Pyrometallurgical lead smelting device and lead smelting process

A technology of lead smelting and fire method, which is applied in the field of fire method lead smelting equipment and technology, to achieve the effects of facilitating operation, stabilizing the soot system, and reducing system load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

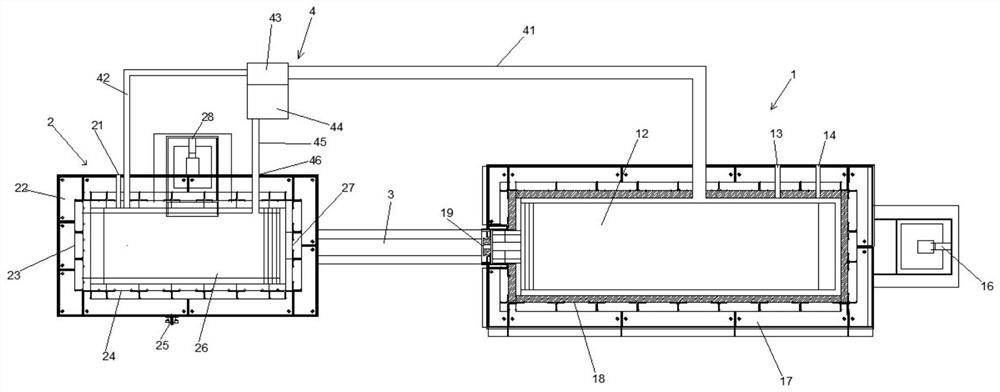

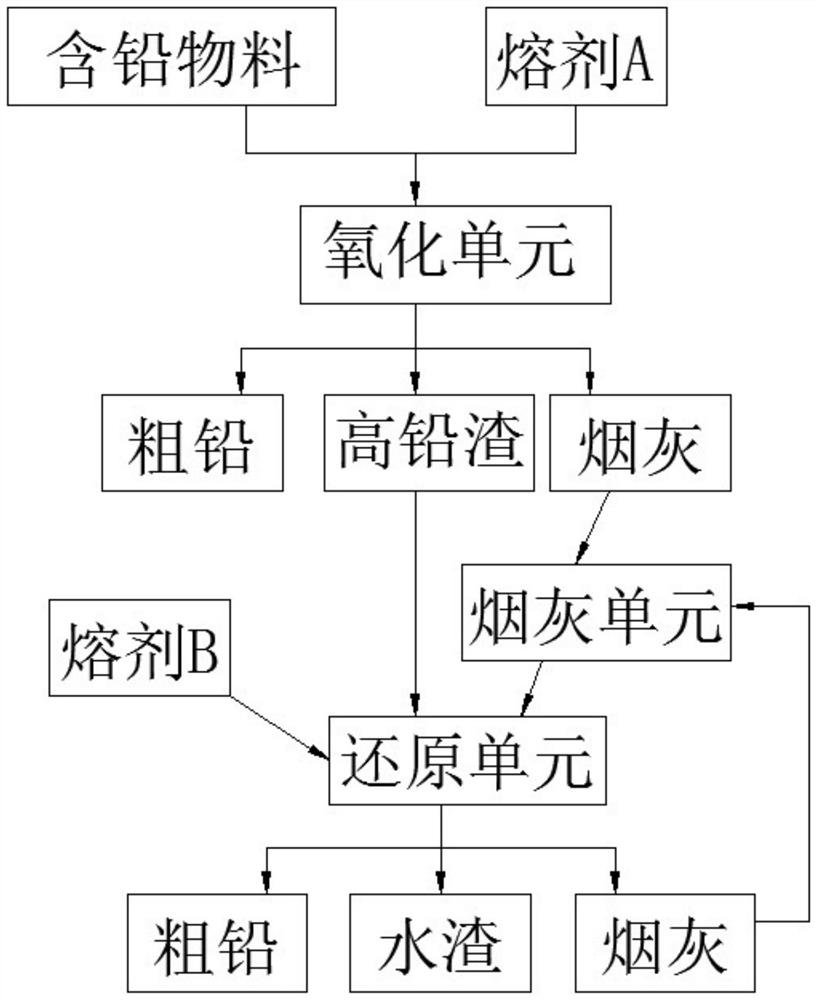

[0040] like figure 1 As shown, the pyrotechnic lead smelting device mainly includes an oxidation unit 1, a reduction unit 2 and a soot unit 4, wherein the soot unit 4 includes a first smoke outlet pipe 41 and a second smoke outlet pipe 42, and the soot unit 4 includes a soot treatment device 43. The granulation device 44, wherein the first smoke outlet pipe 41 and the second smoke outlet pipe 42 are both connected to the soot treatment device 43, and the soot treatment device 43 is provided with an induced draft fan. The oxidation unit 1 and the reduction unit 2 are connected through the slag chute 3 . The oxidation unit 1 is provided with a first slag outlet 19, which is connected to one end of the slag chute 3, and the reduction unit 2 is provided with a first slag inlet 27, the first slag inlet 27 and the slag chute 3 the other end of the connection.

[0041] The oxidation unit 1 includes a first frame 17 , a first copper water jacket 18 is arranged on the inner surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com