Ferroelectric memory

A memory, ferroelectric technology, applied in the direction of electric solid devices, circuits, capacitors, etc., can solve problems such as non-conformity, and achieve the effect of increasing the number of operations, stabilizing ferroelectric properties, and slowing down operational deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The volume percentage of different crystal phases in the ferroelectric layer under certain conditions

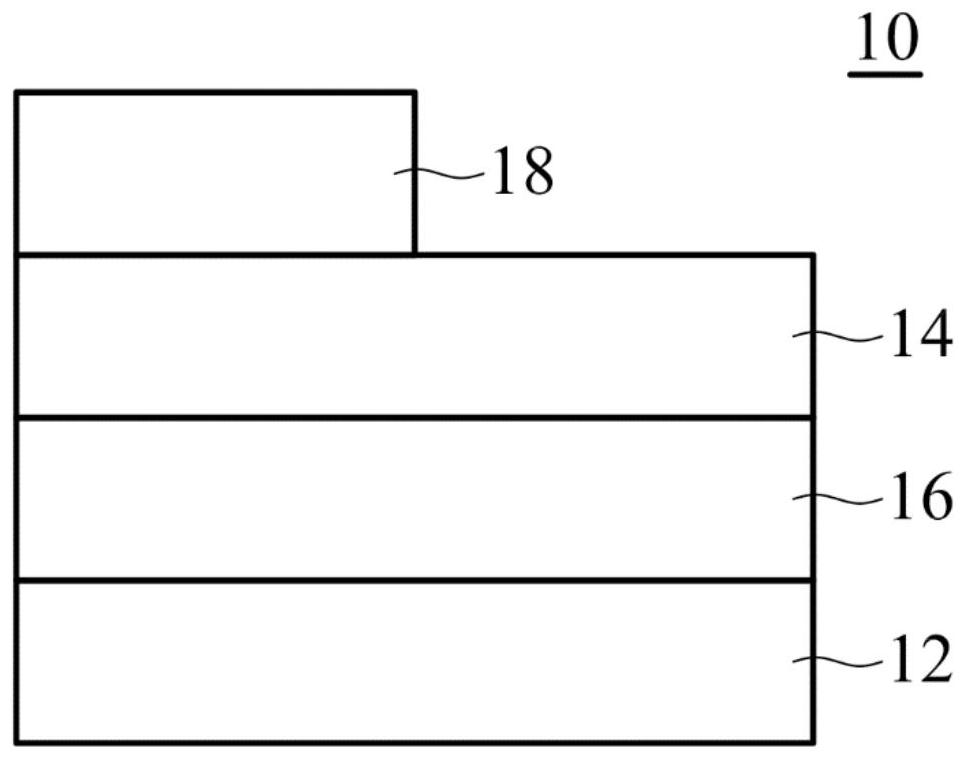

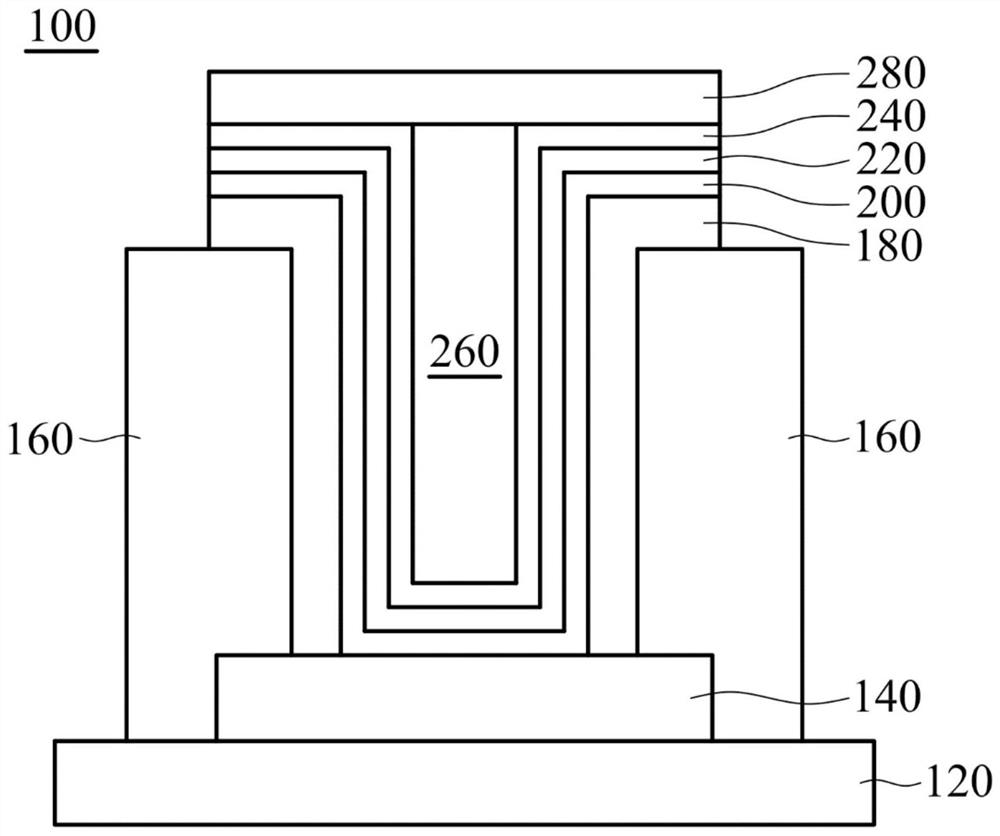

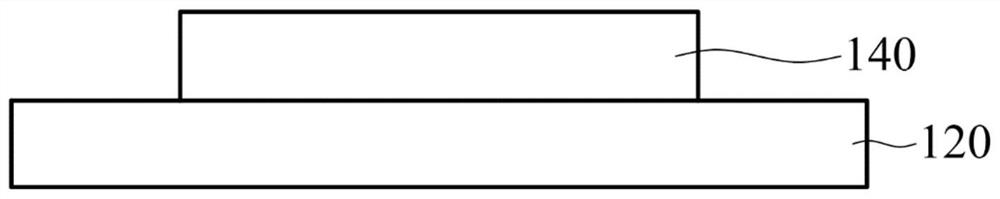

[0048] In this embodiment, under specific conditions, different crystalline phases (including monoclinic phase, M-phase), orthorhombic phase (orthorhombic phase, O-phase), and tetragonal phase (tetragonal phase, T-phase)) accounted for the volume percentage to verify, wherein the monoclinic phase (M-phase) corresponds to Dielectric properties are generated, the orthorhombic phase (O-phase) corresponds to ferroelectric properties, and the tetragonal phase (T-phase) corresponds to antiferroelectric properties. The device structure of ferroelectric memory I, ferroelectric memory II, and ferroelectric memory III is as follows figure 1 shown. The ferroelectric layer of ferroelectric memory I is made of hafnium zirconium oxide (HfZrO x ), the first and second electrode layers are made of titanium nitride (TiN), and the main crystallographic directions of the first and seco...

Embodiment 2

[0053] The relationship between the number of operations and remanent polarization (Pr) of ferroelectric memory

[0054] In this embodiment, according to the structural configuration of the element device shown in Embodiment 1, under the conditions of applying an electric field intensity of 2.5MV / cm and applying a stress of 1GPa, the ferroelectric memory I and the ferroelectric memory III are subjected to the residual electrode The test of remanent polarization (Pr) changes with the number of operations (cycle), the results are as follows Figure 4 shown.

[0055] Depend on Figure 4 It can be seen that under the above test conditions, when the number of operations is gradually increased, the remanent polarization (Pr) of the ferroelectric memory I (the main crystallographic direction of the titanium nitride (TiN) electrode layer is (100)) increases with the operation It has been seen that there is an obvious wake-up behavior when the number of operations increases, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com