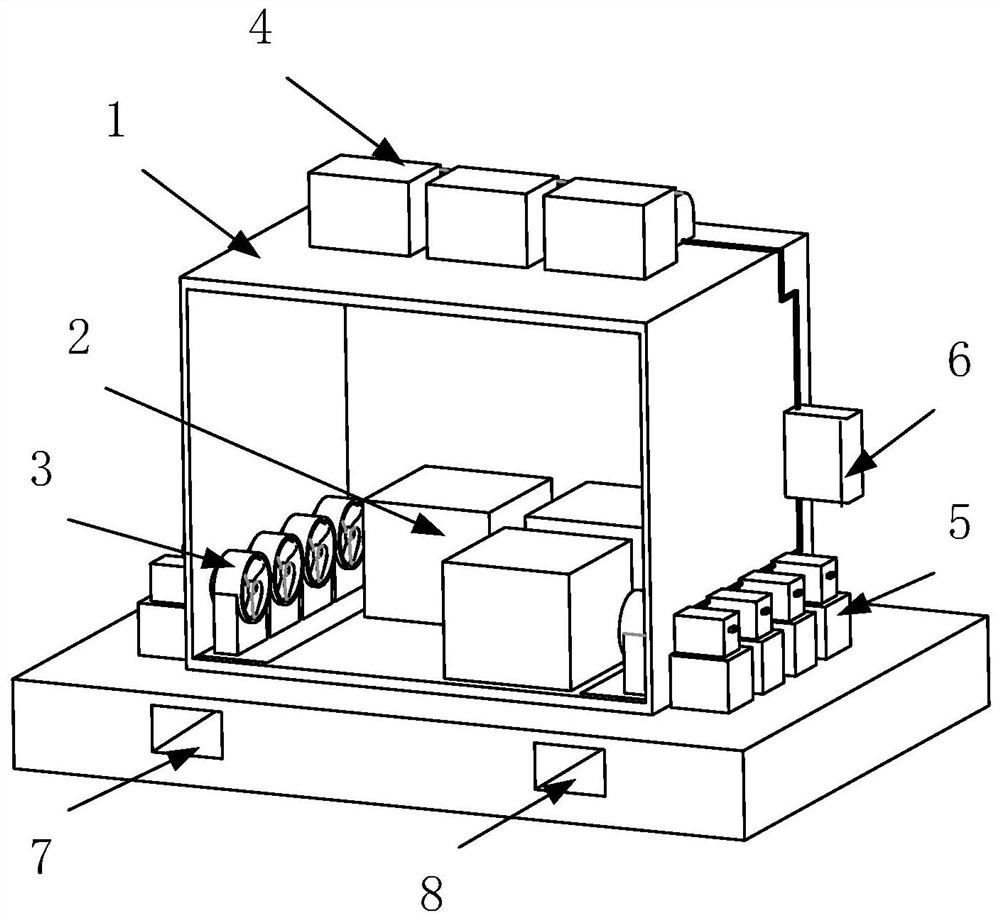

[0025] An intelligent control system for unattended substations of the present application, unattended substations such as figure 1 As shown, it includes a substation house 1 , a transformer assembly 2 , and a ventilation system, and the transformer assembly 2 is set in the transformer substation house 1 . The ventilation system includes an air induction subsystem, an air extraction subsystem, and a controller. The controller is connected to the air induction subsystem and the air extraction subsystem respectively, and is used to detect and control the air induction subsystem and the air extraction subsystem.

[0026] The induced air subsystem includes an induced air assembly 3, an induced air channel 7, an induced air assembly 5, and an induced air channel 8. The induced air assembly 3 is arranged on a side wall of the transformer substation house 1, and its air outlet faces the transformer assembly. The air inlet communicates with the air-inducing channel 7; correspondingly,...

specific Embodiment 2

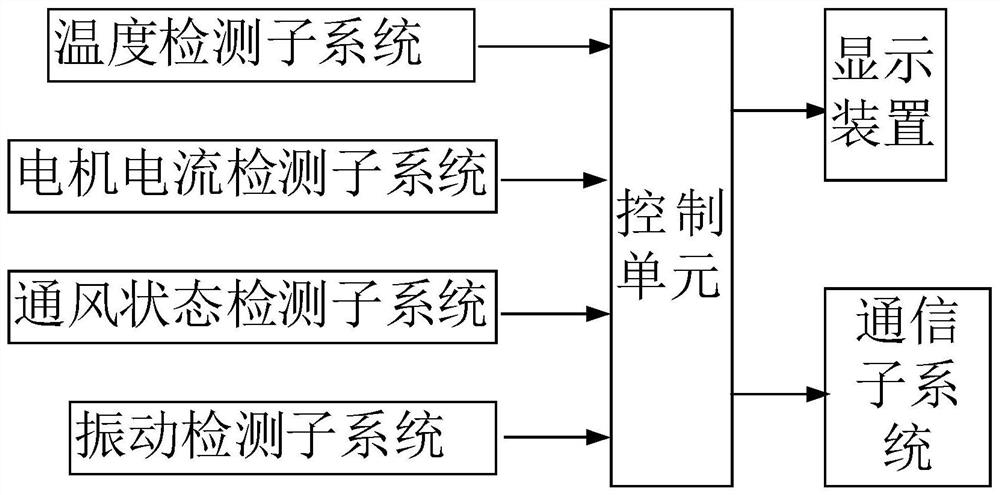

[0038] An intelligent control system for an unattended substation of the present application, the controller includes a control unit, a vibration detection subsystem, a temperature detection subsystem, a ventilation motor current detection subsystem, a ventilation volume detection subsystem, a display device, and a communication subsystem system.

[0039] The vibration detection subsystem includes vibration sensors, which are installed on each ventilation motor to detect whether the ventilation motor vibrates, and to confirm whether the blades and bearings of the ventilation motor are running in balance.

[0040] The temperature detection subsystem includes multiple temperature sensors. One temperature sensor is installed on the shaft of each ventilation motor. After the bearing is damaged, the bearing becomes larger due to friction and the bearing temperature rises. The temperature sensor is used to detect whether the bearing of the ventilation motor is overheated. To confirm...

specific Embodiment 3

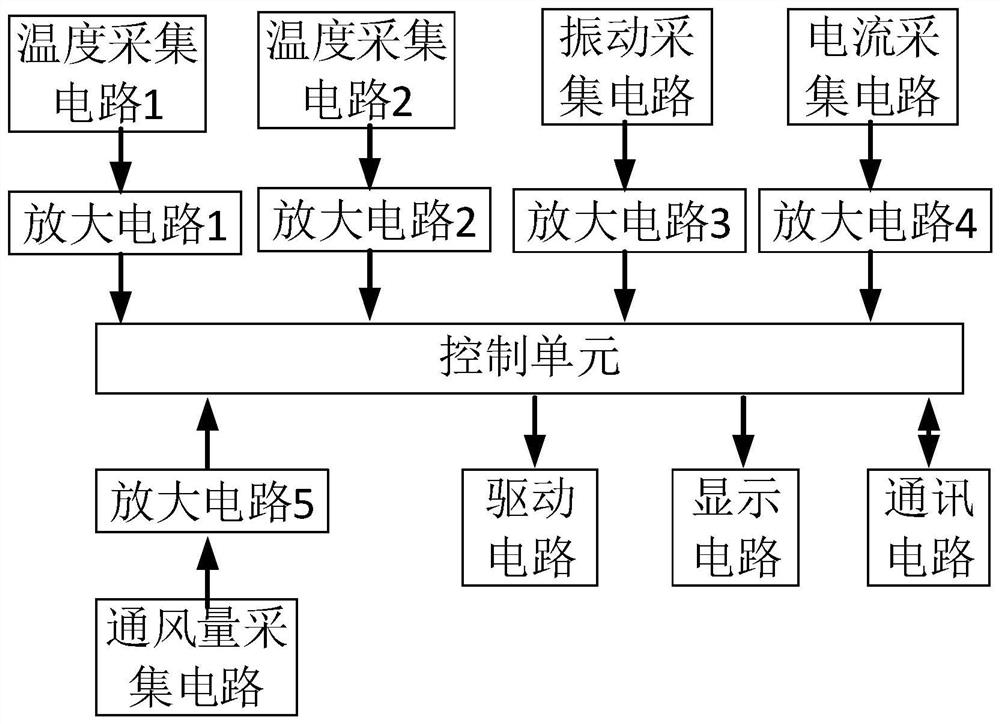

[0055] An intelligent control system for an unattended substation of the present application, such as image 3 As shown, it includes a control unit, a temperature acquisition circuit 1, a temperature acquisition circuit 2, a vibration acquisition circuit, a current acquisition circuit, a ventilation volume acquisition circuit, an amplification circuit 1-5, a drive circuit, a display circuit, and a communication circuit.

[0056] Wherein, the output of the temperature collecting circuit 1 is connected to the input of the amplifying circuit 1, and the output of the amplifying circuit 1 is connected to the control unit circuit for collecting the temperature of the transformer.

[0057] The output of the temperature acquisition circuit 2 is connected to the input of the amplifying circuit 2, and the output of the amplifying circuit 2 is connected to the control unit circuit for collecting the temperature of each ventilation motor bearing.

[0058] The output of the vibration acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com