Device and method for testing water line corrosion resistance of stainless steel pipe

A stainless steel tube, corrosion performance technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, analysis materials, etc., can solve the problems of expensive stainless steel, low usage, and lack of evaluation methods and test devices for stainless steel waterline corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

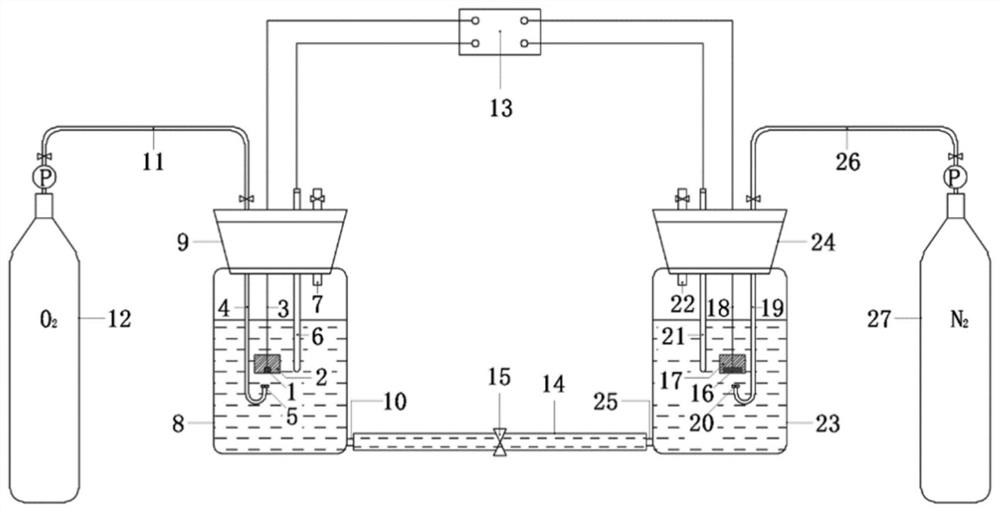

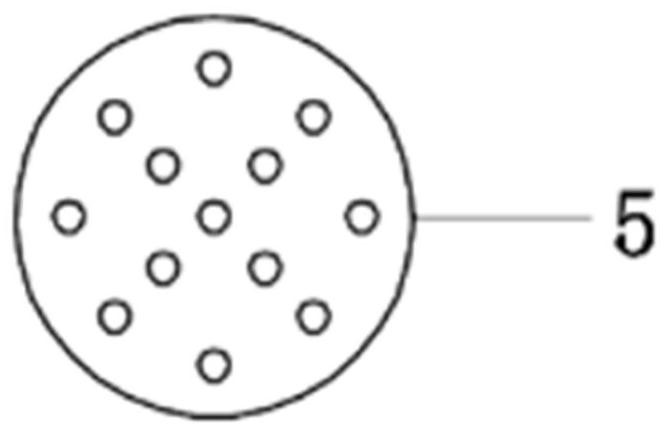

[0027] Such as figure 1 As shown, a stainless steel pipe waterline corrosion resistance test device includes an electrochemical workstation 13, an anode chamber 8 and a cathode chamber 23, the lower end side walls of the anode chamber 8 and the cathode chamber 23 are all provided with openings, and the anode chamber The opening of the lower side wall of the chamber 8 communicates with the opening of the lower end side wall of the cathode chamber 23 through the connecting pipe 14; One end of the anode reference electrode 6 and the anode reference electrode 6 are all connected to the electrochemical workstation 13, the other end of the anode lead 3 is connected to the anode sample 1, and the other end of the anode reference electrode 6 and the anode sample 1 are all located in the test solution in the anode chamber 8. At the lower end of the liquid surface, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com