Feed produced by treating green cakes through steam explosion and method

A technology of aquatic feed and green cake, applied in animal feed, animal feed, forming or processing of animal feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

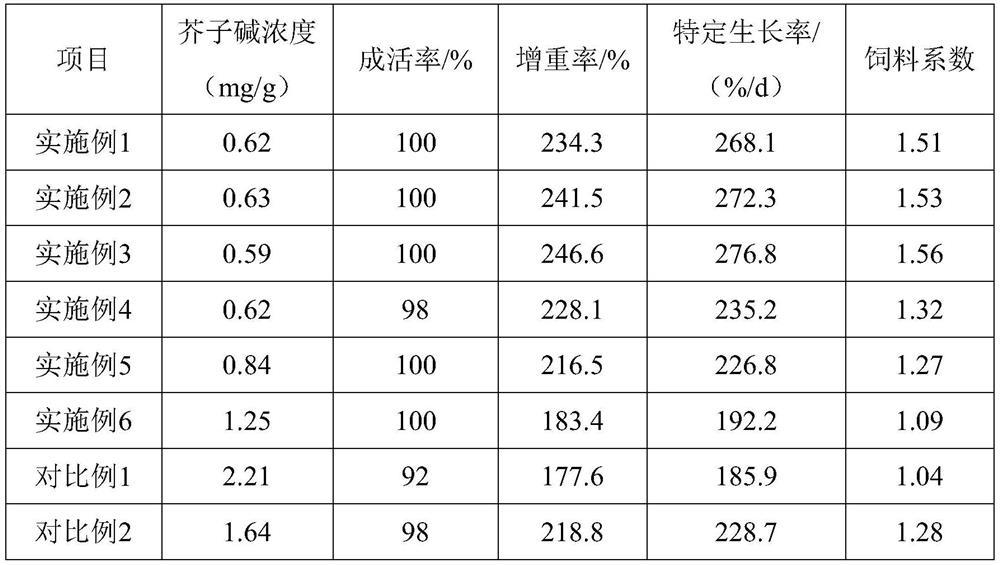

Examples

Embodiment 1

[0027] S1, crush the green cake to 80 mesh and sieve, spray polyglycerol ester and 20% ammonia water into the green cake particles, the mass ratio of green cake: polyglycerol ester: 20% ammonia water is 100:2:10, stir evenly Finally, steam is introduced to heat the material to 100-110°C, the reactor pressure is at 1.2Mpa, react for 8 minutes, and then quickly open the reactor valve to carry out steam explosion treatment on the green cake; after the steam explosion, the green cake is under the heating condition Stir and dry down, so that the moisture content of the green cake after pretreatment is ≤10%;

[0028] S2. After crushing 35 parts of pretreated green cake, 25 parts of soybean meal, 15 parts of rice bran, 9 parts of distiller's grains, 6 parts of wheat bran, 0.5 part of fish meal and 12 parts of barley, add Fe, Cu, Mn, Zn and Co 3 parts of amino acid chelate, perilla, Codonopsis pilosula, cypress, poria cocos and licorice are stirred and mixed with Chinese herbal medici...

Embodiment 2

[0032] S1, crush the green cake to 30 mesh and sieve it, spray polyglycerol ester and 20% ammonia water into the green cake particles, the mass ratio of green cake: polyglycerol ester: 20% ammonia water is 100:5:15, stir evenly Finally, steam is introduced to heat the material to 100-110°C, the reactor pressure is 0.6Mpa, react for 15 minutes, and then quickly open the reactor valve to carry out steam explosion treatment on the green cake; after the steam explosion, the green cake is heated under the Stir and dry down, so that the moisture content of the green cake after pretreatment is ≤10%;

[0033] S2. After pretreatment, 25 parts of green cake, 35 parts of soybean meal, 10 parts of rice bran, 10 parts of distiller's grains, 4 parts of wheat bran, 1.5 parts of fish meal, and 8 parts of barley are pulverized, and then Fe, Cu, Mn, Zn and Co are added 5 parts of amino acid chelate, perilla, Codonopsis pilosula, cypress, poria cocos and licorice are stirred and mixed with micro...

Embodiment 3

[0037] S1, crush the green cake to 50 mesh and sieve it, spray polyglycerol ester and 20% ammonia water into the green cake particles, the mass ratio of green cake: polyglycerol ester: 20% ammonia water is 100:3.5:12, stir evenly Finally, steam is introduced to heat the material to 100-110°C, the reactor pressure is 0.9Mpa, react for 11 minutes, and then quickly open the reactor valve to carry out steam explosion treatment on the green cake; after the steam explosion, the green cake is under the heating condition Stir and dry down, so that the moisture content of the green cake after pretreatment is ≤10%;

[0038] S2. After pretreatment, 30 parts of green cake, 30 parts of soybean meal, 22 parts of rice bran, 9.5 parts of distiller's grains, 5 parts of wheat bran, 1 part of fish meal, and 10 parts of barley are pulverized, and then Fe, Cu, Mn, Zn and Co are added 4 parts of amino acid chelate, perilla, Codonopsis pilosula, cypress, poria cocos and licorice are stirred and mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com