Viscosity-adjustable grid exhaust adhesive tape and preparation method thereof

A tape and character technology, applied in the field of adjustable sticky grill exhaust tape and its preparation, can solve the problems of low production efficiency, failure to meet the production demand of battery tape battery tape, low output, etc., and achieve high production efficiency and good pasting effect Good, high temperature viscous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

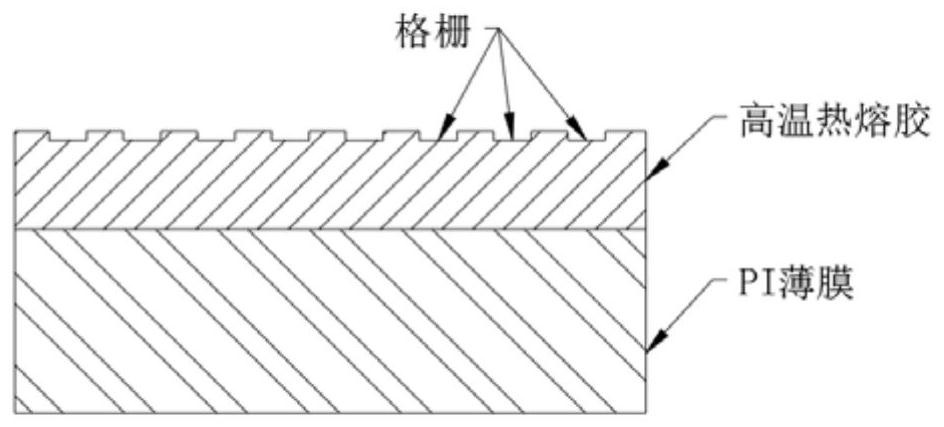

[0060]An adjustable adhesive grid exhaust tape comprising a polyimide film and a high temperature thermal melt glue having a solid content of 35.7%, and the rubber surface of the tape is a grid.

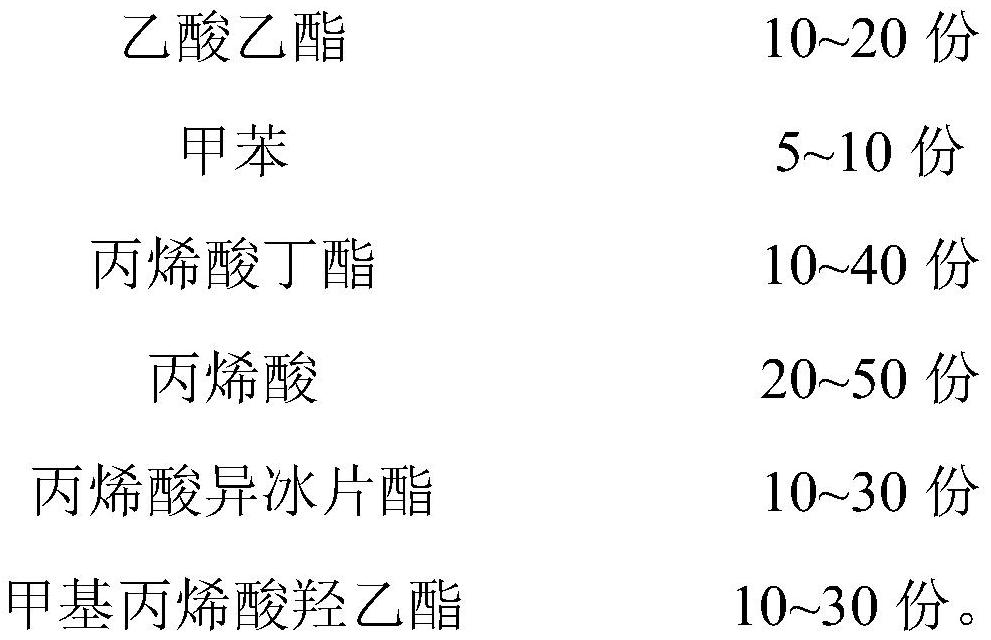

[0061] Further, high temperature hot melt adhesives include the following raw materials, according to the weight:

[0062]

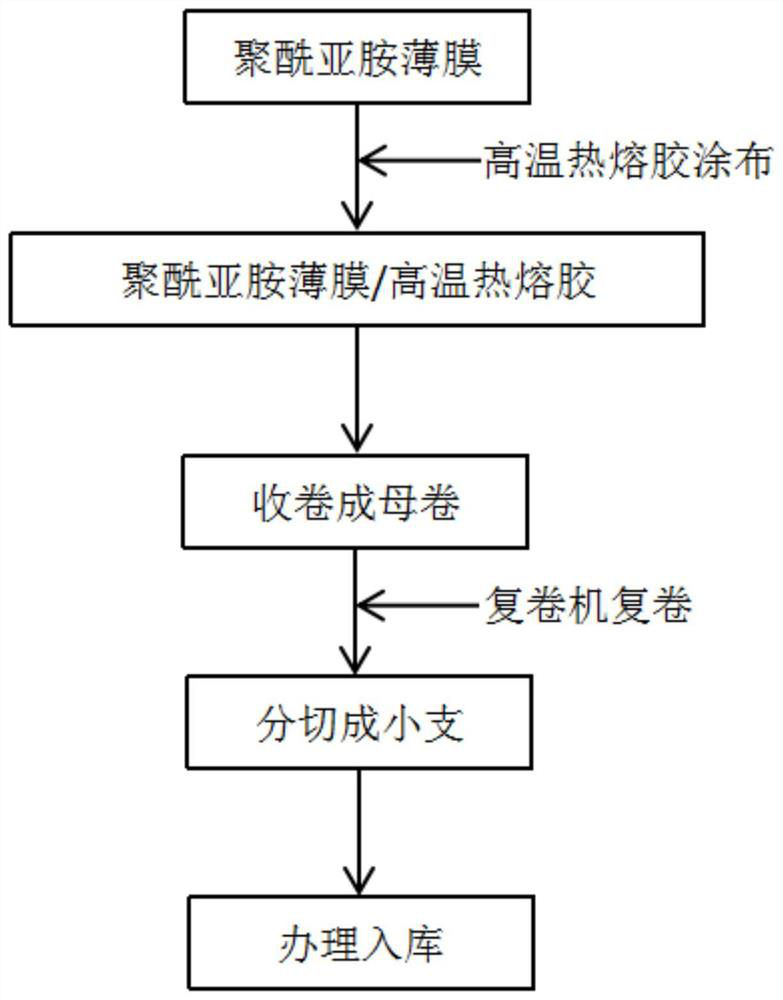

[0063] The method of preparing the above-mentioned adhesive grating veneer, including the following steps:

[0064] Step (1): The high-temperature hot melt is directly applied directly to the surface of the polyimide film of 25 μm, and then drying the thickness of 5 μm at 110 ° C to give a prefabricated tape having a thickness of 30 μm;

[0065] Step (2): Eliminate the preposition of the prefabricated tape through the roller roller, so that the glue surface is pressed into a grid, obtain a roller tape, and then retract the roll tape, rewind, and obtain the finished tape.

[0066] Wherein, the roller has a grid pressure roller having a convex body strip parallel t...

Embodiment 2

[0068] An adjustable adhesive grid exhaust tape comprising a polyimide film and a high temperature hot melt glue.

[0069] The difference from Example 1 is that the high temperature thermal melt glue solid content is 20%, and the feedstock is measured by weight:

[0070]

[0071] The remaining settings are the same as in Example 1.

Embodiment 3

[0073] An adjustable adhesive grid exhaust tape comprising a polyimide film and a high temperature hot melt glue.

[0074] The difference from Example 1 is that the high temperature thermal melt adhesive solid content is 30%, and its feedstock is subjected to a mass:

[0075]

[0076] The remaining settings are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com