Gas supply system and method for gasification air of electrostatic precipitation ash hopper

A gas supply system, electrostatic precipitator technology, applied in the field of electrostatic precipitator system, electrostatic precipitator ash hopper gasification air supply system, can solve problems such as air supply temperature and flow can not be guaranteed, electrostatic precipitator withdrawal, affect the efficiency of electrostatic precipitator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

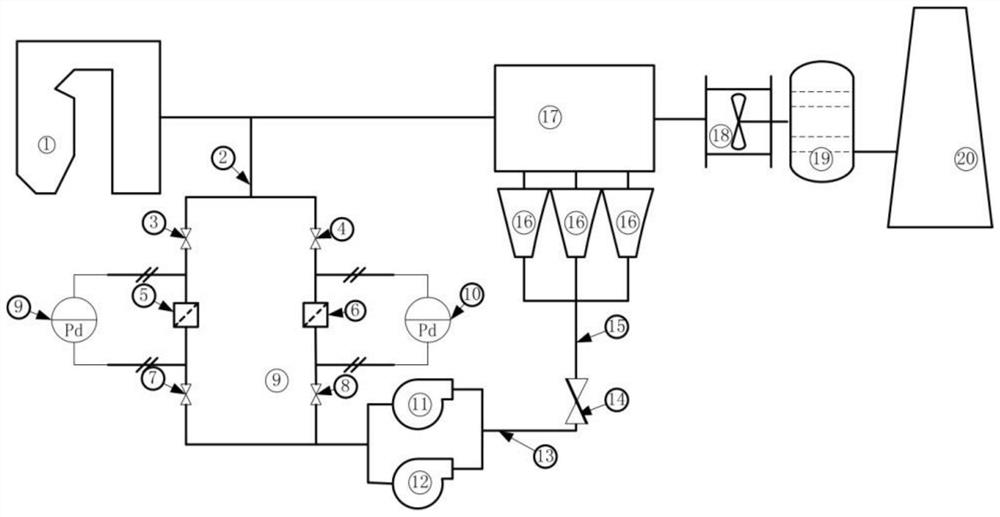

[0026] Such as figure 1 As shown, the present invention includes a coal-fired boiler 1, an inlet manual door, an outlet manual door, a filter screen, a filter screen differential pressure switch, a gasification fan, a gasification fan outlet pipeline, a gasification fan outlet pneumatic door 14, and an ash hopper gasification wind Pipeline 15, electrostatic precipitator ash hopper 16, electrostatic precipitator 17, induced draft fan 18, desulfurization tower 19 and chimney 20. The flue gas outlet of the coal-fired boiler 1 is divided into two paths, one of which is connected to the filter screen through the inlet pipe 2, and the other path is connected to the flue gas inlet of the electrostatic precipitator 17. The filter is a side-by-side double filter, with a manual door at the entrance and a manual door at the exit. The flue gas pipeline at the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com