Patents

Literature

30results about How to "Increase the number of operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data buffer device, data storage system and method

InactiveCN102870100AGuaranteed read and write performanceAvoid wastingMemory architecture accessing/allocationError detection/correctionData interfaceComputer science

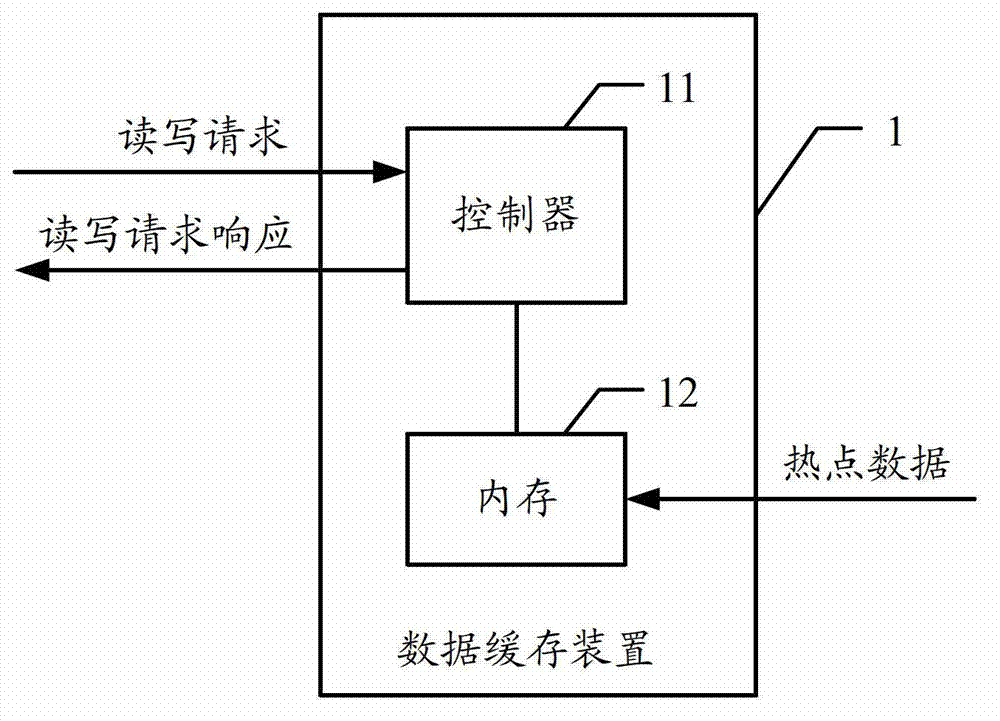

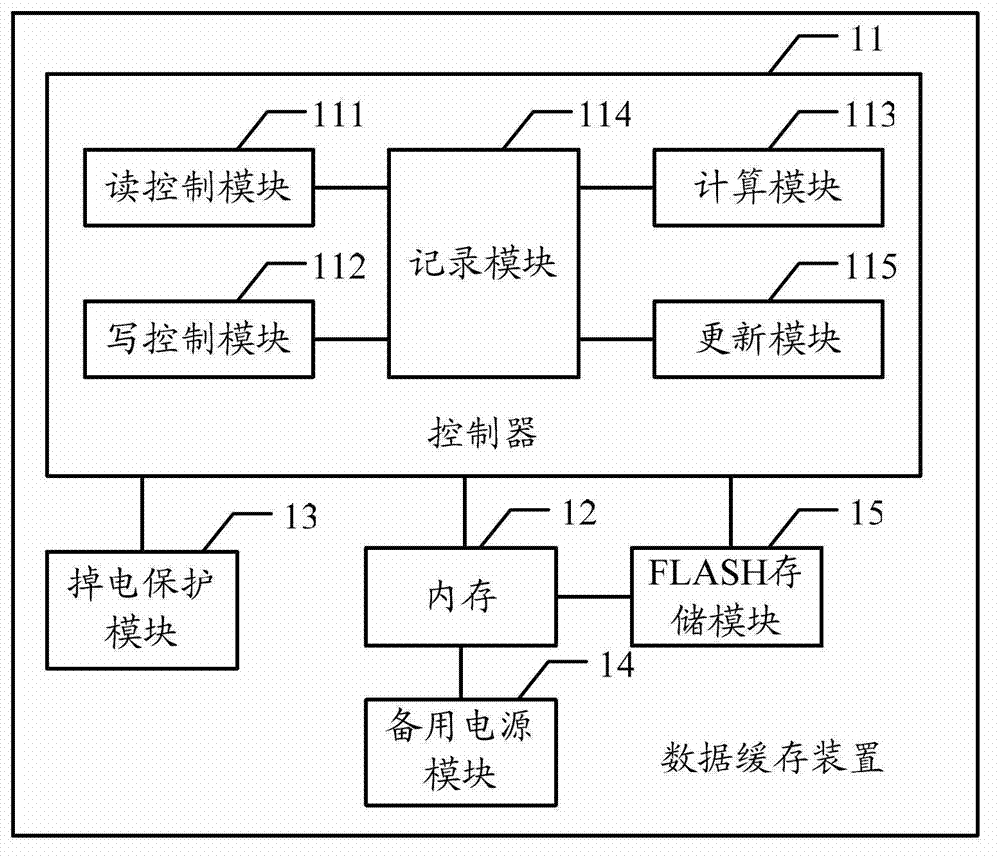

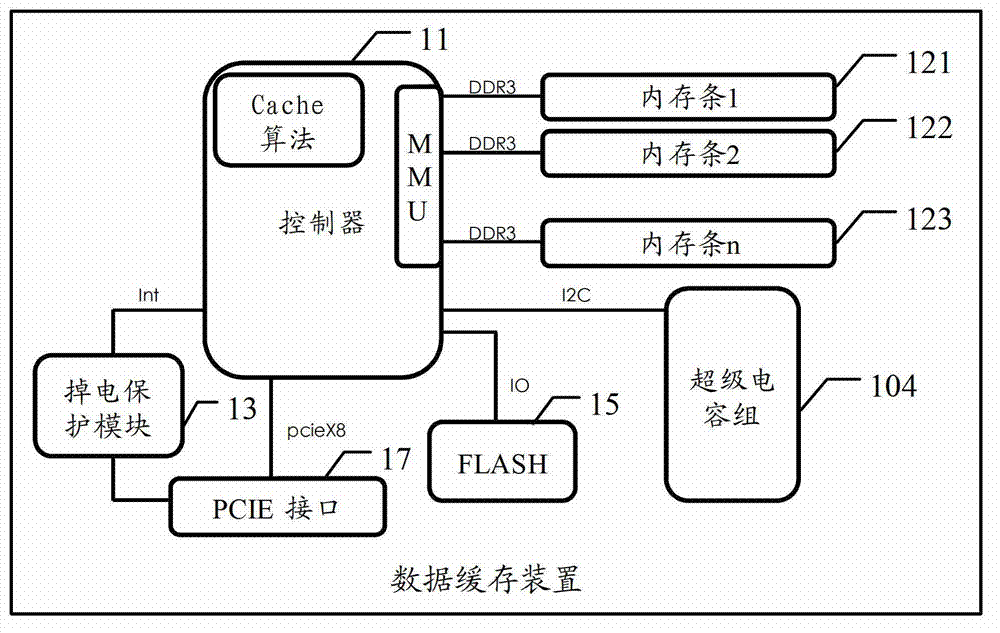

The embodiment of the present invention discloses a data buffer device, a data storage system and a method. The data buffer device is connected to a data processing apparatus through a data interface. The data buffer device includes: a controller, and a memory connected with the controller. The memory is used for caching the hotspot data in a hard disk connected to the data buffer device, and the controller is used to read and write data into the memory according to the requestsof the data processing apparatus. By using the present invention, not only the data read and write performance can be enhanced, and also the waste of system resources can be prevented.

Owner:HUAWEI TECH CO LTD

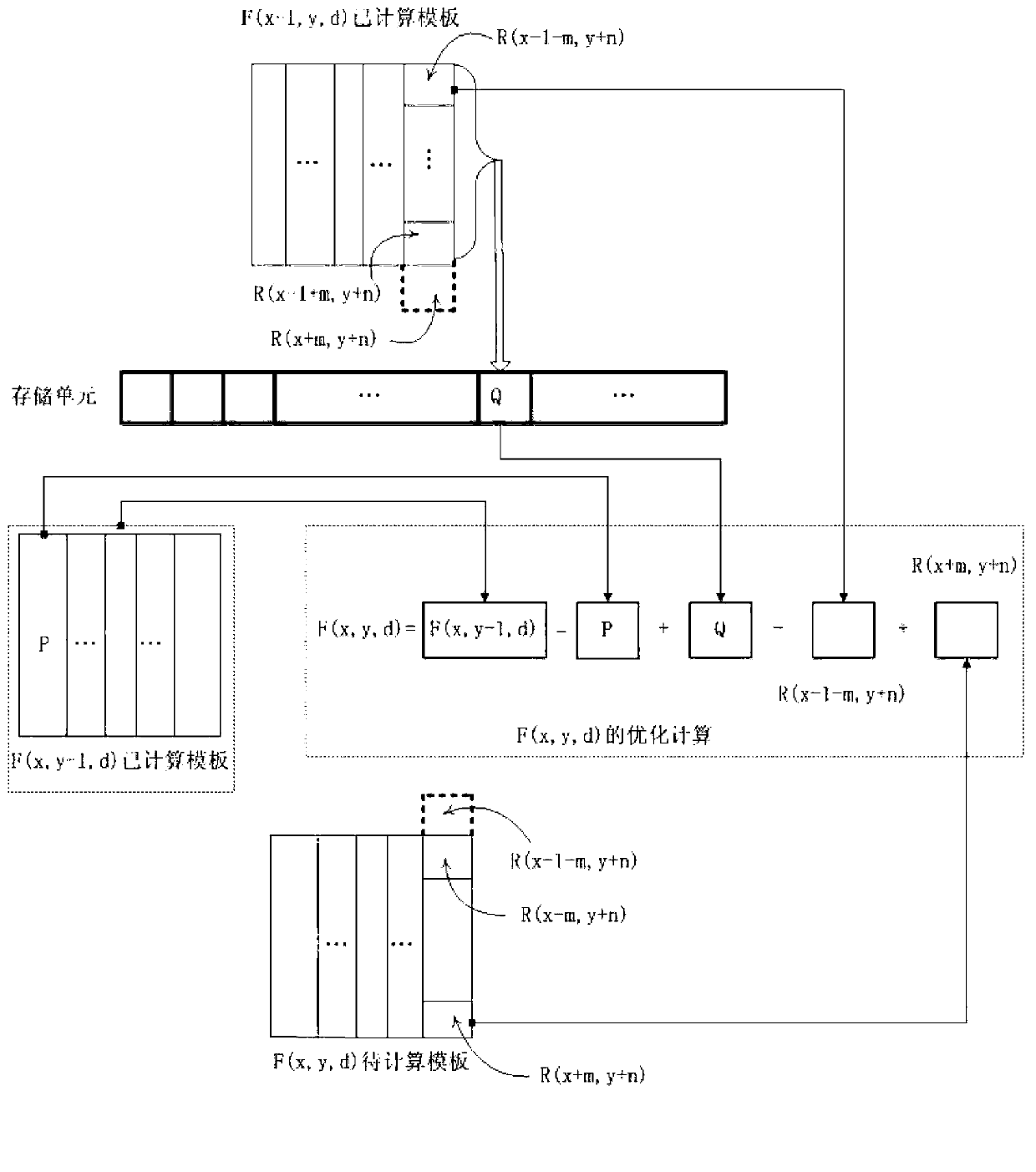

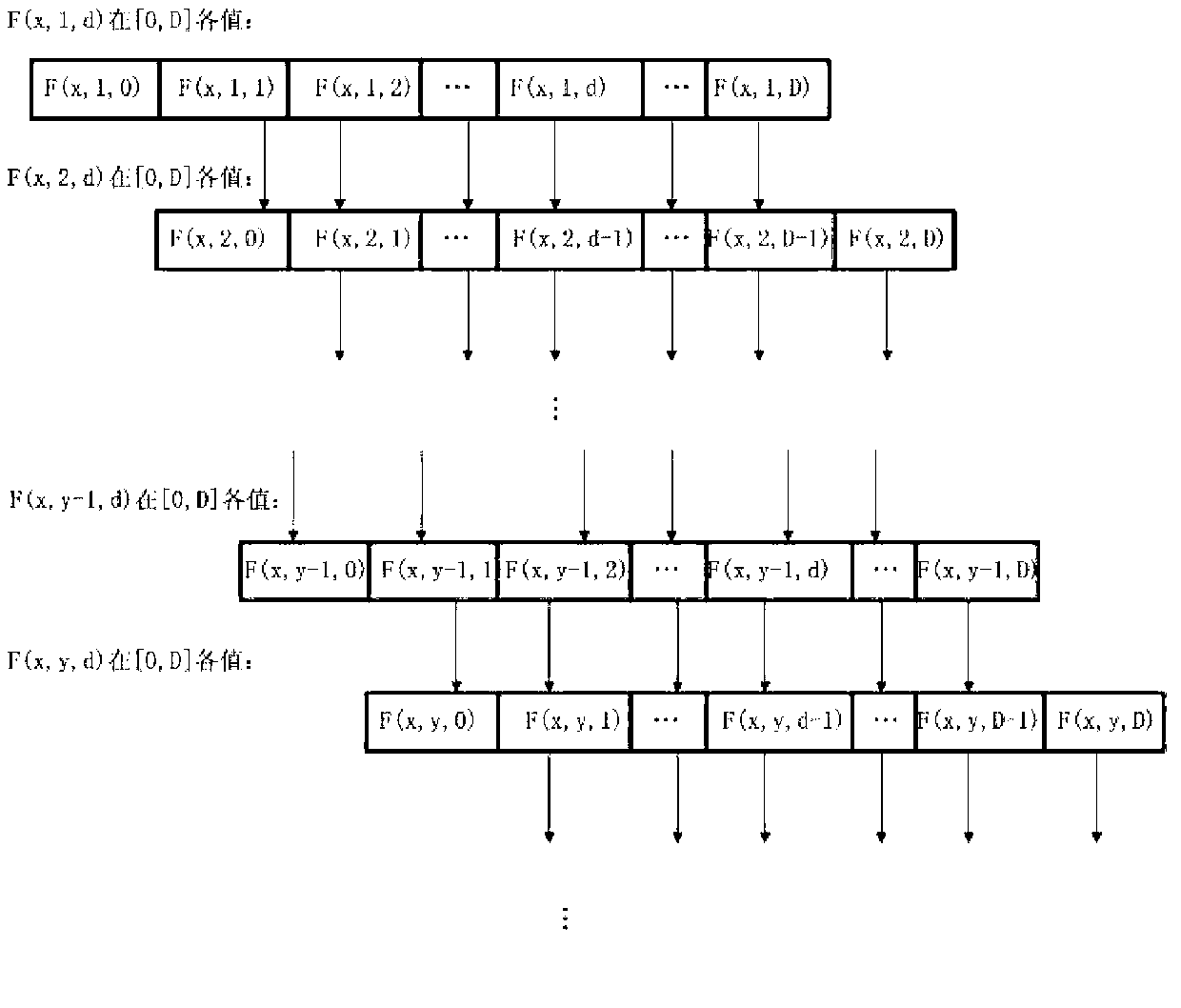

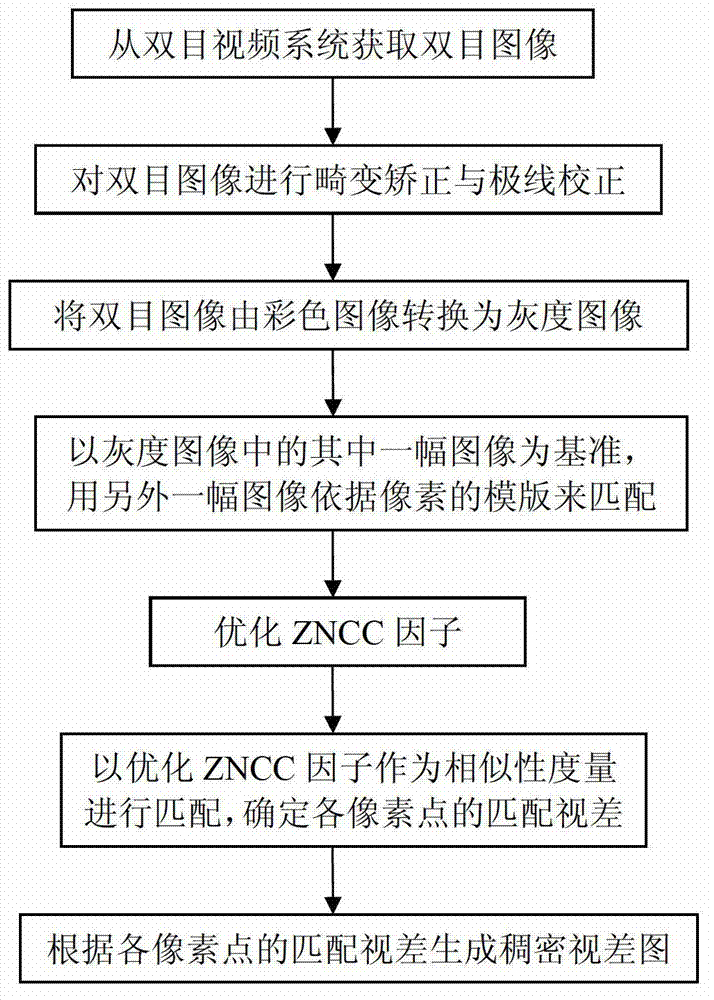

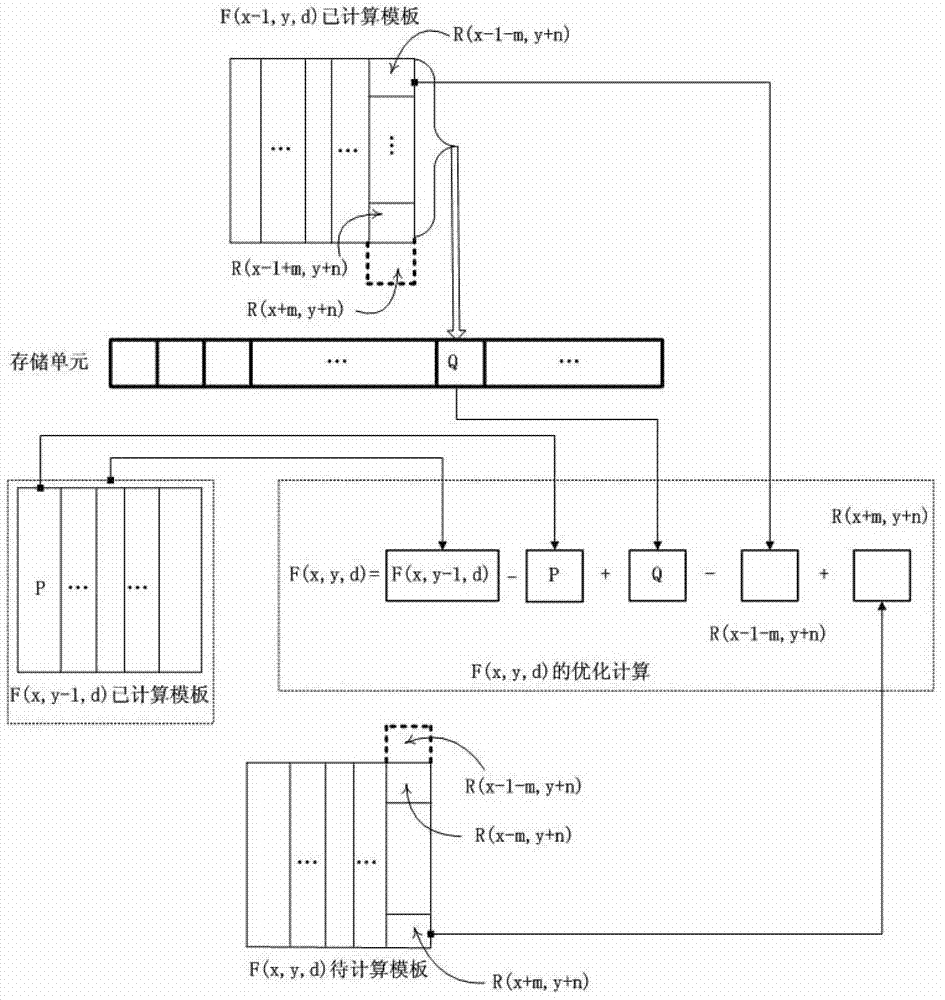

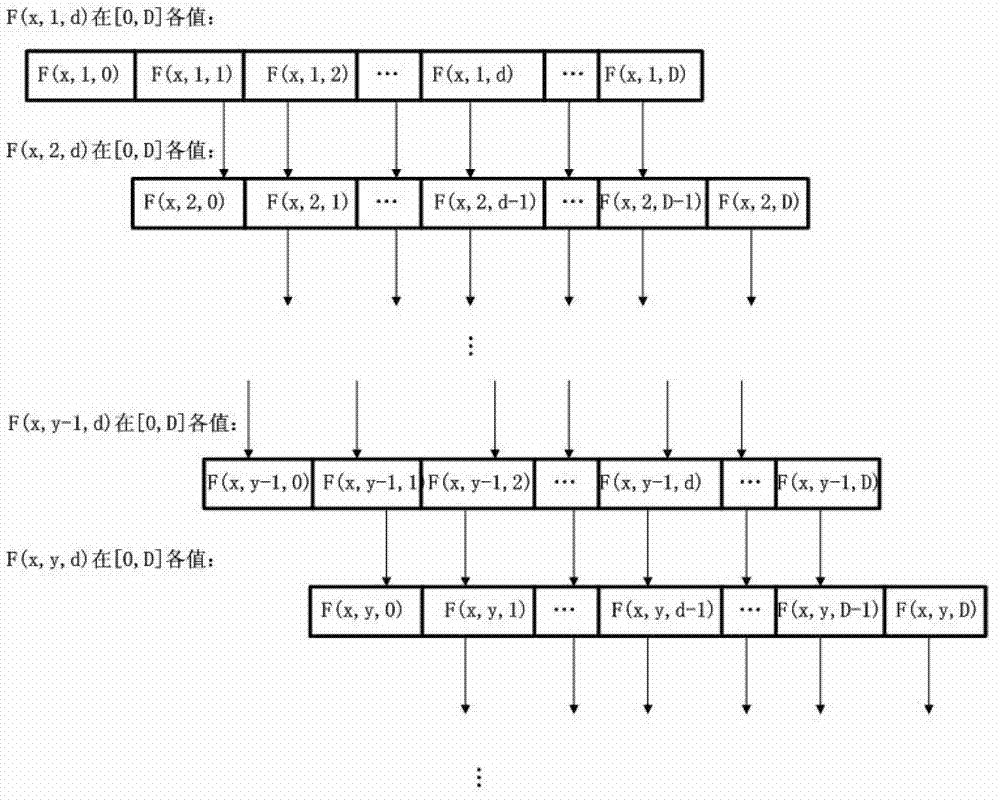

Stereo matching optimization method of binocular visual system

InactiveCN103136750AReduce computing loadReduce the number of operationsImage analysisParallaxStereo matching

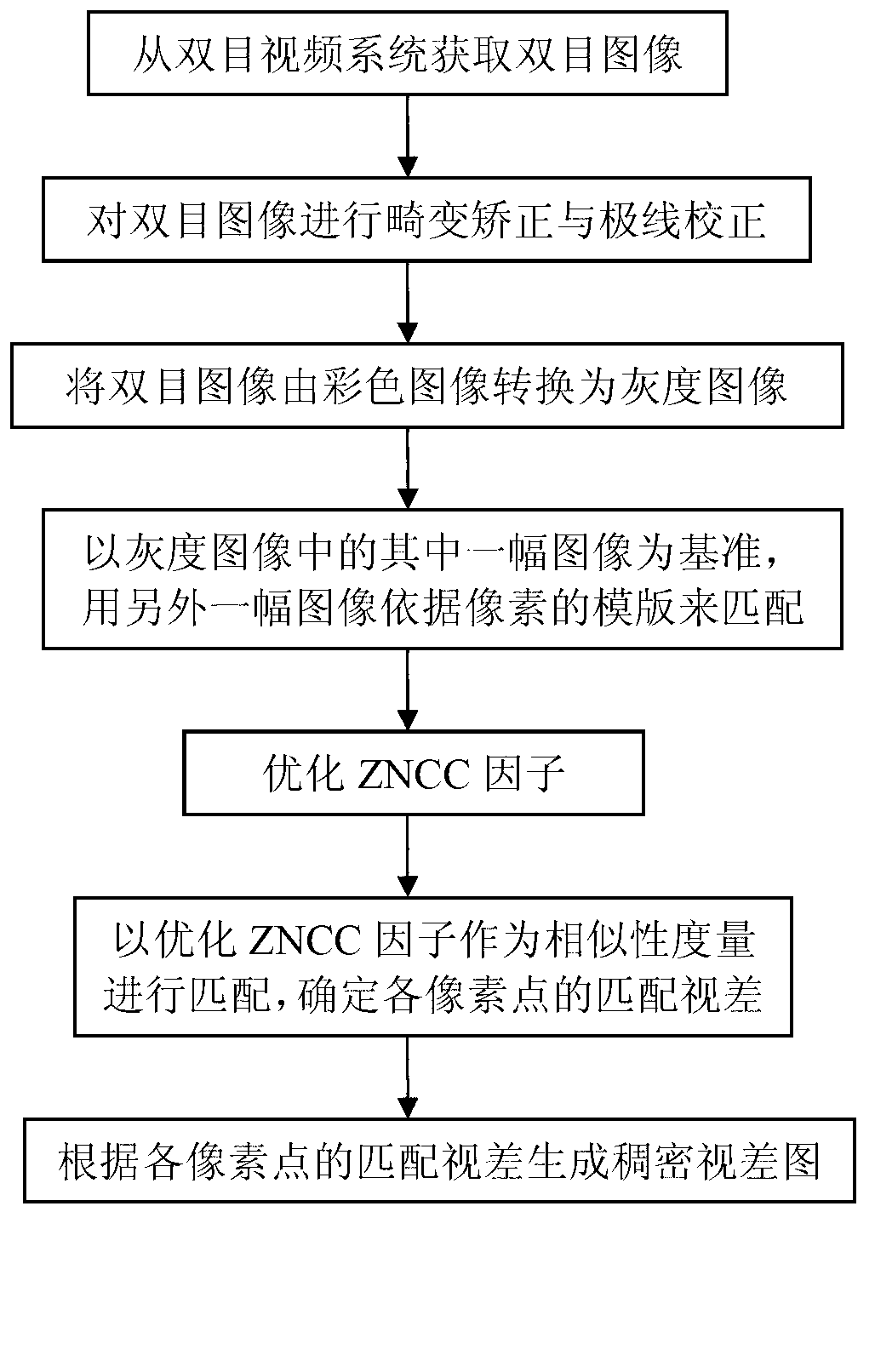

The invention provides a stereo matching optimization method of a binocular visual system. The method comprises a step of using the binocular visual system to gain a binocular image; a step of correcting a distortion and polar line of the binocular visual system; a step of transferring the binocular image from a colorful image into a grayscale image; a step of regarding one of the grayscale images as a basic standard and matching with another image according to pixel masterplate; a step of optimizing ZNCC factor; a step of regarding the optimized ZNCC as a similarity measure to calculate in a matched mode so as to ensure matching parallax of each pixel point; a step of producing a dense disparity map according to the matching parallax of each pixel point. The method has the advantages of reducing times of calculation greatly and reducing calculating load of computer chip greatly by optimizing a computational formula of the ZNCC factors and calculating method. The method can improve real-time performance of the stereo matching as well as reducing cost of day-to-day and military high-precision image identification.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

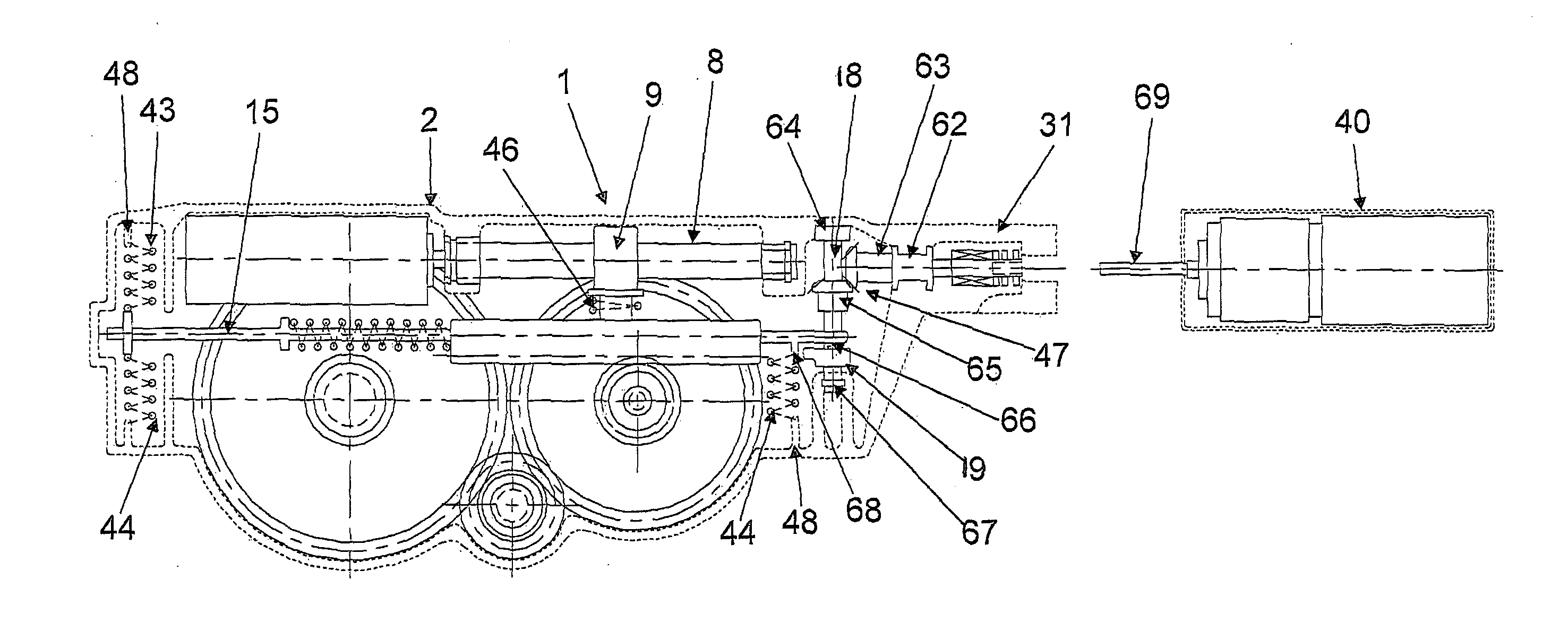

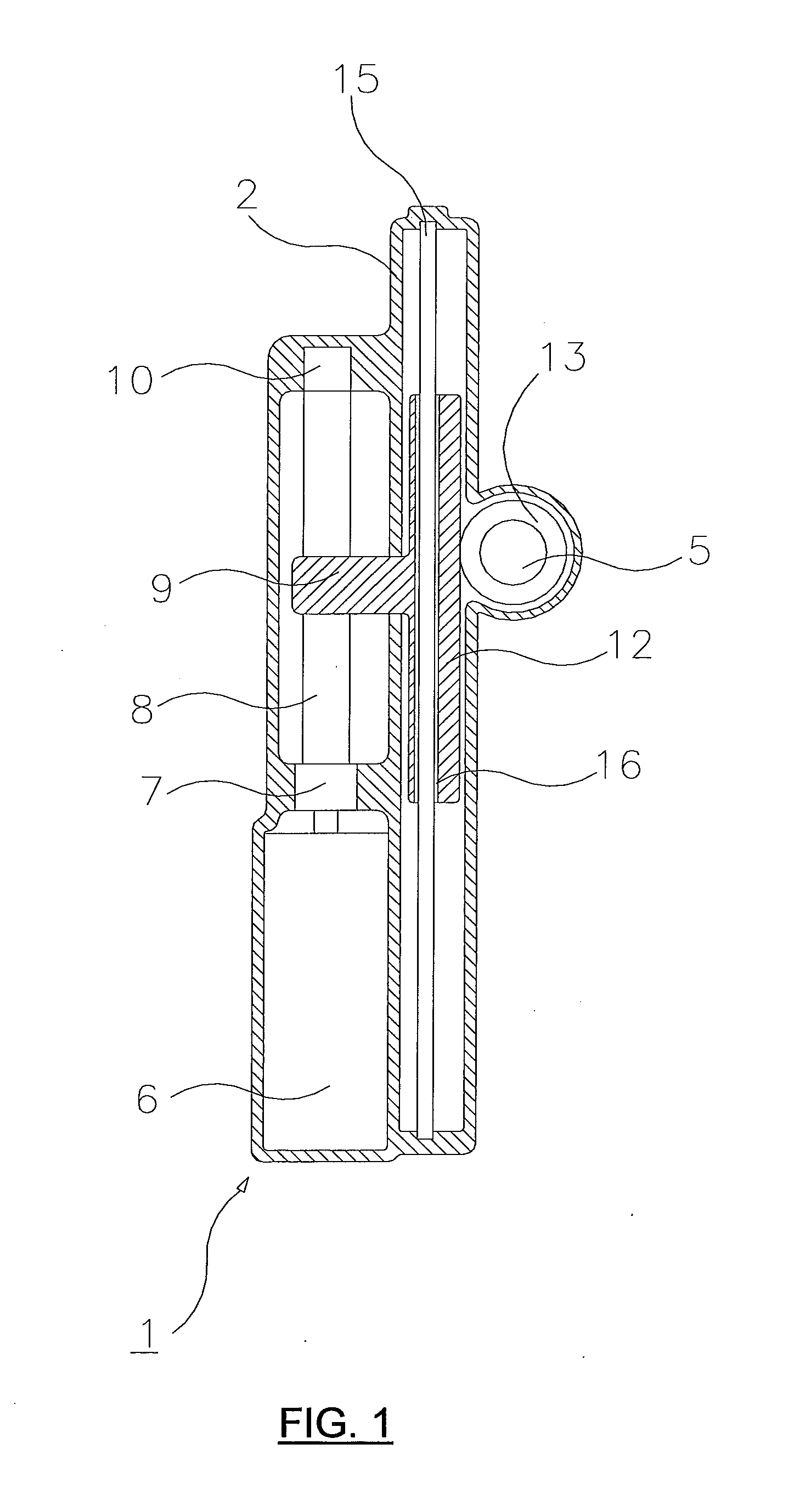

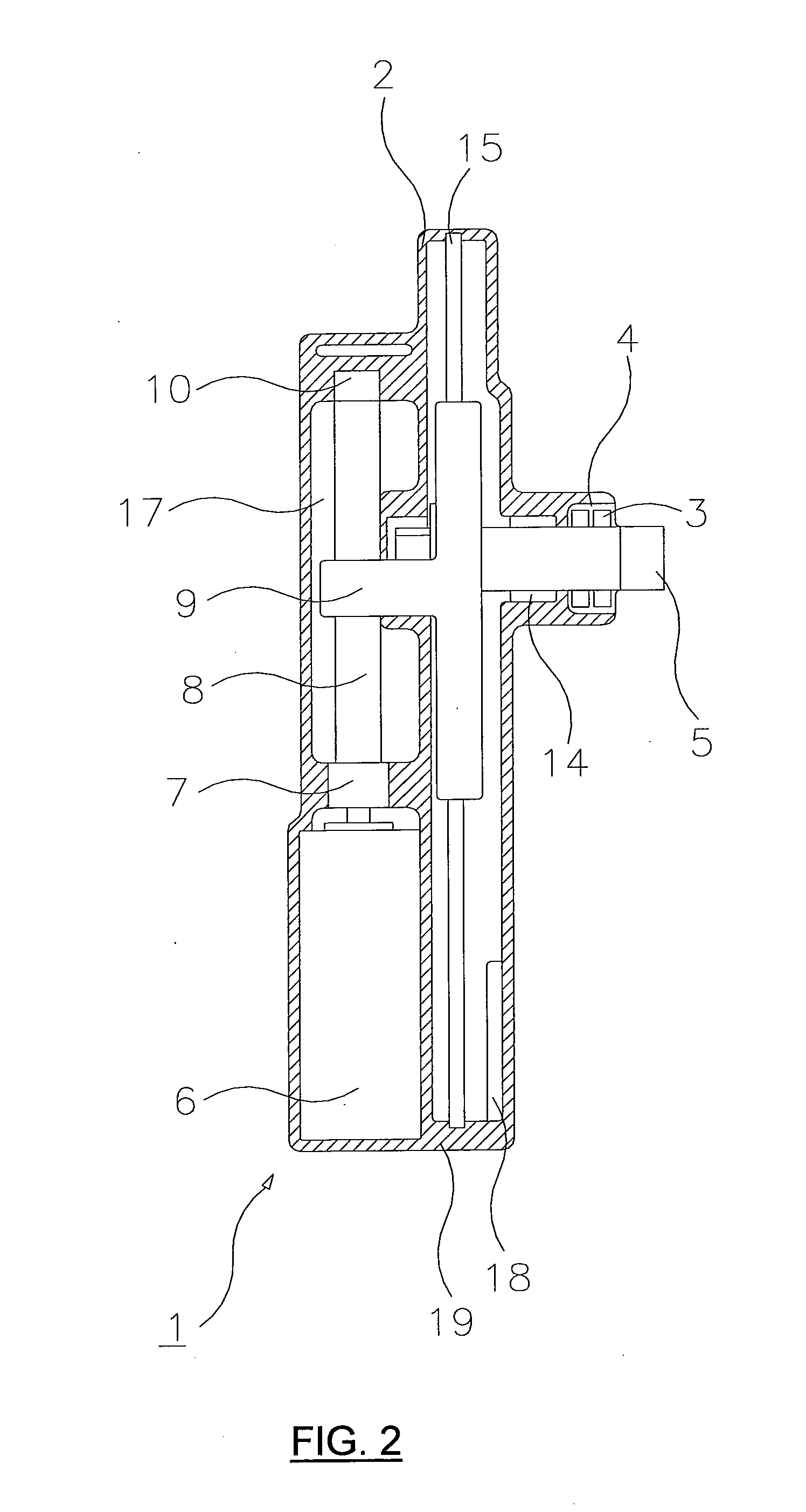

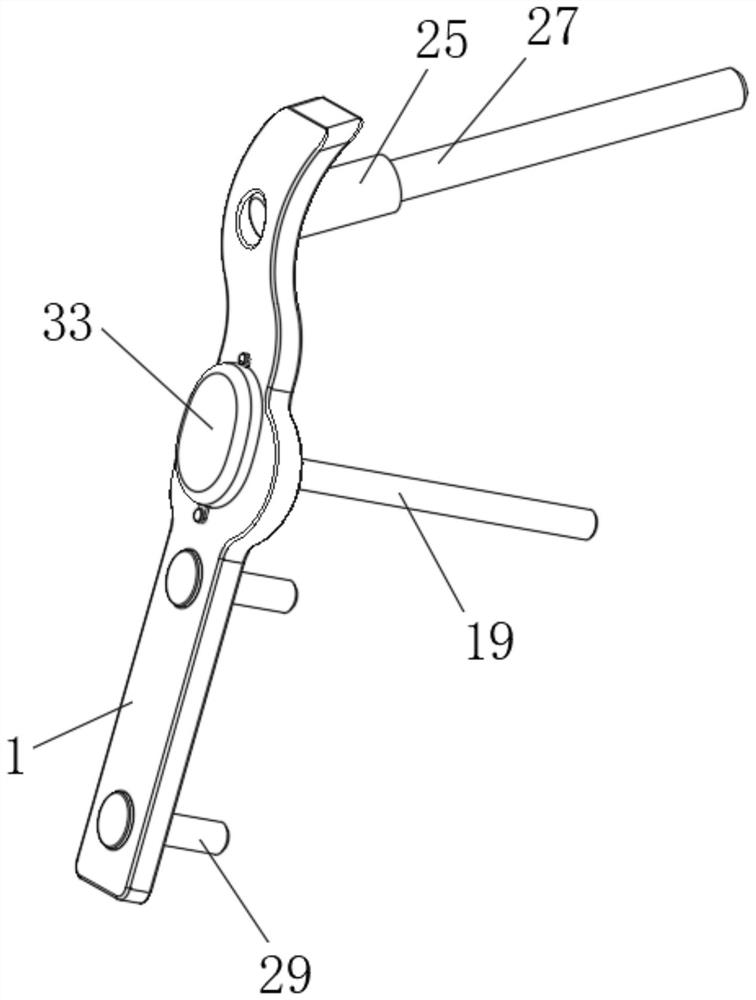

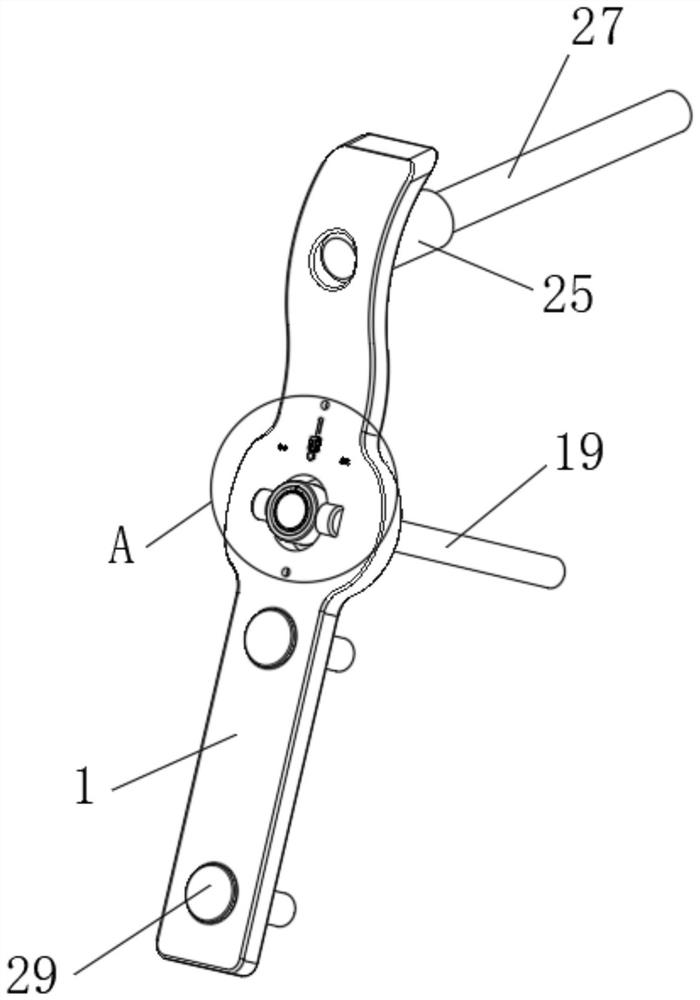

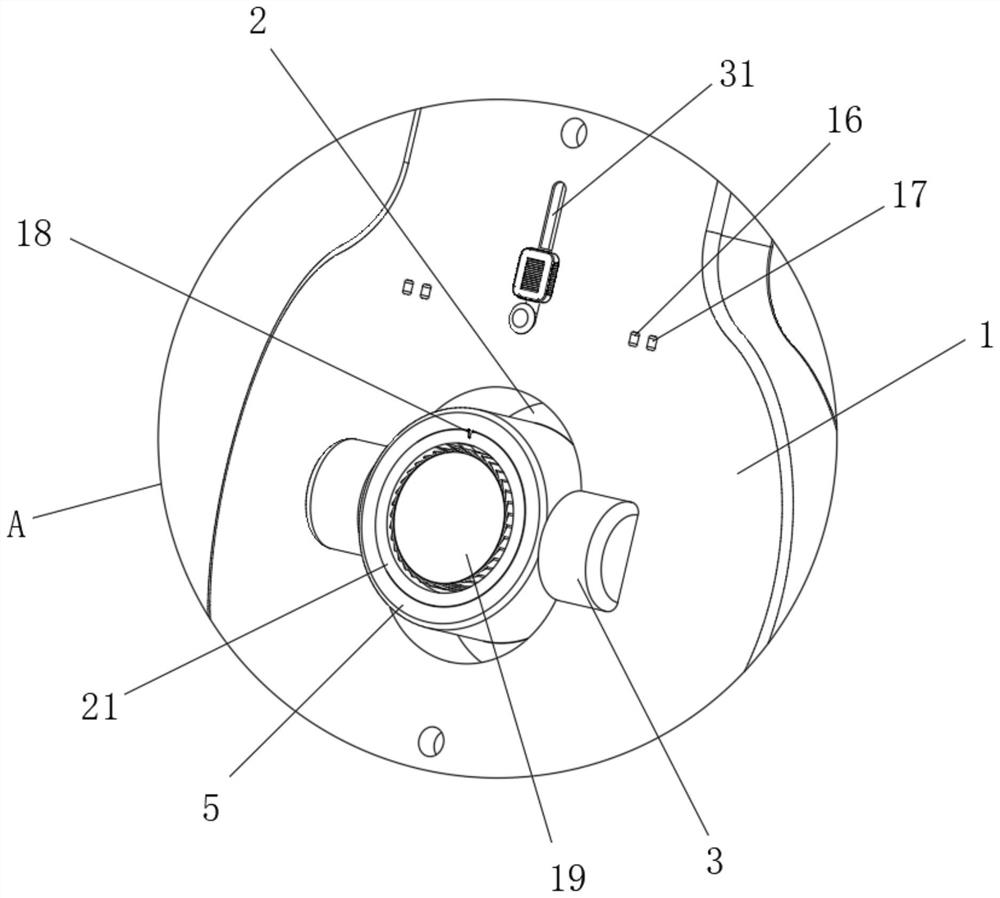

Gearbox

InactiveUS20110290057A1Vibration minimizationMinimise wearManual control with multiple controlled membersWheelchairs/patient conveyanceEngineeringActuator

A gearbox having a housing, an actuator, a leadscrew rotated by the actuator, a rack nut threadingly engaged with the leadscrew to move longitudinally as the leadscrew rotates, a toothed section that moved with the rack nut, a shaft and a gear integral with or coupled to the shaft, and arranged such that rotation of the gear causes rotation of the shaft.

Owner:CORCOST LTD

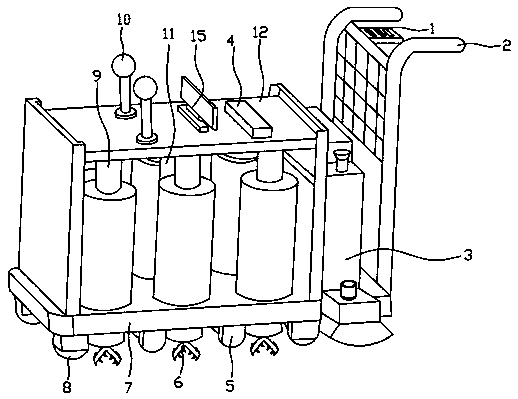

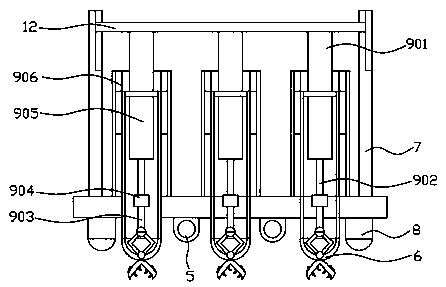

Agricultural weeding device

InactiveCN109601029AAvoid accumulationPrevent regenerationSoil-working equipmentsWeed killersAgricultural engineeringWeed

The invention discloses an agricultural weeding device. The agricultural weeding device comprises a weeding machine body, a connecting mechanism and a control mechanism, wherein the control mechanismis connected with the weeding machine body through the connecting mechanism; and the weeding machine body comprises a weeding rack, a weeding device, a cutting device and a collecting device, the weeding rack is used for carrying the connecting mechanism and the control mechanism, the weeding device is mounted on the bottom of the weeding rack and is used for removing weeds, the cutting device ismounted on the bottom of the weeding rack, is spaced from the weeding device, and is used for cutting the weeds, and the collecting device is arranged on one side of the weeding rack, and is used forcollecting and treating the weeds. The device can reduce the stress resistance and renewability of the weeds while removing the weeds, and stops weed regrowth.

Owner:金华市众鑫农业科技有限公司

Method of purifying sorbic acid

InactiveCN105198727ASimple processGood choiceCarboxylic compound separation/purificationSorbic acidImpurity

The invention discloses a production process for preparing high-purity sorbic acid by utilizing melt crystallization. The production process comprises the following steps: first introducing chilled brine into the bottom of a melt crystallizer outer jacket, facilitating the chilled brine to uniformly flow on the outer wall of the crystallizer in a falling film manner, then putting a crude sorbic acid solution into a melt crystallizer, gradually cooling the sorbic acid solution to be crystallized under the condition that the sorbic acid solution flows down in a falling-film manner on the inner wall of the crystallizer, gradually growing a uniform crystal layer on a heat exchanging surface, wherein the concentration of the crystal layer is higher than that of a mixture solution, and gradually gathering impurities into the mixture solution; partially melting the crystal layer by adjusting the temperature of hot water via a heat exchanger, melting and eliminating partial low-melting-point substances mingled in the crystal layer, and further purifying crystal. The method is simple in process, equipment is compact in structure, a falling film form is adopted, the energy is reduced, and meanwhile the cost and equipment investment are reduced; the purity of a product produced by utilizing the melt crystallizer is high.

Owner:张勇

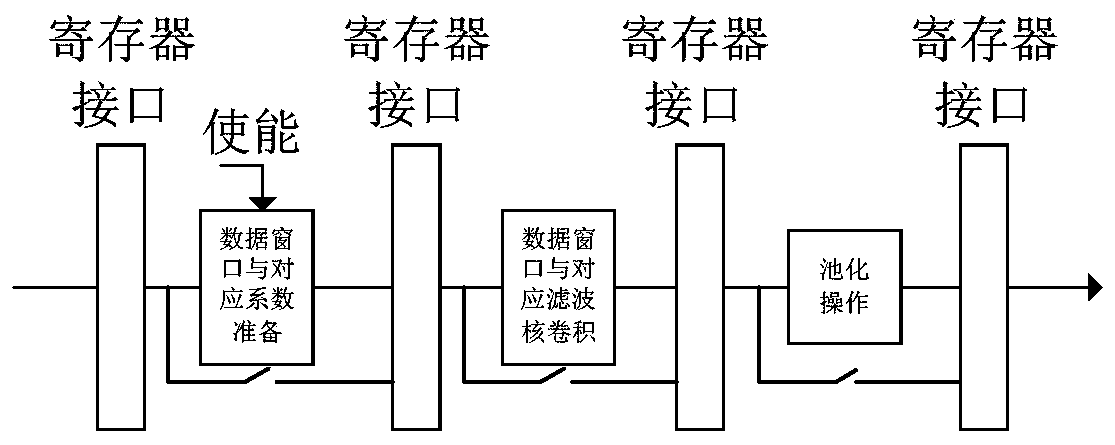

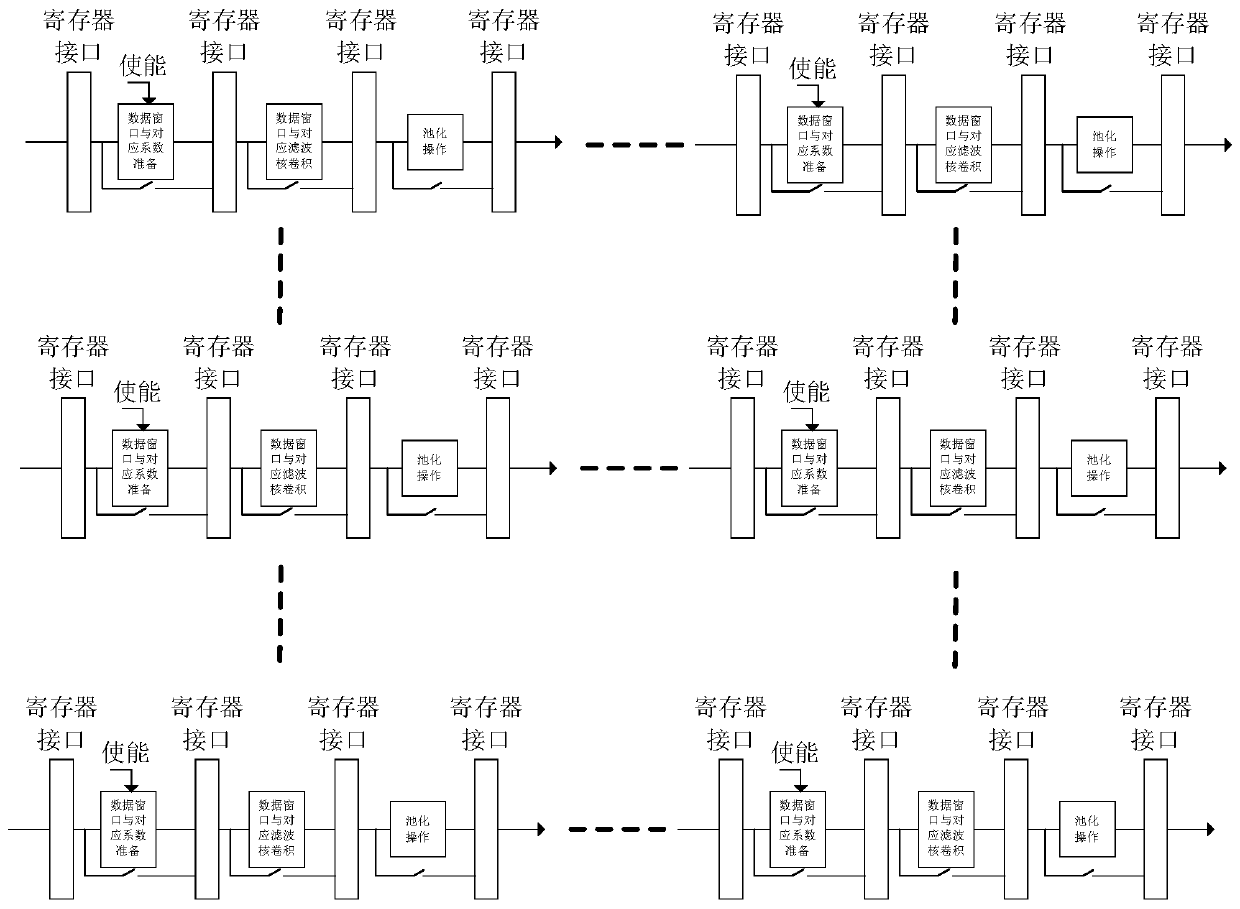

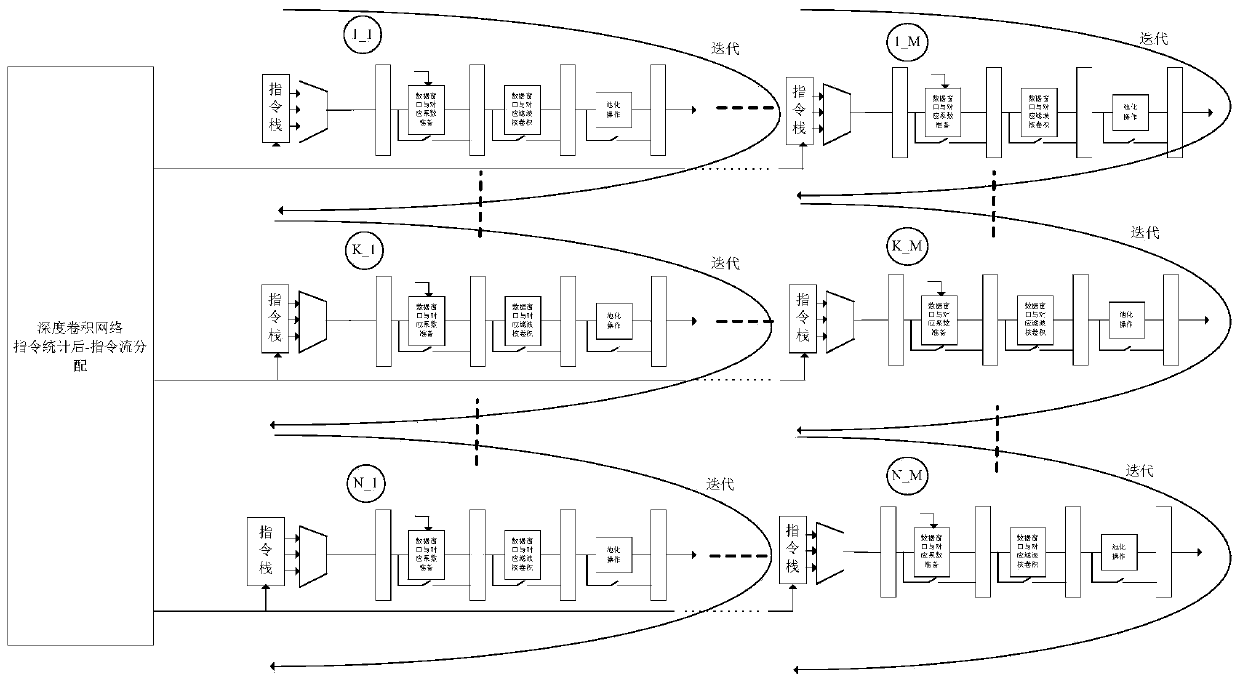

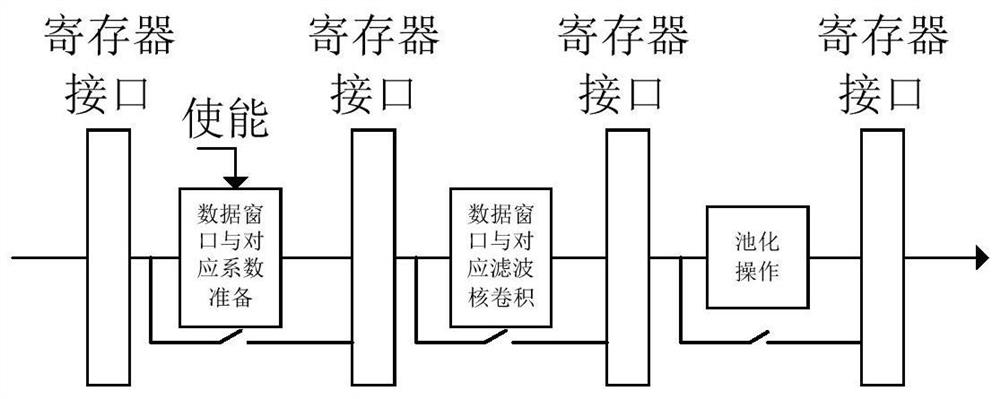

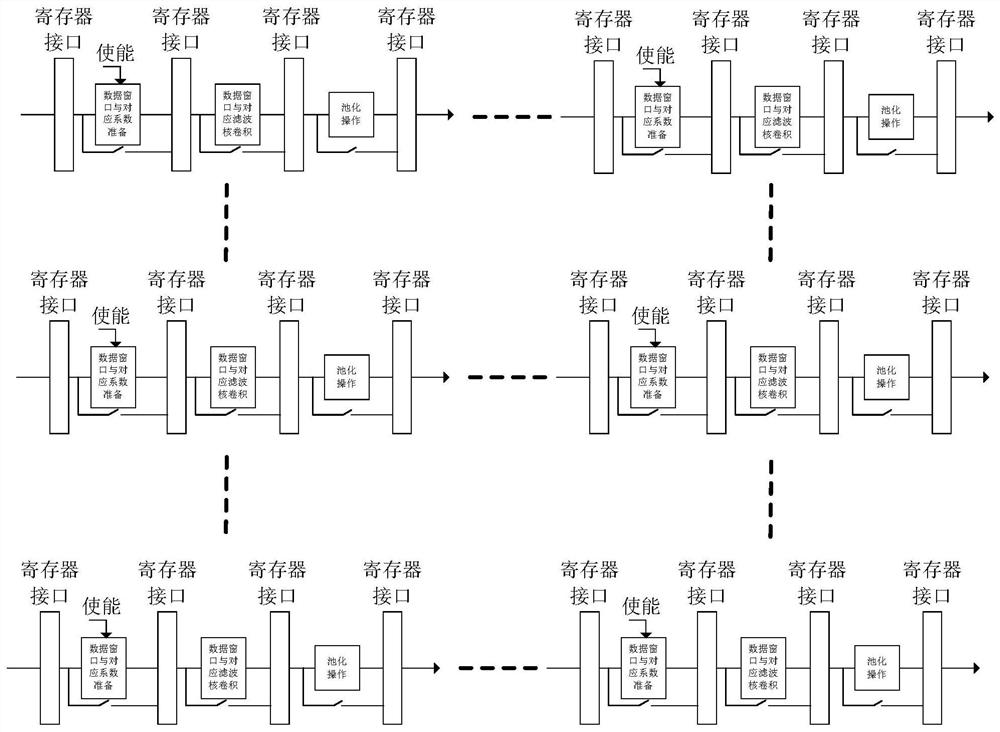

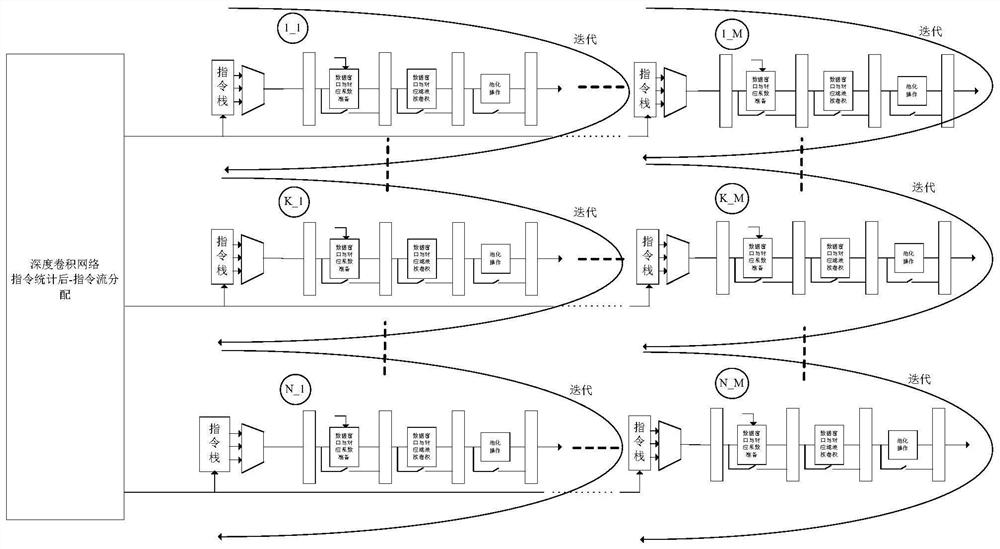

Deep learning network application distribution self-assembly instruction processor core, processor, circuit and processing method

ActiveCN110516800AConfigurableReduce usageNeural architecturesPhysical realisationProcessor registerNetwork architecture

The invention discloses a deep learning network application distribution self-assembly instruction processor core, a processor, a circuit and a processing method. The processor core comprises four register interface modules, and a preparation module, a convolution operation module and a pooling operation module are sequentially arranged between every two register interface modules; the processor comprises an instruction statistical distribution module which is configured to count deep convolutional network instructions and distribute instruction streams; the instruction statistics and distribution module is connected with the processor cores through the instruction stack module. And the instruction stack module is configured to receive and store the instruction streams allocated by the instruction statistical allocation module, perform acceleration operation of multiple instruction streams according to the stored instruction streams, control the processor core to form neural convolutional network architectures with different depths, and perform calculation processing.

Owner:SHANDONG NORMAL UNIV

Method for purifying aluminum oxide

InactiveCN108622923AAchieve separationAchieve purificationChemical industryAluminates/aluminium-oxide/aluminium-hydroxide purificationThermal waterWater temperature

The invention discloses a production process for preparing high-purity aluminum oxide by utilizing melt crystallization, and the production process comprises the following steps: introducing frozen saline water into the bottom of an outer jacket of a melting crystallizer, enabling the frozen saline water to uniformly flow on the outer wall of the crystallizer in the form of a falling film; addinga rough aluminum oxide solution into the melting crystallizer, flowing down the aluminum oxide solution on the inner wall of the crystallizer in the form of the falling film, cooling step by step to crystallize, growing out a uniform crystal layer on a heat exchange surface step by step, enabling concentration of the crystal layer to be higher than that of a mixture solution, enriching impuritiesinto the mixture solution step by step; regulating the hot water temperature through a heat exchanger for performing partial melting operation on the crystal layer, enabling low-melting-point impurities in the crystal layer to partly melt and remove, thereby further purifying the crystal. According to the method disclosed by the invention, the process is simple, the equipment structure is compact,the falling film form is adopted, energy is reduced, cost and equipment investment are reduced; and a product produced by the melting crystallizer is high in purity.

Owner:NANTONG DISONG TEXTILE CO LTD

Method for purifying sorbic acid

InactiveCN105949050ASimple processGood choiceCarboxylic compound separation/purificationSaline waterImpurity

The invention discloses a production technology for preparing high-purity sorbic acid by utilizing melt crystallization. The production technology comprises the following steps: firstly, filling frozen saline water into the bottom of an outer jacket of a melt crystallizer, wherein the frozen saline water evenly flows in a falling film manner on the outer wall of the crystallizer; after that, putting a coarse sorbic acid solution into the melt crystallizer, wherein the sorbic acid solution flows down in a falling film manner on the inner wall of the crystallizer so as to be gradually cooled and further crystallized; enabling a uniform crystal layer to gradually grow on the heat exchange surface, wherein the concentration of the crystal layer is higher than that of a mixture solution, and gradually enabling impurities to be enriched in the mixture solution; then, adjusting the temperature of hot water by using a heat exchanger, carrying out partial melting operation on the crystal layer so as to melt and remove low-melting-point impurities mixed in the crystal layer, and further purifying crystal. The method is simple in technology and compact in equipment structure, adopts a falling film form so as to reduce energy, and can reduce cost and equipment investment; the product produced by using the melt crystallizer is high in purity.

Owner:南通中兴多元复合钢管有限公司

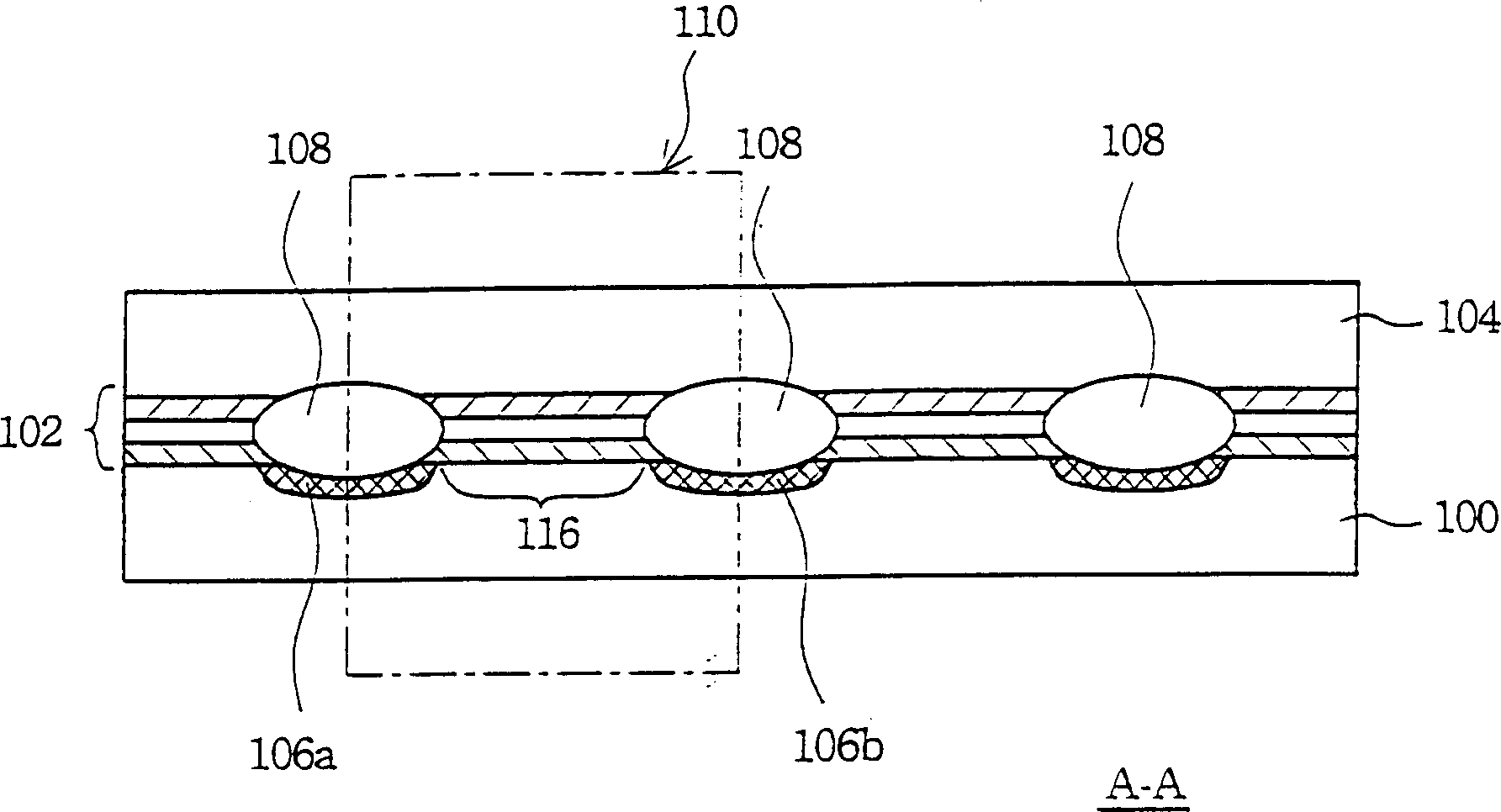

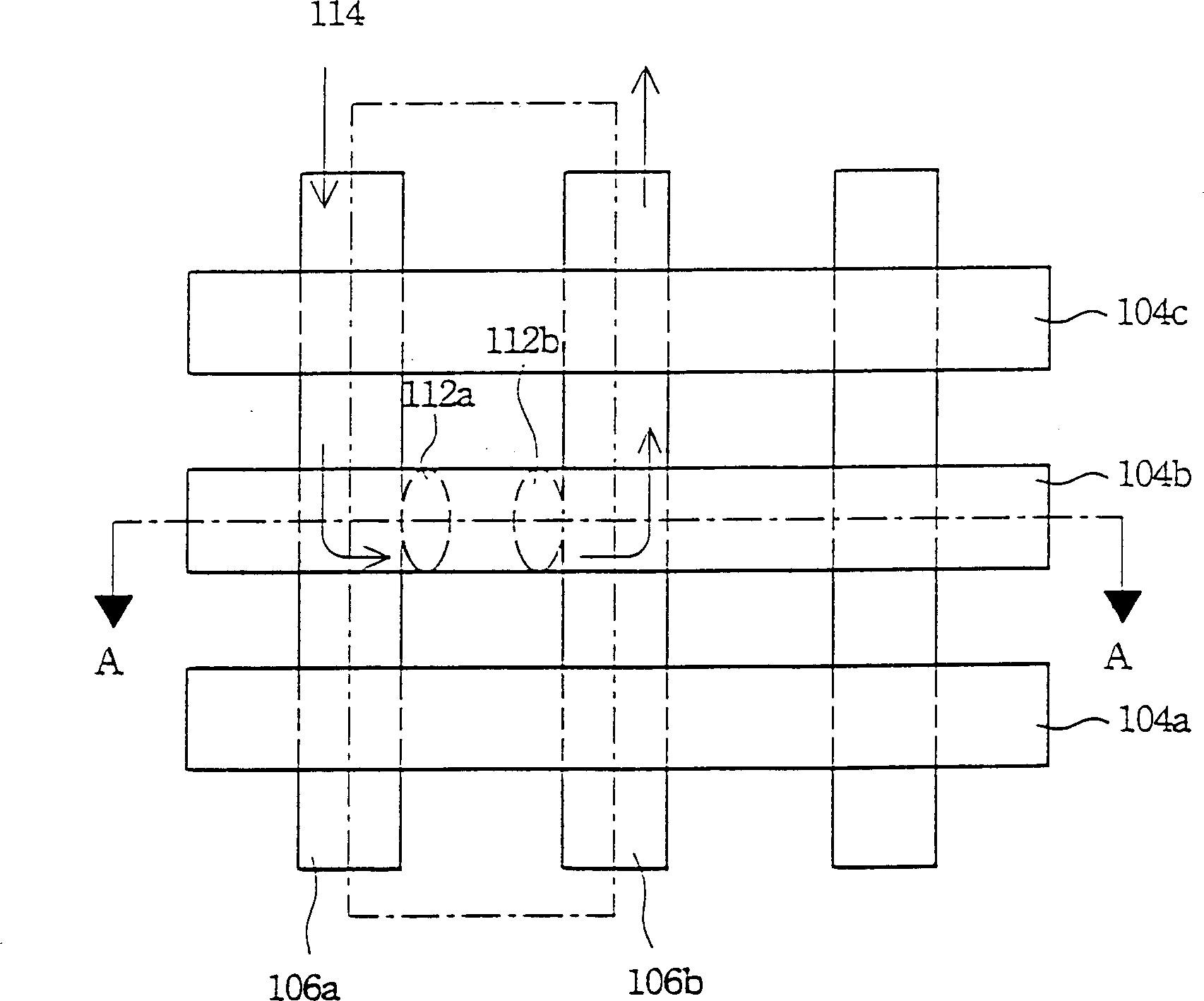

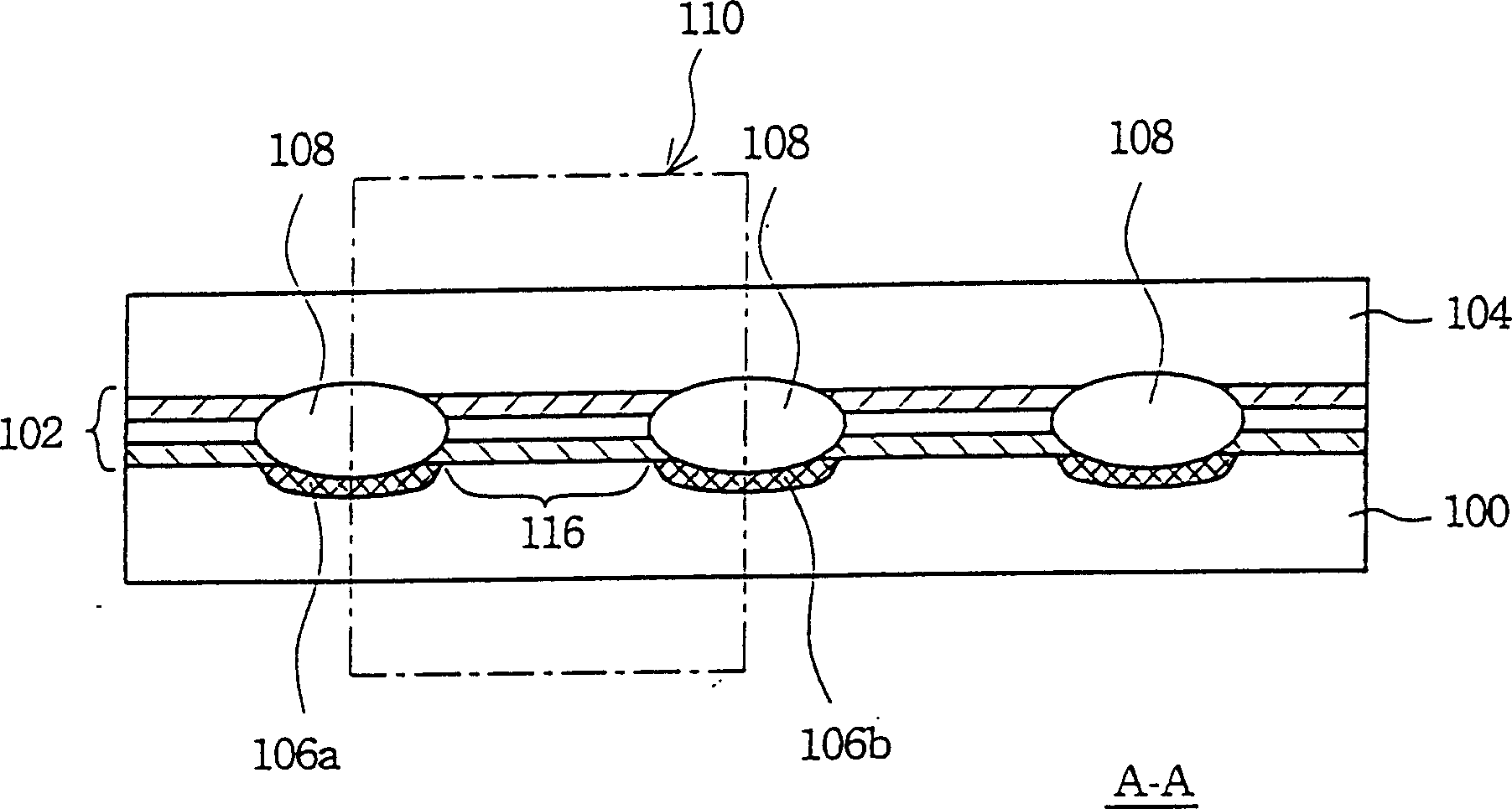

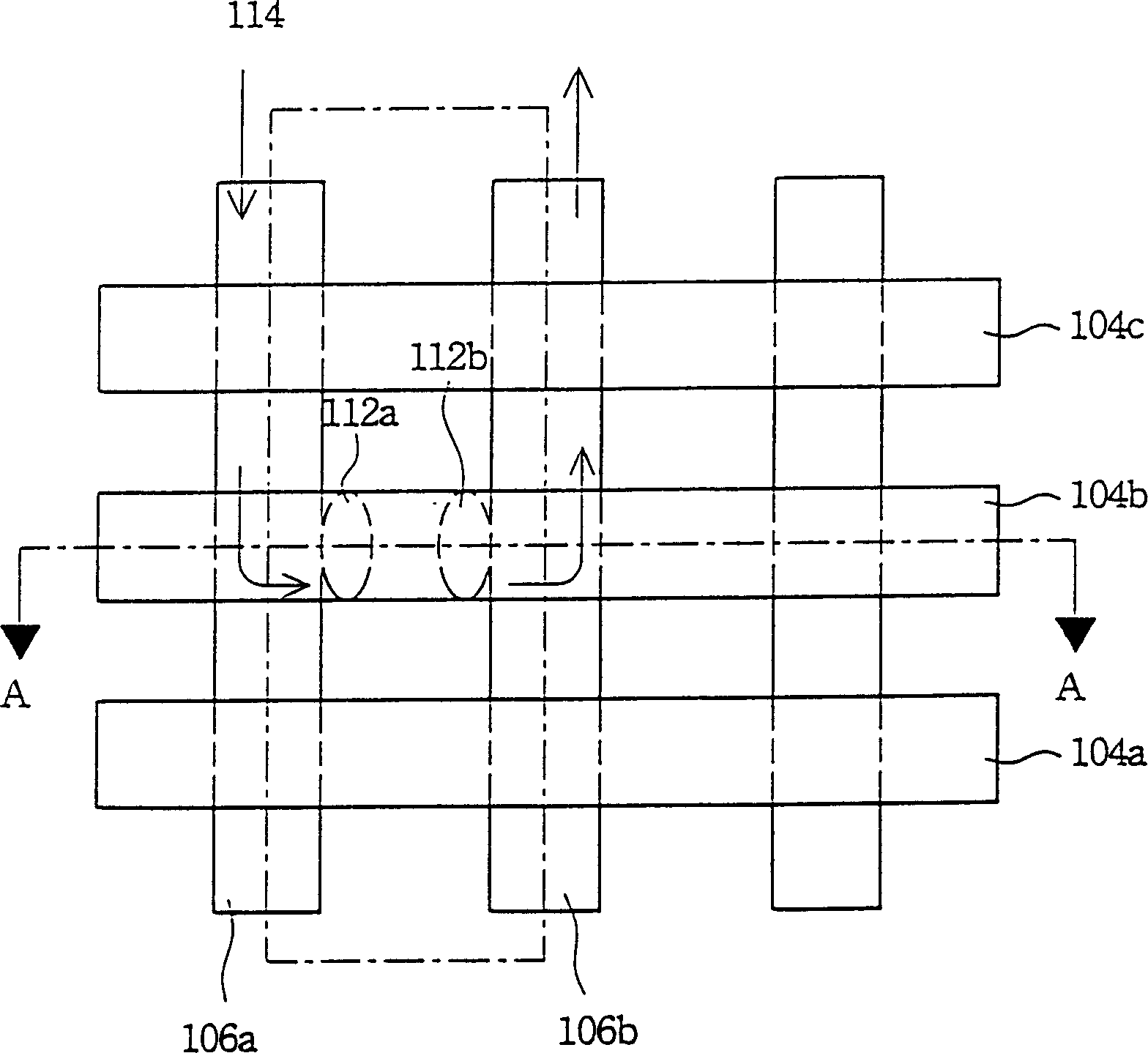

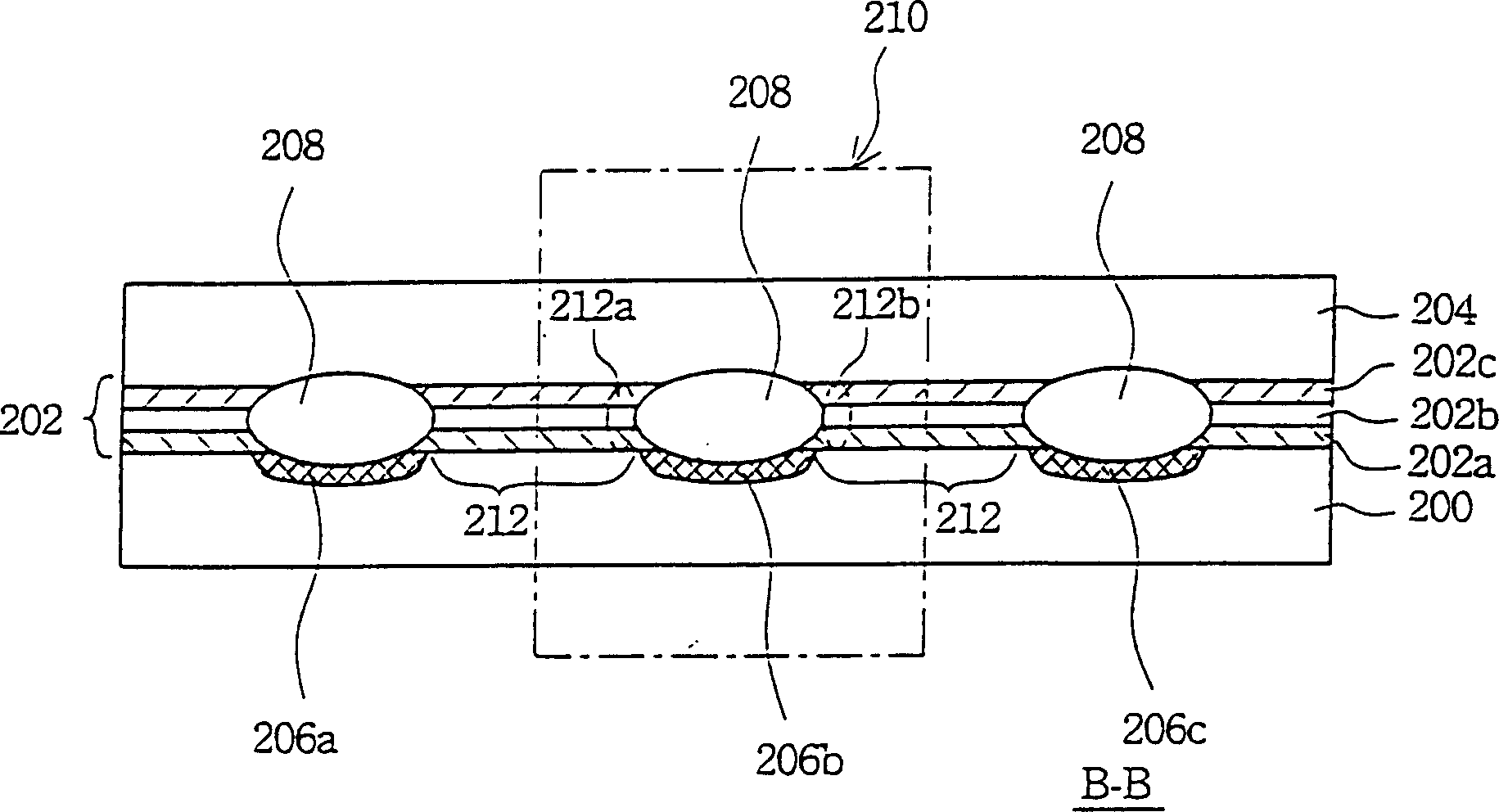

Operation method of fast erasable and rewritable memory with symmetrical double-channel

InactiveCN1400601AIncrease the number of operationsImprove reading speedSemiconductor/solid-state device manufacturingDigital storageComputer scienceVoltage

There is a manipulating method for flash memory with a symmetrical dual channel, it at least includes: at first, it writes procedure into quick erasable memory, makes the charge locate at both side sof ONO layer in the second wire in order to form the symmetrical dual channel structure, and accomplishes writing operation of one bit, then it transmits the selective voltage to the first and the third bit with in order to select the second bit wire for symmetrical structure. Following the second bit wire should be grounded. Then the reading voltage is transmitted to the second letter wire, at the same time it collects reading current, and the current is the total of current which pass through the symmetrical dual channel, so the speed of reading of flash memory is advanced.

Owner:MACRONIX INT CO LTD

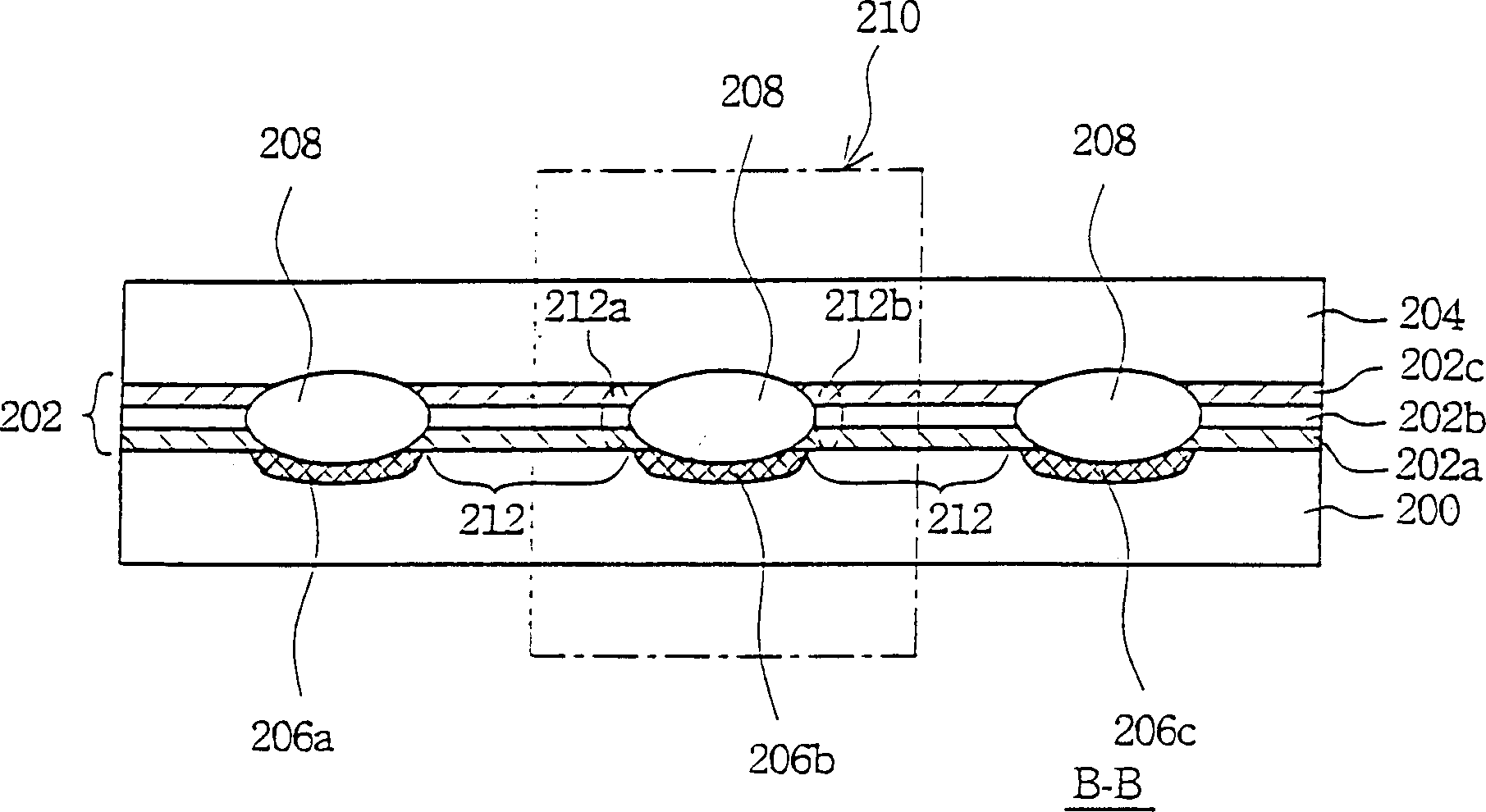

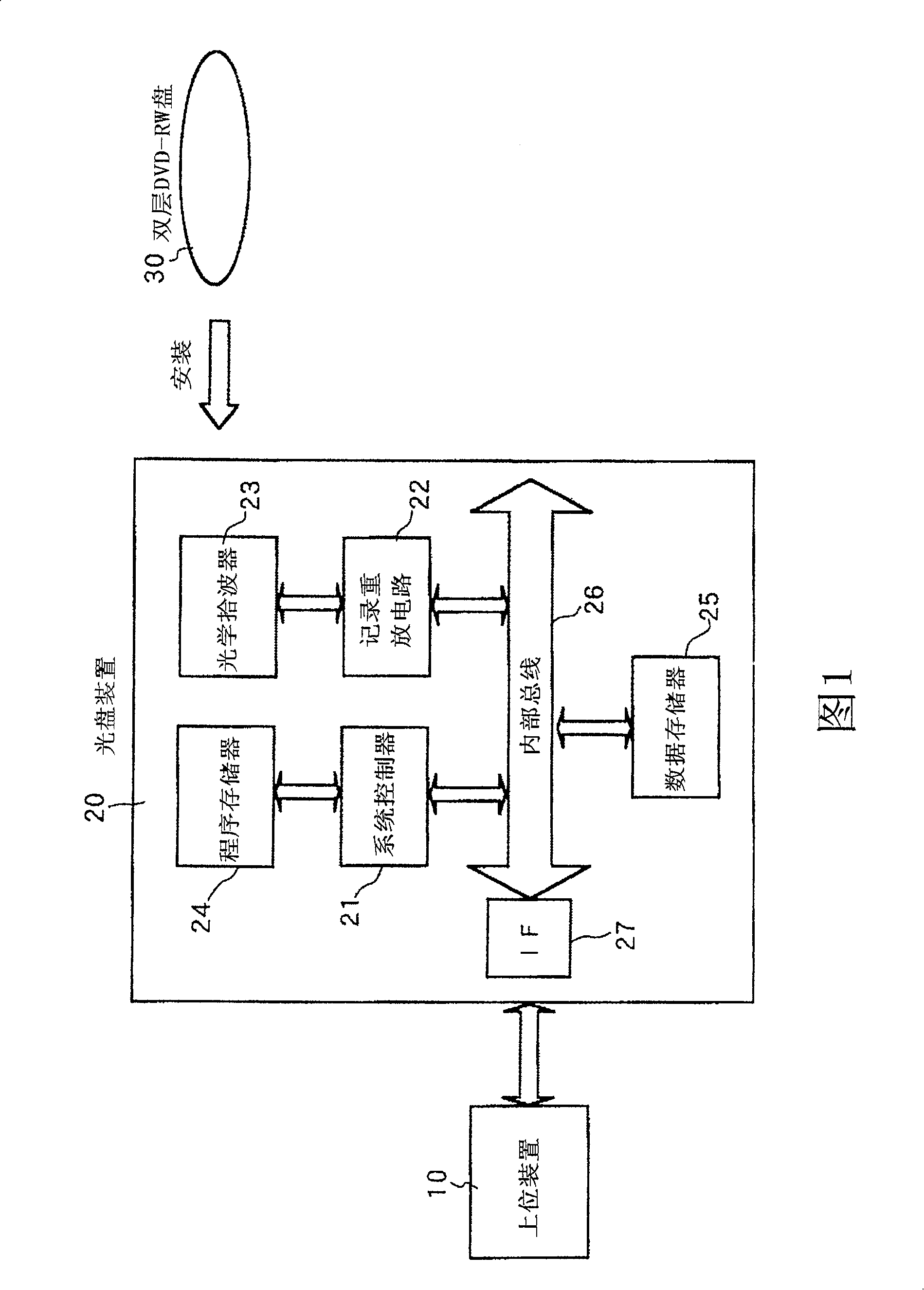

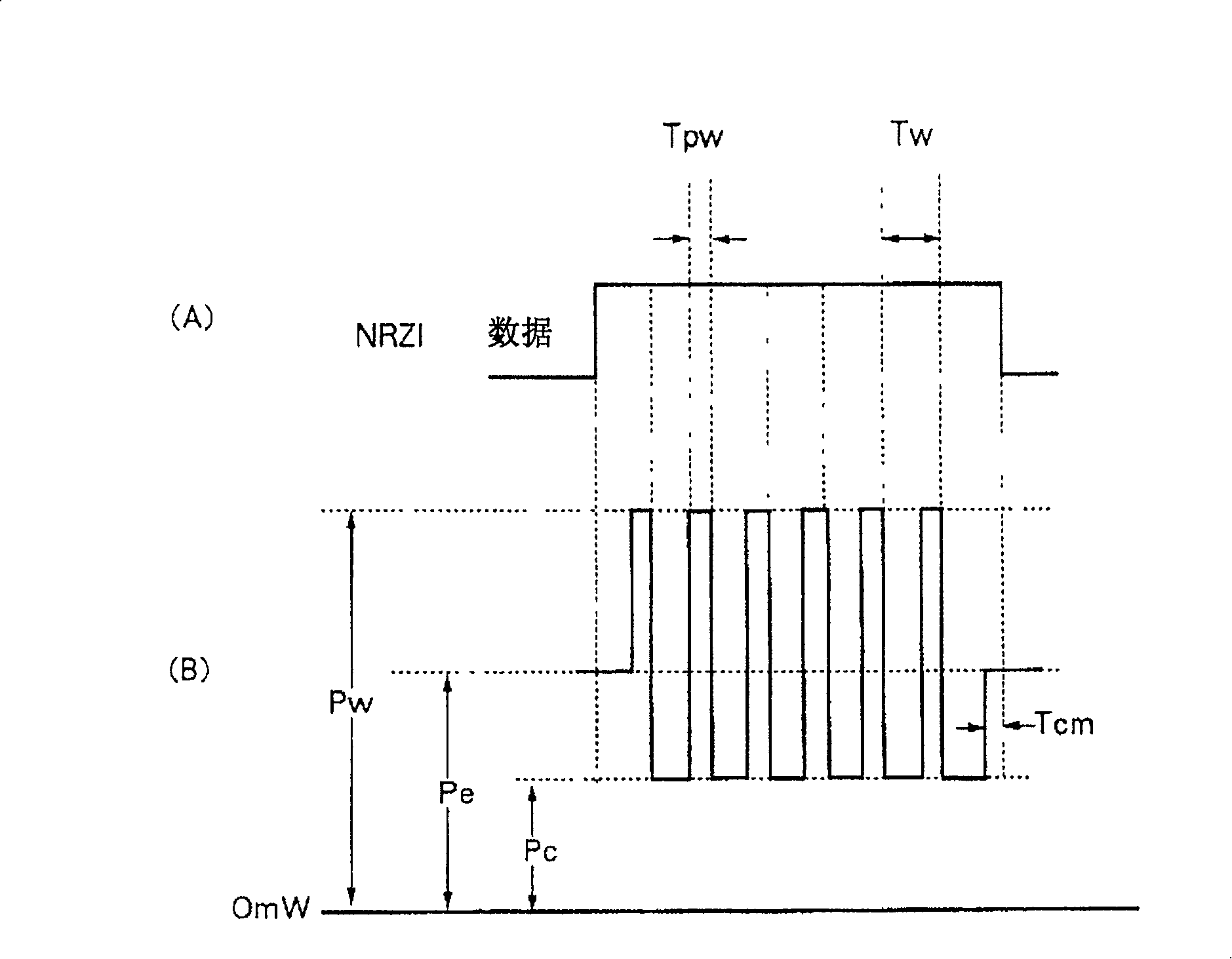

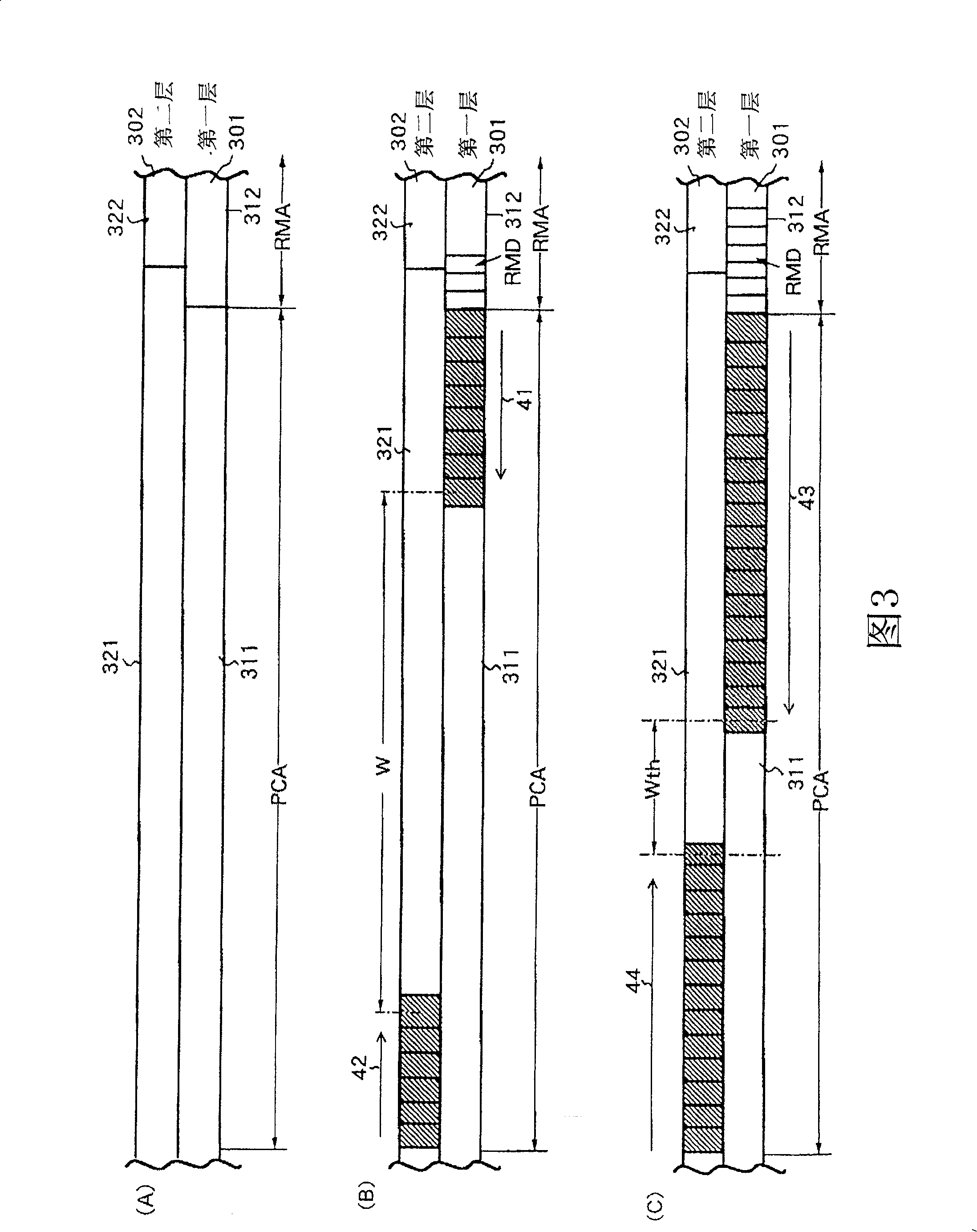

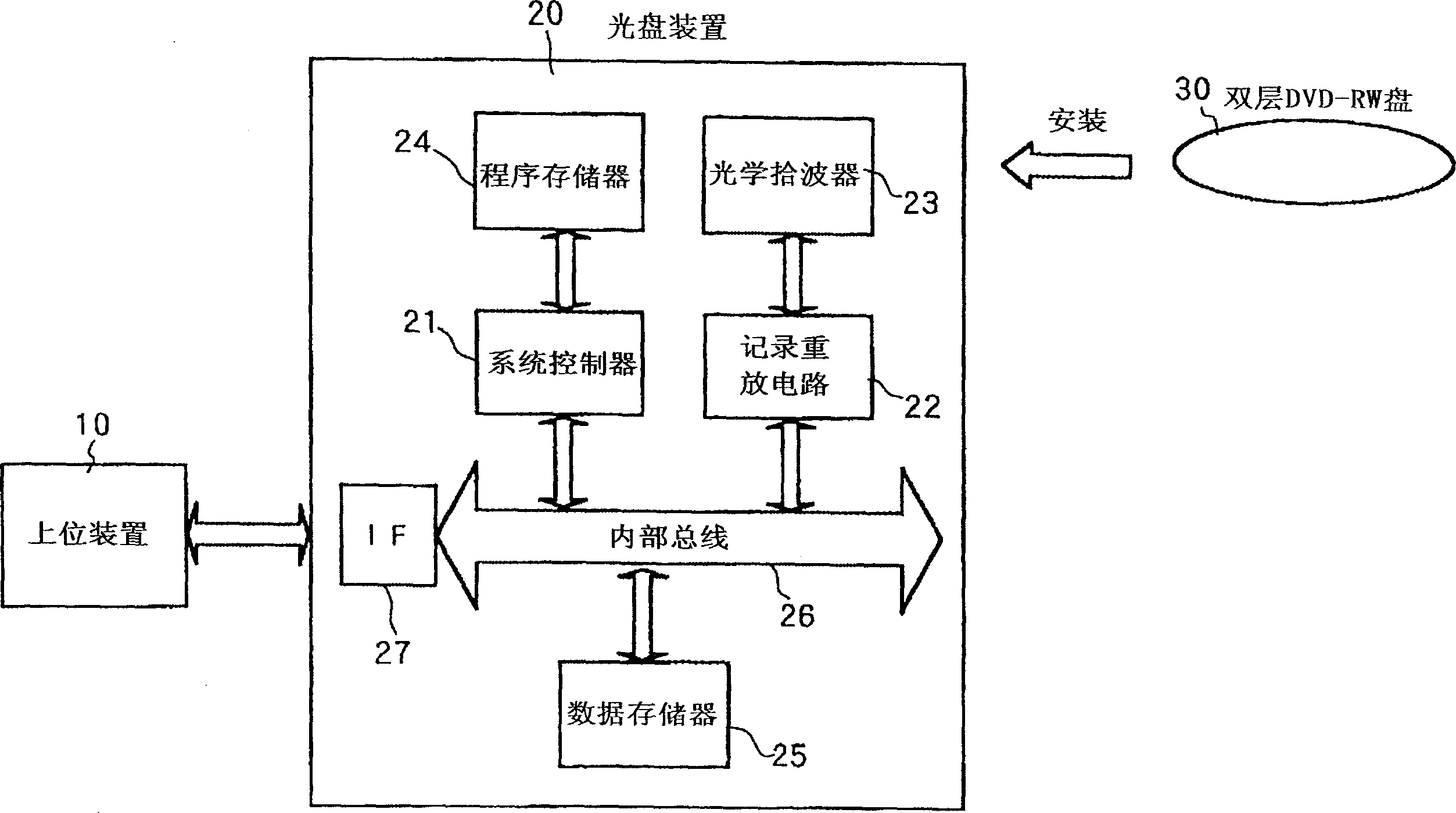

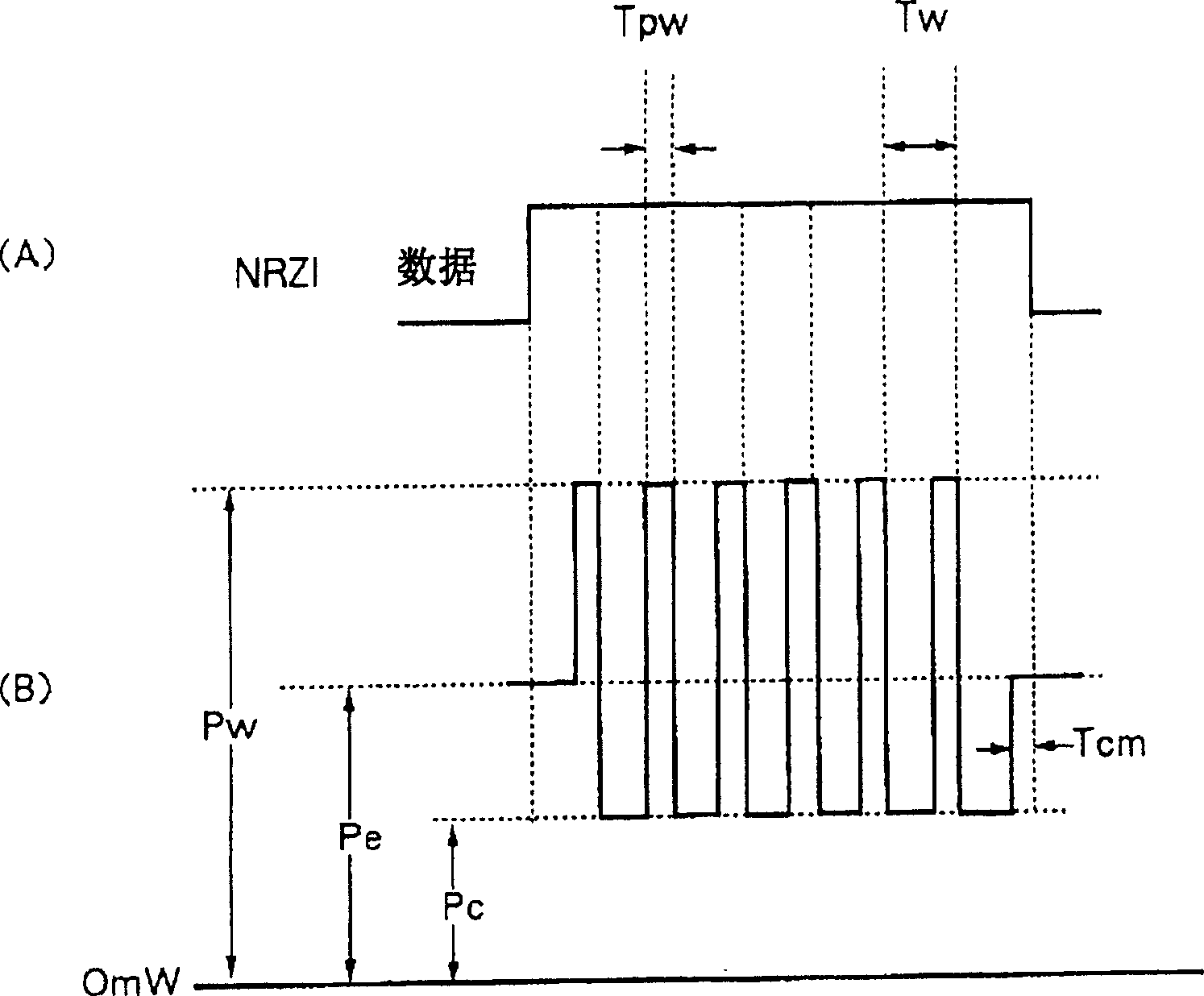

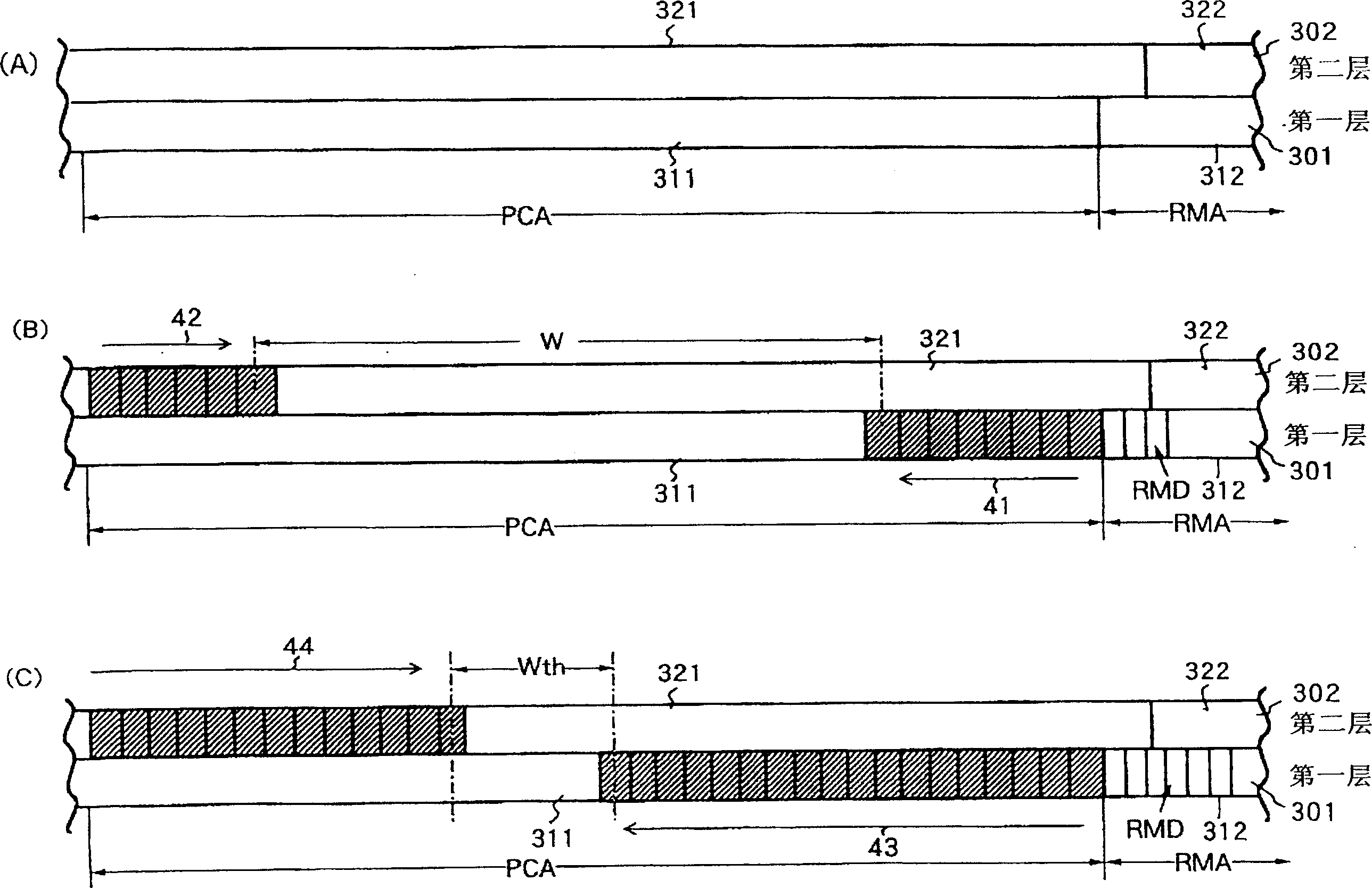

Optical information recording apparatus

ActiveCN100405472CReduce deteriorationIncrease the number of operationsRecording verificationRecord information storageComputer scienceOptical disc

Owner:JVC KENWOOD CORP

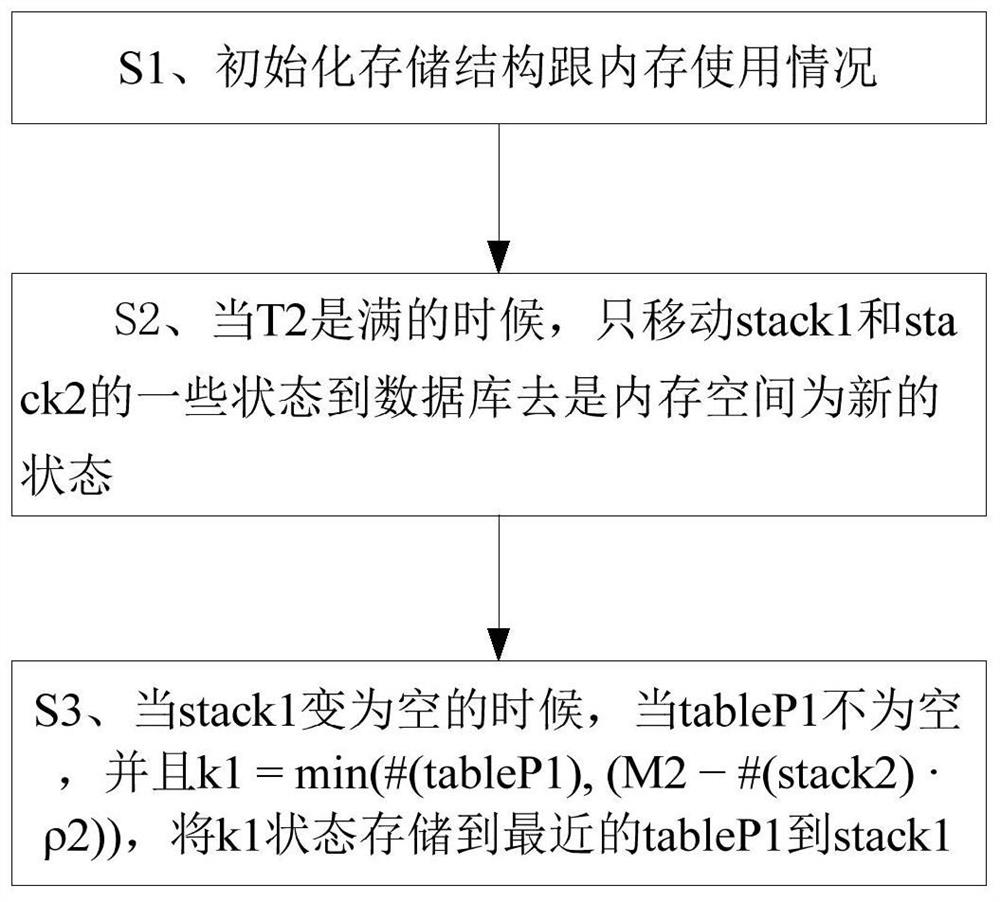

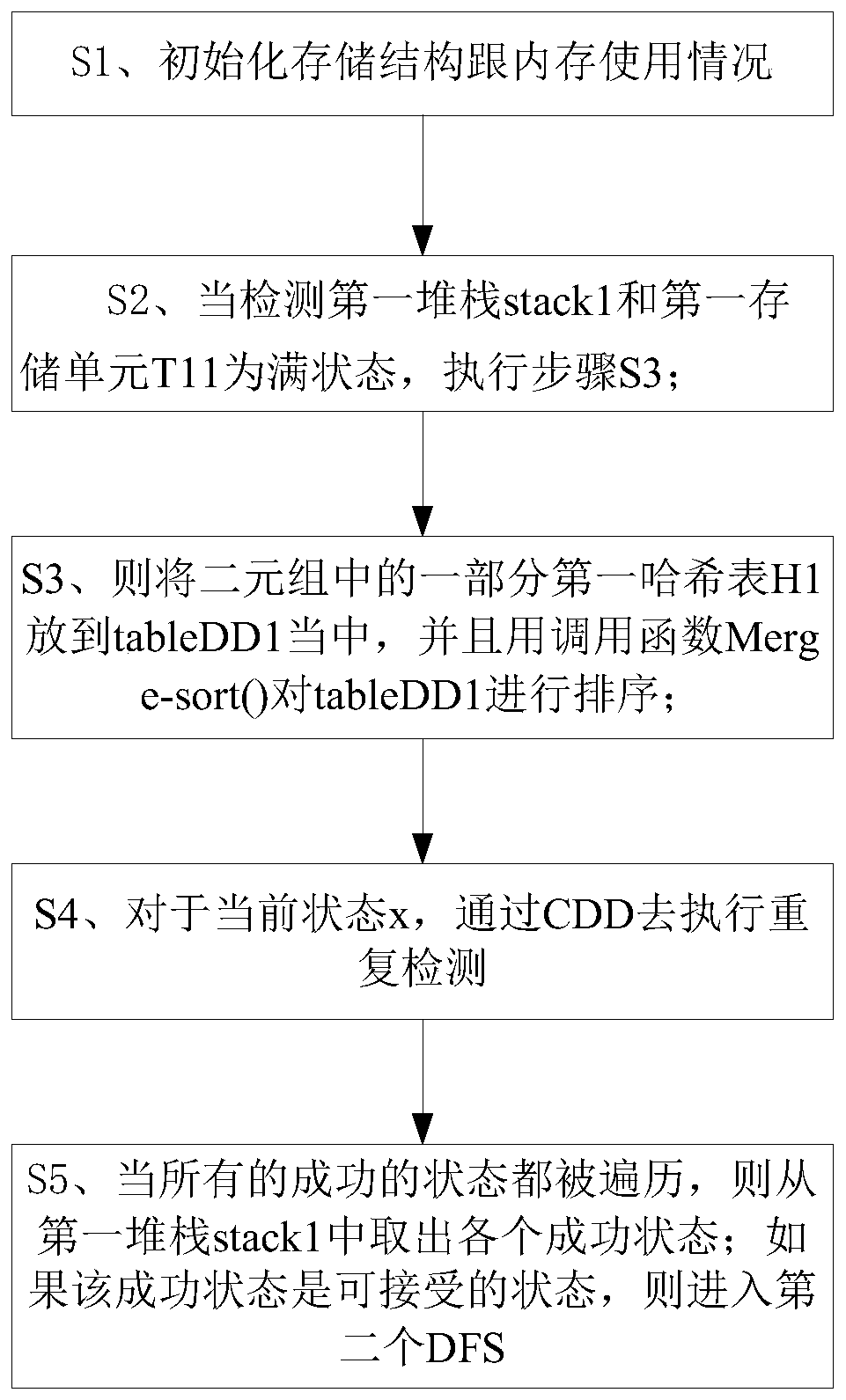

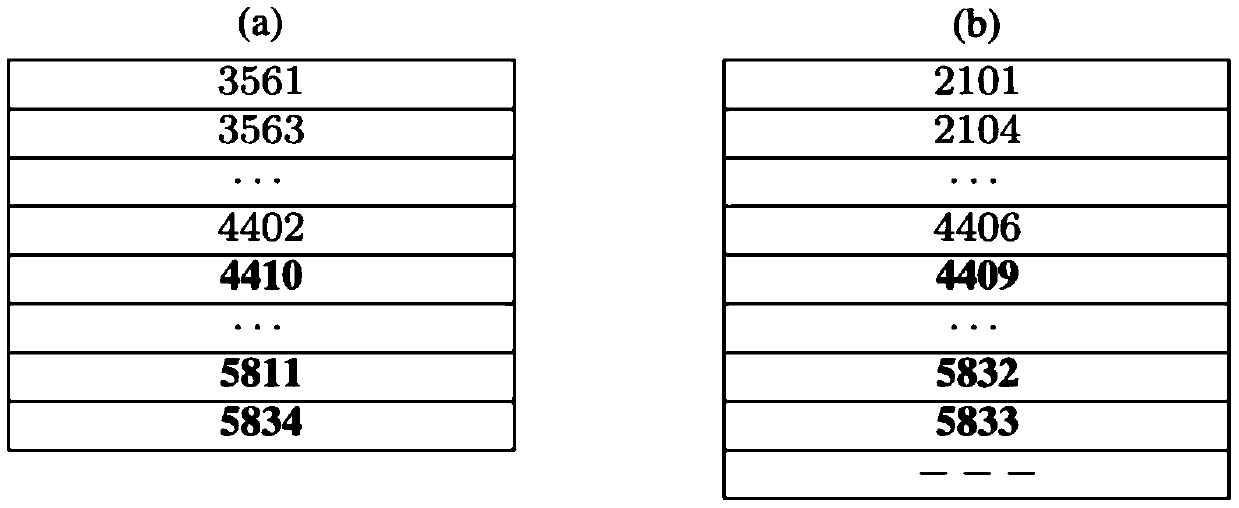

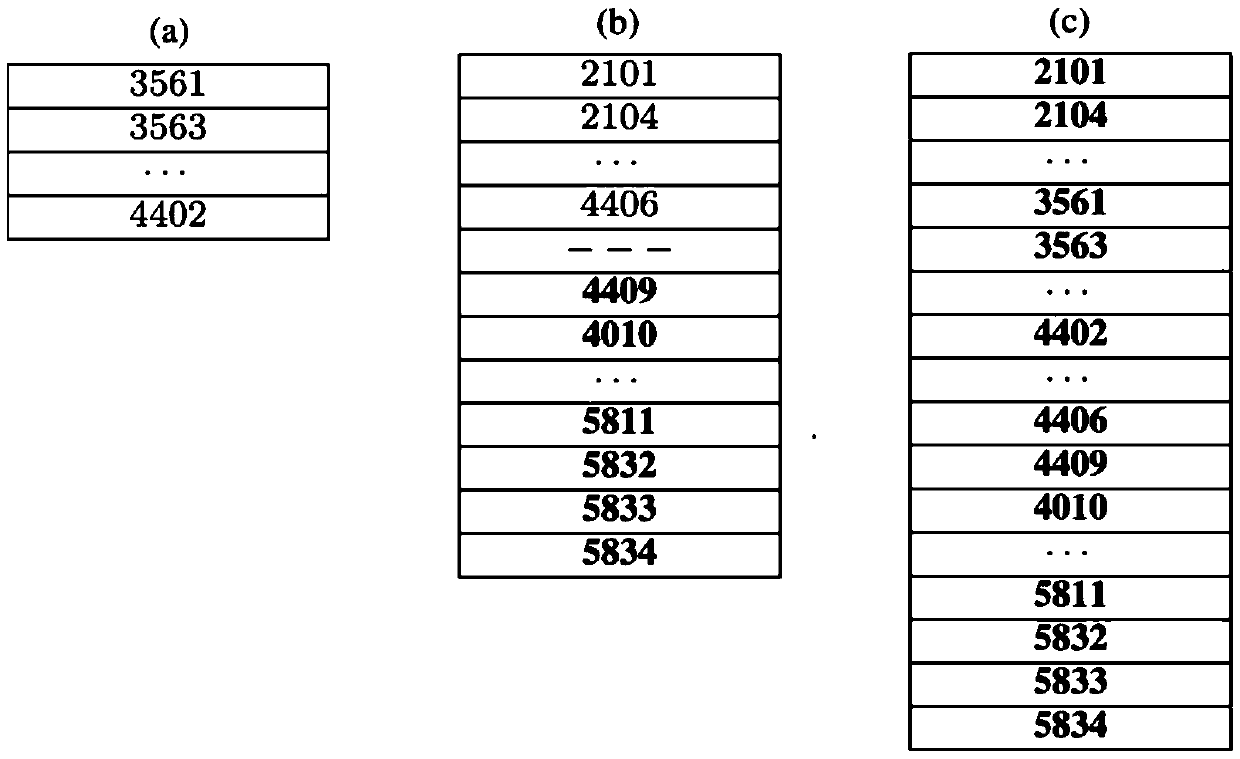

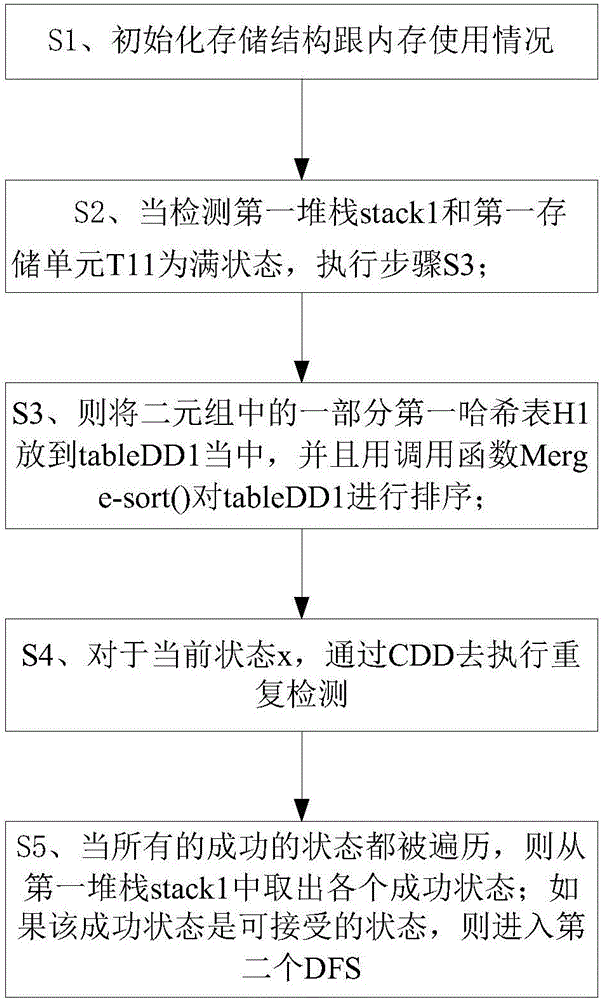

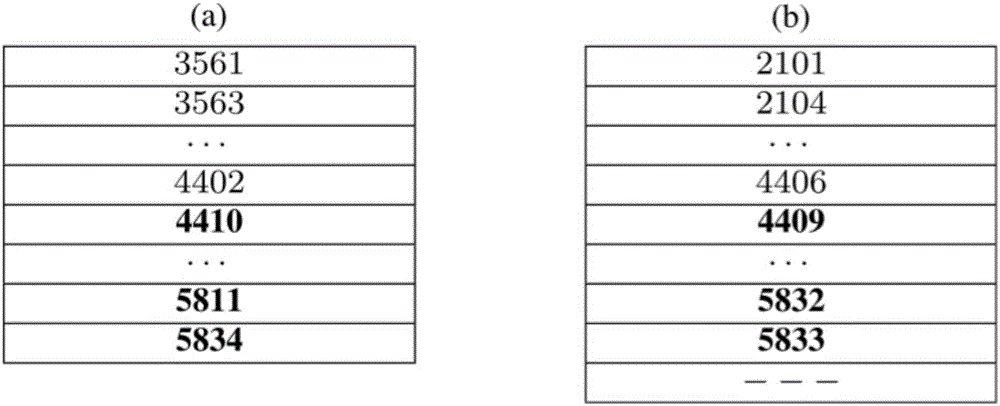

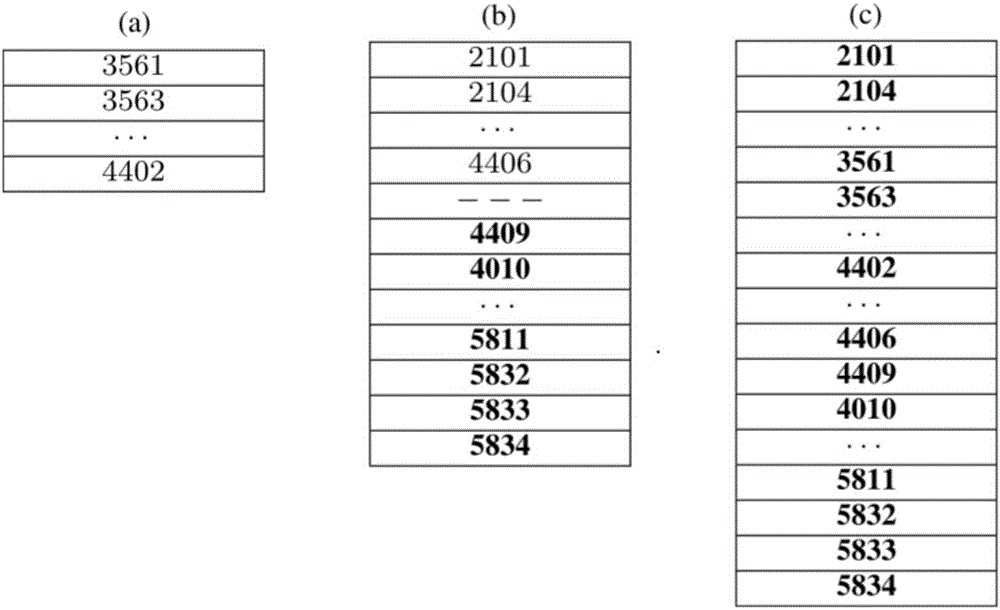

An Efficient Large-Scale System LTL Model Checking Method for De-memory Jittering

InactiveCN106371765BReduce complexityIncrease the number of operationsInput/output to record carriersThrashingMemory cell

The invention discloses a method for removing memory thrashing through the efficient LTL ((Linear Temporal Logic) model detection of a large-scale system. A LHS (Linear Hash Storage) algorithm is adopted to mainly aim at quickly finding a Hash value stored in a Hash table in a disk; no matter whether the classification of the Hash table in the memory is empty or not, the Hash table can be stored in an external memory and is processed by a new technology after being stored in the external memory, and the complexity of I / O is a linear size which is the same with the Hash table; and a CDD (Cached Duplicate Detection) technology permits a duplicate in the memory to be detected through effective access, duplicate detection complexity can be lowered through the LHS and the CDD, the plan of DPM (Dynamic Path Management) enables two nested depth-first stacks to dynamically share a memory cell, and the memory thrashing problem can be solved through the effective management of the stack and the state, wherein the memory thrashing means that the frequent movement of the state in the memory may obviously increase I / O operation frequencies so as to lower the efficiency of the algorithm.

Owner:CHENGDU KEHONGDA TECH

Method for purifying sorbic acid

InactiveCN106699547ASimple processGood choiceCarboxylic compound separation/purificationSalt waterSorbic acid

The invention discloses a production technology for preparing high-purity sorbic acid by melt crystallization. The production technology comprises the following steps of firstly, sending freezing salt water into the bottom part of an outer jacket of a melt crystallization device, enabling the freezing salt water to uniformly flow along the outer wall of the crystallization device in a falling film way, feeding a crude sorbic acid solution into the melt crystallization device, enabling the sorbic acid solution to flow down along the inner wall of the crystallization device in the falling film way, gradually cooling and crystallizing, gradually growing a uniform crystal layer on the heat exchange surface, enabling the concentration of the crystal layer to be higher than the concentration of mixture solution, and enabling impurities to gradually enrich into the mixture solution; then, melting one part of crystal layer by adjusting the hot water temperature through a heat exchanger, and melting and removing the impurities with low melting point in the crystal layer, so as to further purify crystals. The production technology has the advantages that the method and technology are simple, the equipment structure is compact, the falling film type is adopted, the energy is decreased, and the cost and equipment investment are reduced at same time; the purity of a product produced by the melt crystallization device is high.

Owner:于银强

Method for purifying sorbic acid

InactiveCN106946695ASimple processGood choiceCarboxylic compound separation/purificationImpuritySorbic acid

The invention discloses a production method for preparing highly pure sorbic acid by using melt crystallization. The method comprises the following steps: introducing frozen brine to the bottom of the outer jacket of a melting crystallizer, allowing the frozen brine to uniformly flow on the outer wall of the crystallizer in a falling film manner, adding a crude sorbic acid solution into the melting crystallizer, allowing the sorbic acid solution to flow on the inner wall of the crystallizer in a falling film manner to carry out gradual cooling for crystallization, gradually growing a uniform crystal layer on a heat exchange surface, and gradually enriching impurities in a mixture solution, wherein the concentration of the crystal layer is higher than the concentration of the mixture solution; and partially melting the crystal layer by adjusting the temperature of hot water through a heat exchanger to partially melt and eliminate low-melting point impurities included in the crystal layer in order to further purify crystals. The method has the advantages of simple process, compact device structure, reduction of the energy through adopting a falling film form, reduction of the cost and the device investment, and realization of high purity of the product produced by using the melting crystallizer.

Owner:于银强

Method for purifying dehydroacetic acid

The invention discloses a production process for preparing high purity dehydroacetic acid by virtue of melt crystallization. The process comprises the following steps of: firstly introducing frozen saline water into the bottom of an outer jacket of a melting crystallizer, wherein the frozen saline water uniformly flows in a falling film manner on the outer wall of the crystallizer; then inputting a concentrated dehydroacetic acid solution into the melting crystallizer, wherein the dehydroacetic acid solution flows in a falling film manner on the inner wall of the crystallizer and is gradually cooled to be crystallized; gradually growing a uniform crystal layer on a heat exchange face, wherein the concentration of the crystal layer is higher than that of a mixed solution, and impurities are gradually enriched in the mixture solution; and then adjusting the temperature of hot water by virtue of a heat exchanger to partly melt the crystal layer, namely a sweating operation, wherein low-melting-point impurities mingled in the crystal layer are partly melted and removed, so that the crystal is further purified. The process disclosed by the invention is simple, the equipment is compact in structure, and the energy is reduced in form of the falling film, and meanwhile, the cost and equipment investment are lowered; a product produced by the melting crystallizer is high in purity.

Owner:张勇

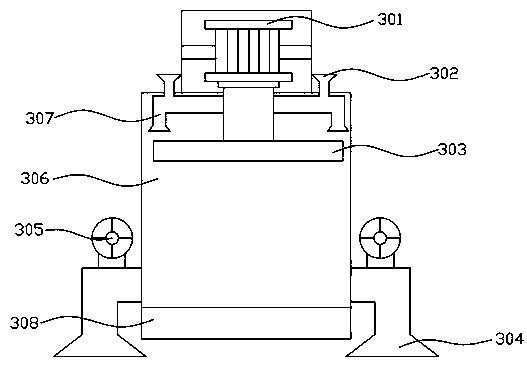

Hip fracture fixing device with adjustable supporting structure and triangular mechanical stable form

The invention provides a hip fracture fixing steel plate device with an adjustable supporting structure and a triangular mechanical stable form, and belongs to the technical field of hip fracture fixing. Comprising a steel plate, a guide part, an adjusting part, a limiting part and an anti-loosening part which are connected are arranged on the steel plate, and a supporting hole is formed in one side of the steel plate. The universality of a steel plate fixing model is improved, the difference of the fixing strength of a nail plate system caused by the bone anatomy difference of a patient is avoided, the clinical treatment level of the fracture patient is effectively guaranteed, the installation space of the supporting nails in the hip is effectively increased according to the hip structure, the overall stability effect of the steel plate is improved, and the stability of the whole steel plate is improved. The hip supporting strength of the steel plate fixing model is improved, the strength of the steel plate fixing model is further improved, adverse effects on a patient caused by fixing failure are avoided, and the use risk and the operation frequency of the patient are reduced.

Owner:FIRST HOSPITAL AFFILIATED TO GENERAL HOSPITAL OF PLA

Stereo matching optimization method for binocular vision system

InactiveCN103136750BReduce computing loadReduce the number of operationsImage analysisBinocular stereoVisual perception

The invention provides a stereo matching optimization method of a binocular visual system. The method comprises a step of using the binocular visual system to gain a binocular image; a step of correcting a distortion and polar line of the binocular visual system; a step of transferring the binocular image from a colorful image into a grayscale image; a step of regarding one of the grayscale images as a basic standard and matching with another image according to pixel masterplate; a step of optimizing ZNCC factor; a step of regarding the optimized ZNCC as a similarity measure to calculate in a matched mode so as to ensure matching parallax of each pixel point; a step of producing a dense disparity map according to the matching parallax of each pixel point. The method has the advantages of reducing times of calculation greatly and reducing calculating load of computer chip greatly by optimizing a computational formula of the ZNCC factors and calculating method. The method can improve real-time performance of the stereo matching as well as reducing cost of day-to-day and military high-precision image identification.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Operation method of fast erasable and rewritable memory with symmetrical double-channel

InactiveCN1179363CIncrease the number of operationsImprove reading speedSemiconductor/solid-state device manufacturingDigital storageEngineeringElectrical and Electronics engineering

There is a manipulating method for flash memory with a symmetrical dual channel, it at least includes: at first, it writes procedure into quick erasable memory, makes the charge locate at both side sof ONO layer in the second wire in order to form the symmetrical dual channel structure, and accomplishes writing operation of one bit, then it transmits the selective voltage to the first and the third bit with in order to select the second bit wire for symmetrical structure. Following the second bit wire should be grounded. Then the reading voltage is transmitted to the second letter wire, at the same time it collects reading current, and the current is the total of current which pass through the symmetrical dual channel, so the speed of reading of flash memory is advanced.

Owner:MACRONIX INT CO LTD

Deep learning network application distributed self-assembly instruction processor core, processor, circuit and processing method

ActiveCN110516800BConfigurableReduce usageNeural architecturesPhysical realisationComputer architectureSelf assemble

The disclosure discloses a deep learning network application distributed self-assembly instruction processor core, a processor, a circuit and a processing method. The processor core includes: four register interface modules, and two register interface modules are arranged in sequence. A preparation module, a convolution operation module, and a pooling operation module; the processor includes: the instruction statistics distribution module configured to count deep convolutional network instructions and distribute instruction streams; the instruction statistics distribution module respectively The processor core is connected through an instruction stack module, and the instruction stack module is configured to receive and store the instruction stream allocated by the instruction statistics distribution module, and perform multi-instruction stream acceleration operations according to the stored instruction stream, and control all The above-mentioned processor cores form different deep neural convolutional network architectures for calculation and processing.

Owner:SHANDONG NORMAL UNIV

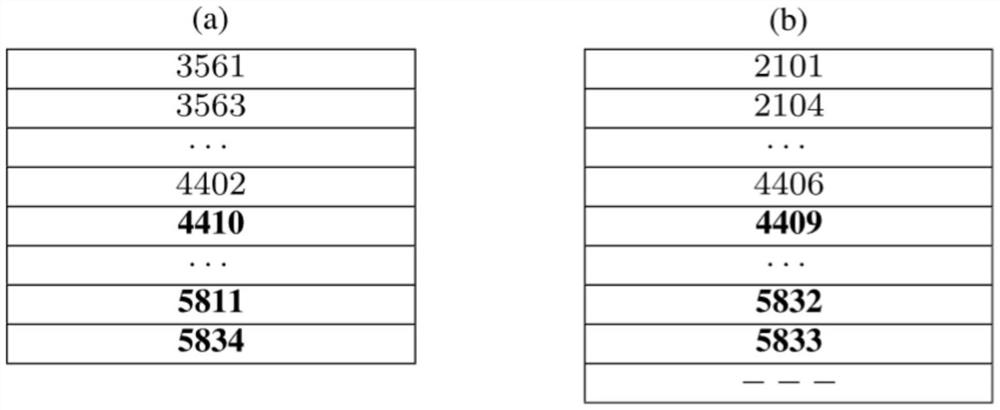

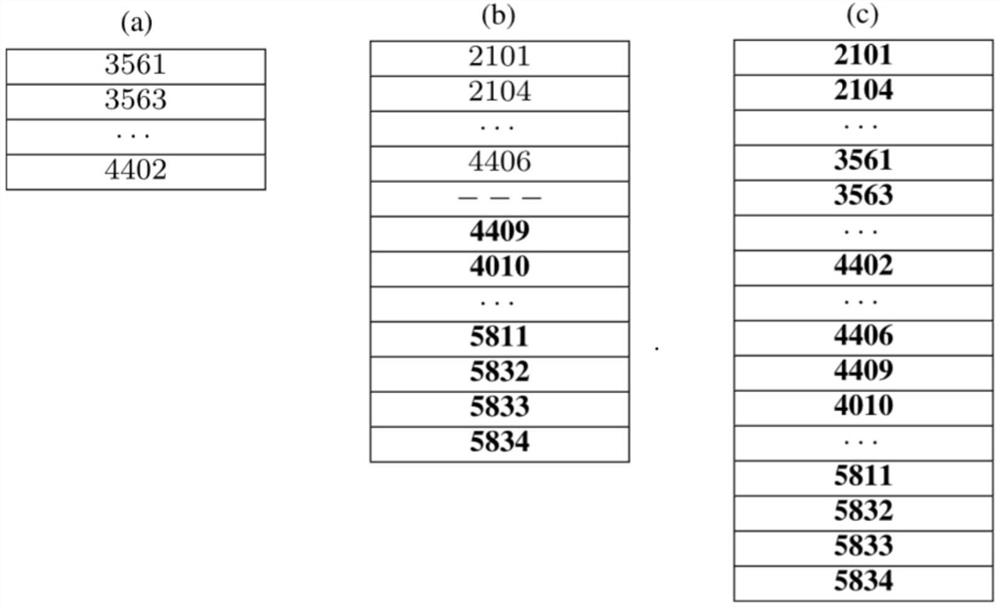

An Efficient LTL Model Checking Method for Large-Scale Systems

InactiveCN106293544BReduce complexityIncrease the number of operationsInput/output to record carriersAlgorithmLinear temporal logic

The invention discloses a high-efficient LTL (Linear Temporal Logic) model detection method of large scale system. The LTL model detection method is characterized in that by adopting an LHS (Linear Hash Storage) algorithm, hash values stored in hash tables in a hard disc can be quickly found, and the hash tables can be stored in an outer memory by a new technique no matter whether the classification of the hash tables in an inner memory is empty or not, and the complexity of I / O (input / output) is the linearity size of the hash tables; by adopting a CDD (Cache Copy Detection) technique, a copy in the inner memory can be detected by effective accessing; by adopting HLS and CDD, the complexity of copy detection can be decreased; by adopting a DPM (dynamic path management) plan, the two embedded deep priority stacks can dynamically share an inner memory unit, and the jittering of the inner memory is solved by the effective stacking and state management, wherein the jittering of the inner memory refers to the frequent movement of the state in the inner memory, which may cause obvious increasing of I / O operation times, thereby reducing the algorithm efficiency.

Owner:CHENGDU KEHONGDA TECH

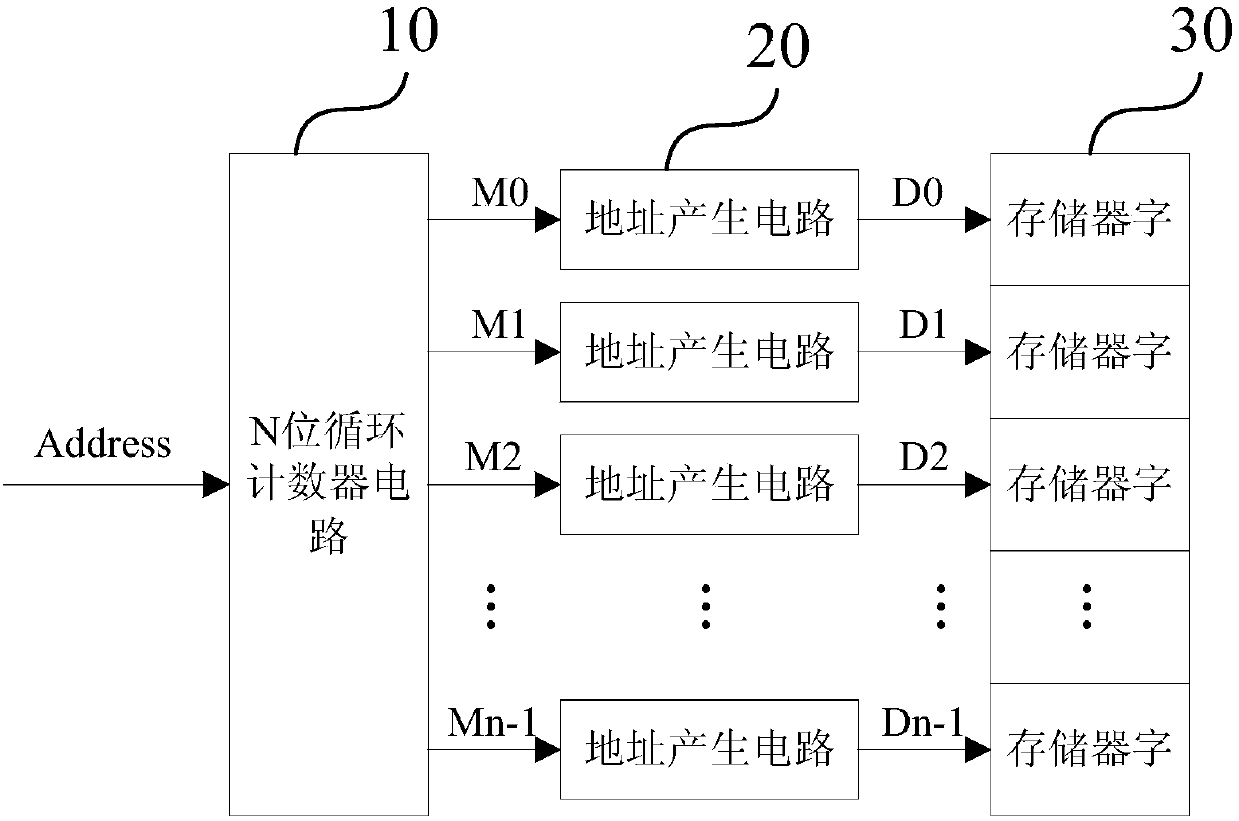

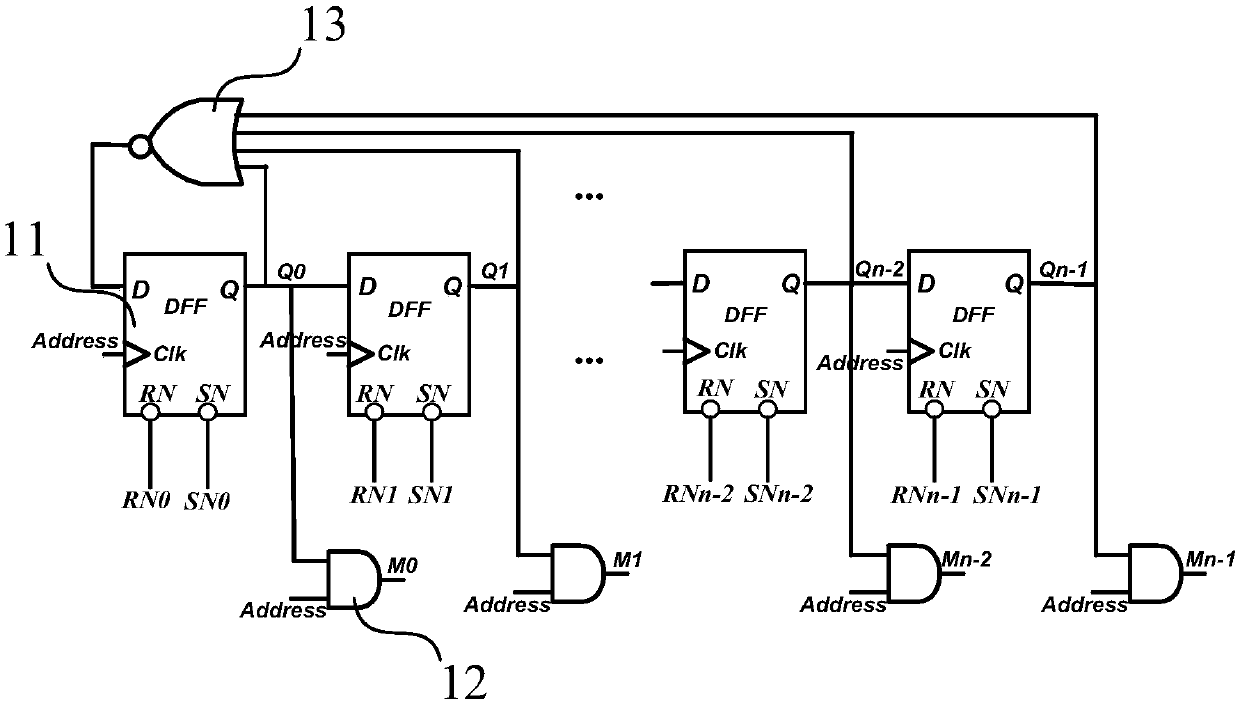

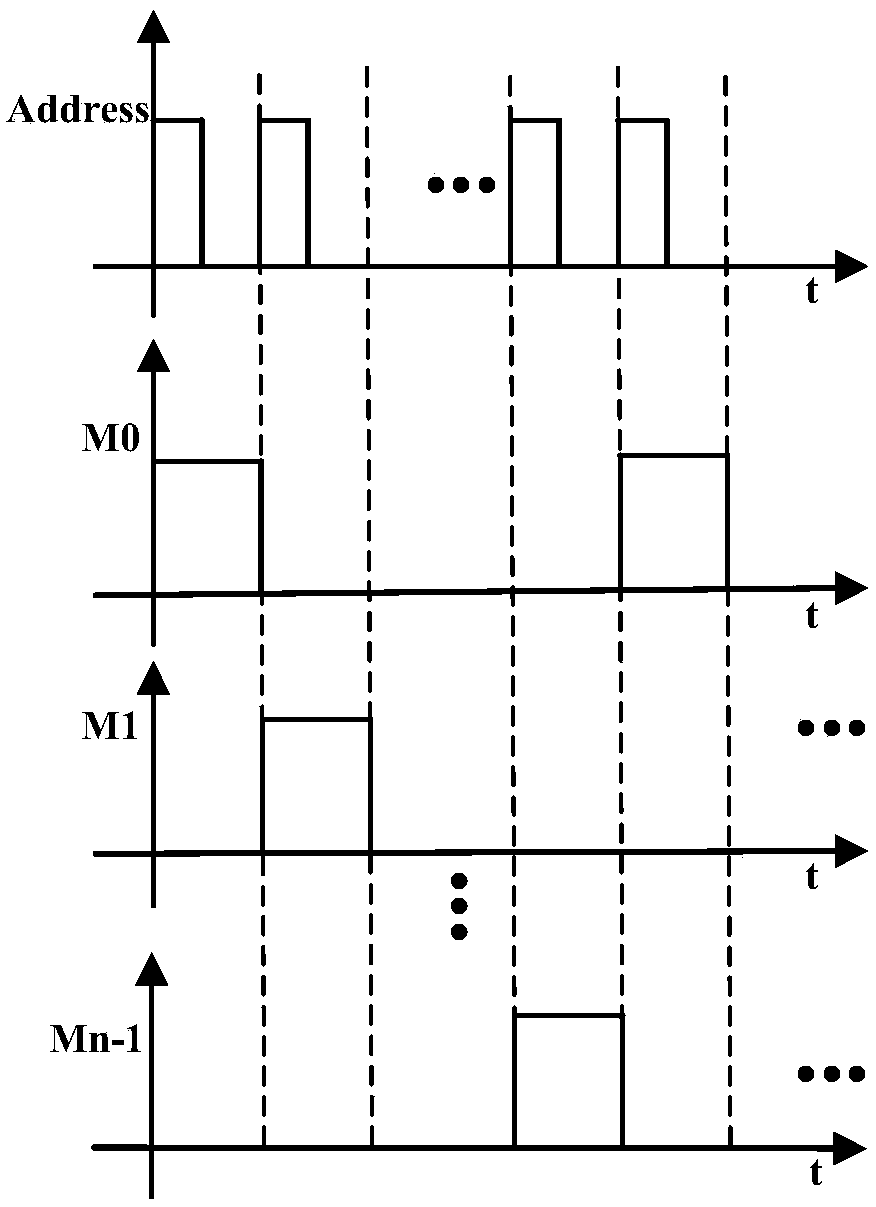

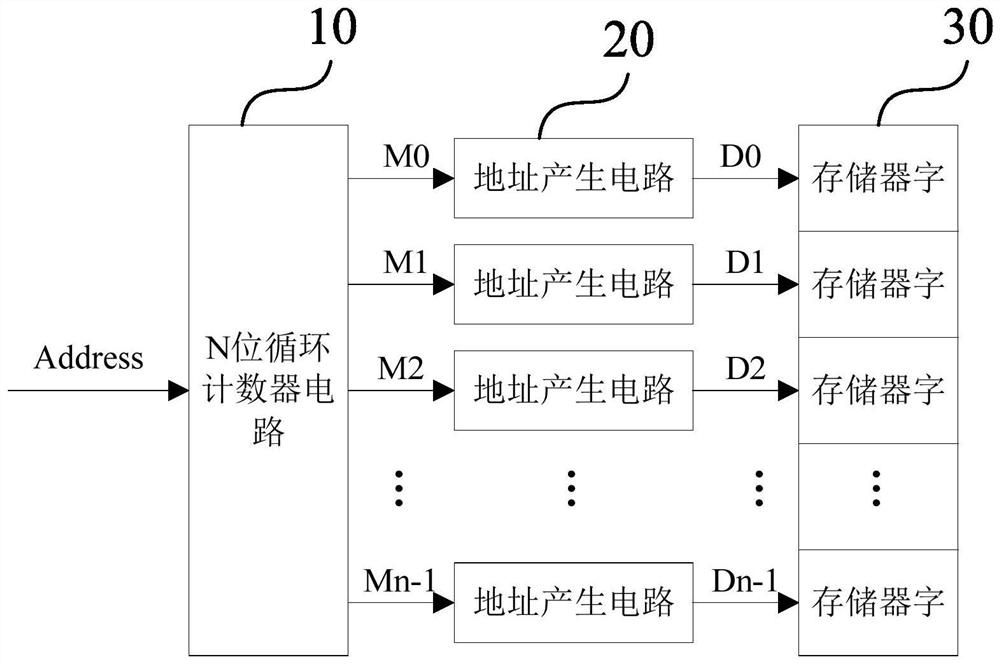

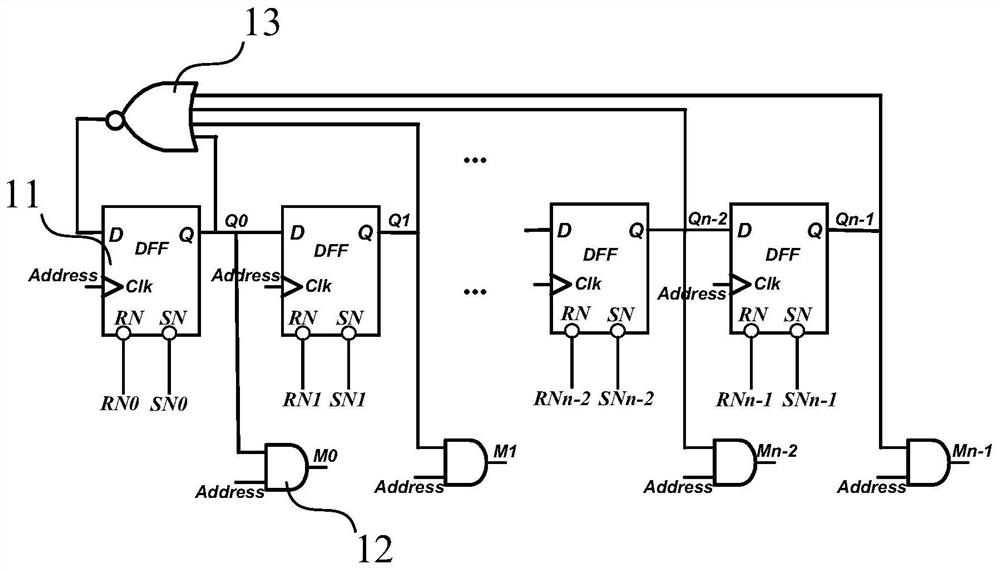

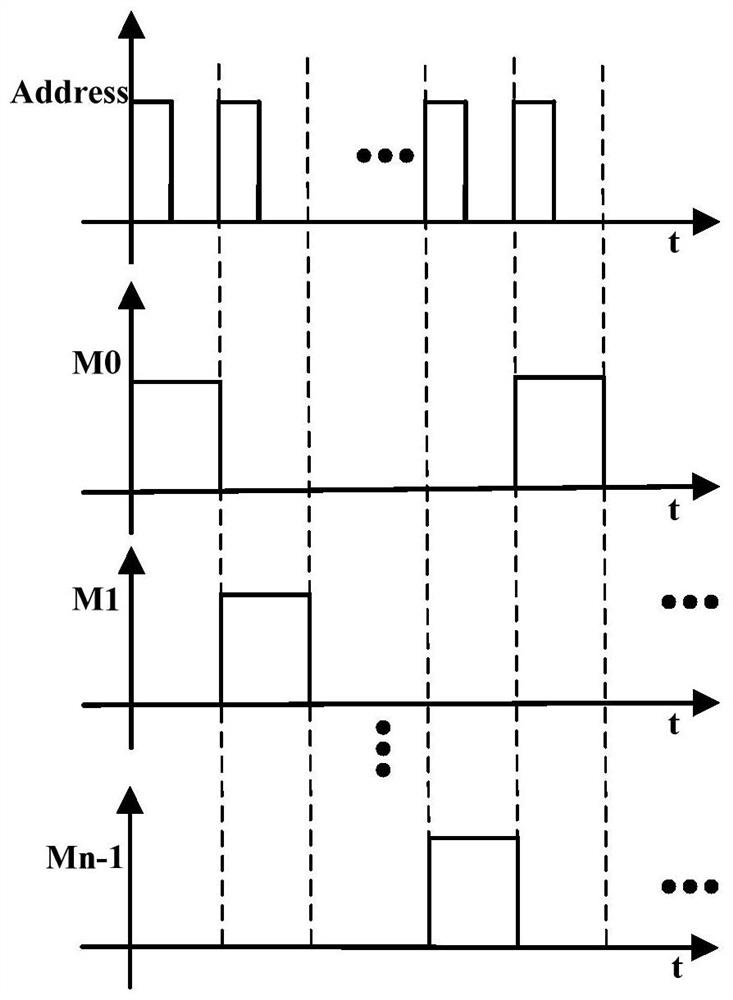

Circuit structure and method for expanding number of operation times of memory

The invention provides a circuit structure and method for expanding the number of operation times of a memory. The circuit structure comprises an N-bit cycle counter circuit, N address generation circuits and a memory array; the N address generation circuits are connected with the N-bit cycle counter circuit; the memory array is connected with the N address generation circuits; N times of operations on a memory word are dispersed into N different memory words; therefore, excessive operation on a memory word is avoided; when the power is off every time, the state of a trigger circuit is storedin a non-volatile phase change memory; when the power is on every time, the data in the non-volatile phase change memory is read out; therefore, the trigger circuit and the N-bit cycle counter circuitrecover to the state before the power is off; and thus, balanced operation of the memory words in any condition can be realized. By means of the circuit structure and method for expanding the numberof operation times of the memory provided by the invention, the problem that a phase change memory cannot realize the reading, writing and erasing balance of each memory unit in the prior art can be solved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Optical information recording apparatus

ActiveCN1838264AIncrease the number of timesReduce deteriorationRecording verificationRecord information storageComputer scienceOptical disc

Owner:VICTOR CO OF JAPAN LTD

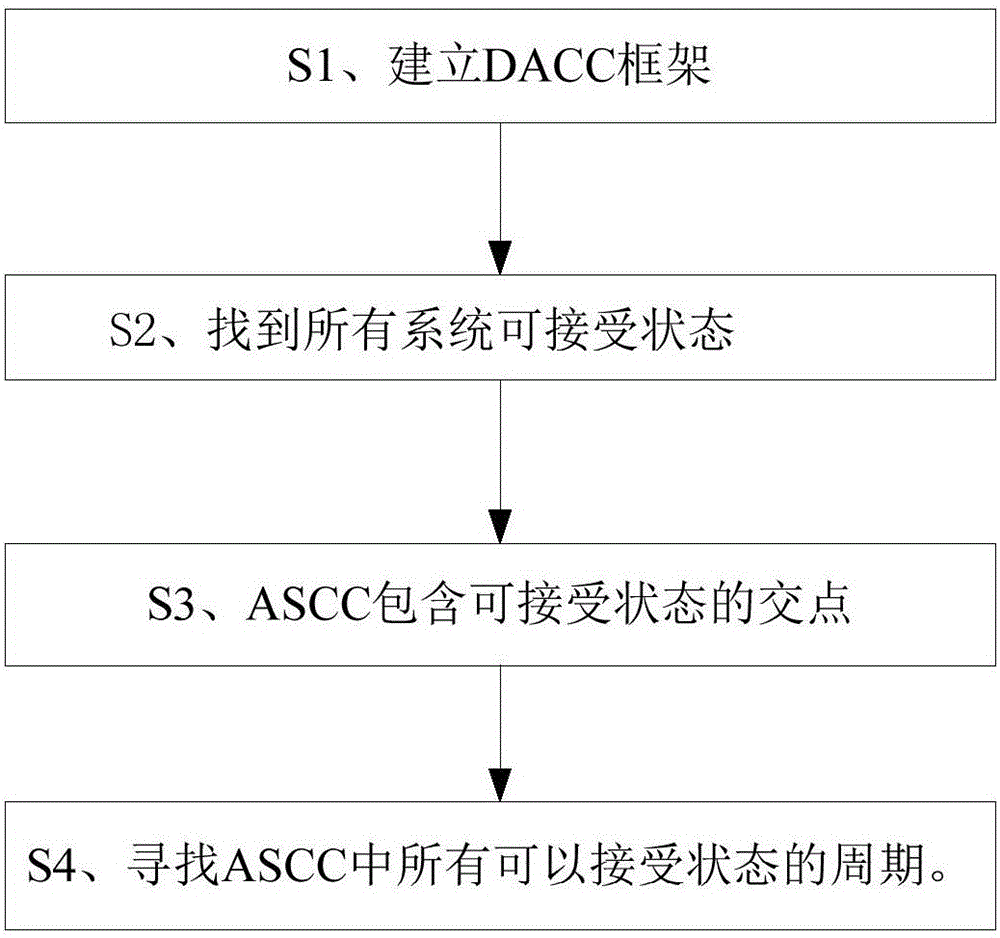

IO efficient detection method of large-scale system loop

PendingCN106339287AAvoid searchingReduce complexitySoftware testing/debuggingFaulty hardware testing methodsAlgorithm

The invention discloses an IO efficient detection method of a large-scale system loop. A general frame is constructed to search all counter examples; for each acceptable state, DACC firstly searches the acceptable state contained in ASCC, and then, all acceptable loops of the ASCC are found. The IO efficient detection method has the advantages that a great quantity of useless paths can be prevented from being searched, and the useless paths cannot reach the acceptable loops. In order to further lower I / O complexity and improve the manifestation of the method disclosed by the invention, the invention puts forward a technology for calculating two state intersections and a dynamic path management technology. The poorest I / O complexity in the intersection calculation technology is linear, and therefore, the manifestation of an algorithm for searching ASCCs can be improved. The dynamic path management technology can be used for reducing a memory thrashing phenomenon during searching so as to improve the manifestation of algorithms for finding all acceptable state algorithms.

Owner:CHENGDU KEHONGDA TECH

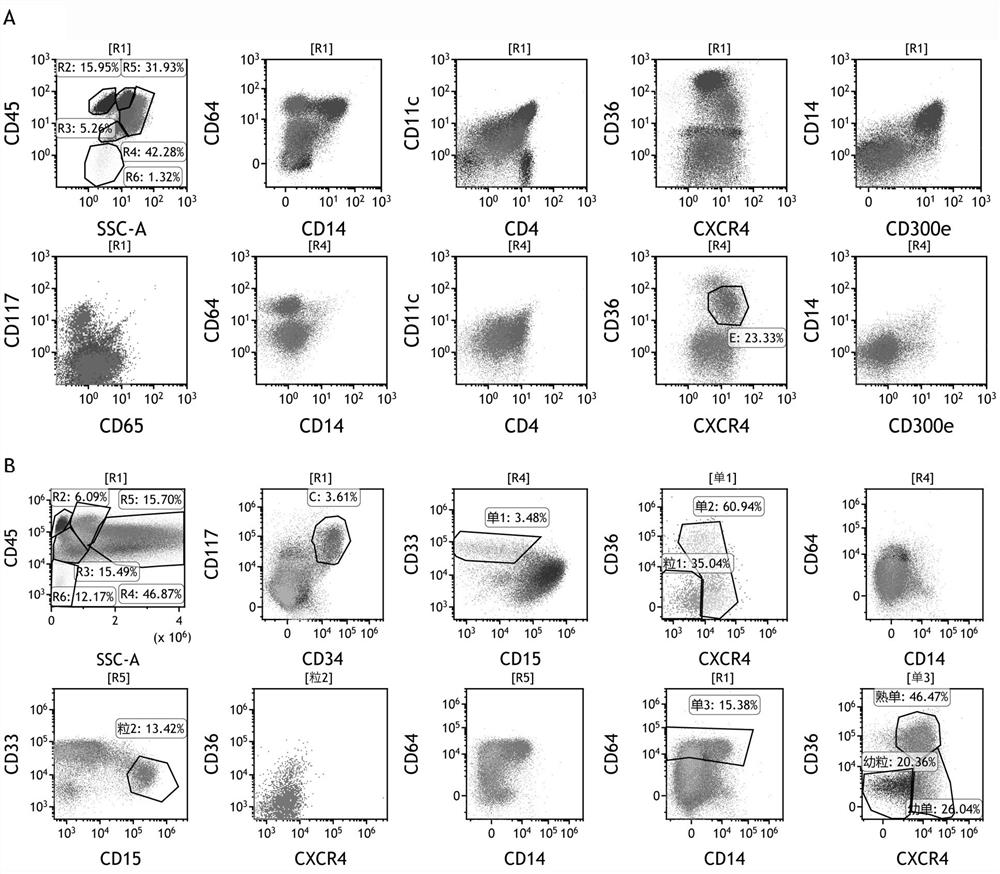

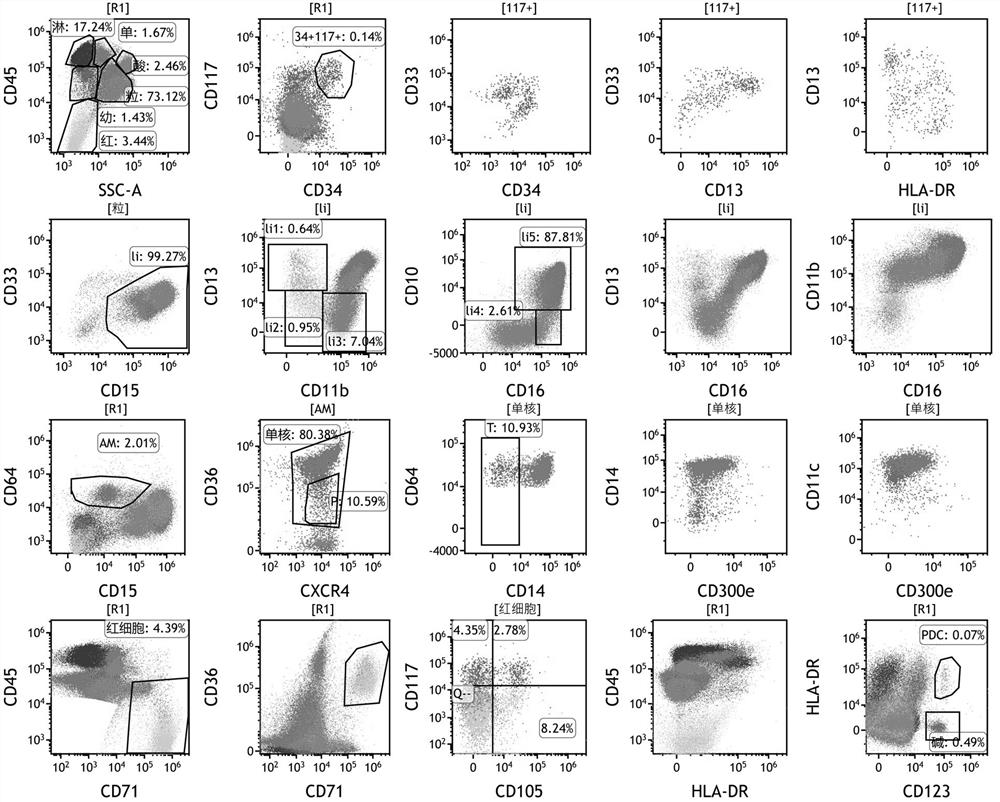

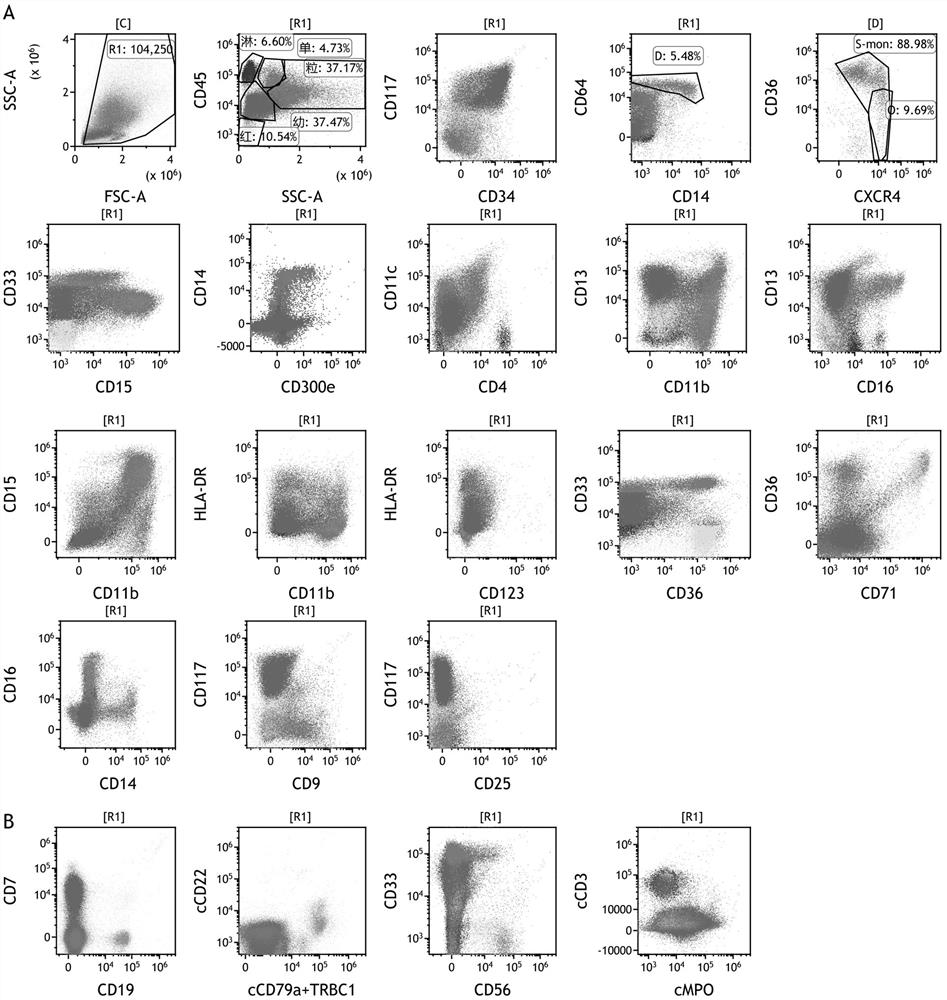

A group of antibody compositions for immunophenotyping of myeloid tumors and their applications

ActiveCN114213540BImprove accuracyImprove featuresImmunoglobulins against cell receptors/antigens/surface-determinantsDisease diagnosisMRD NegativeOncology

The present invention relates to the field of antibody medicine, in particular to a group of antibody compositions for immunophenotyping of myeloid tumors and applications thereof, wherein the antibody compositions comprise a group of 22-24 antibody combinations. The invention optimizes the antibody combination and the corresponding antibody fluorescent labeling combination and the result interpretation method, and only needs to use a tube of 22 or 24 kinds of antibodies and a tube of cells to be sampled at one time, which can comprehensively and efficiently carry out subclassification of AML and chronic myeloid tumors. It can predict CML and some recurrent genetically abnormal AML, and has a high sensitivity for the diagnosis of MDS. At the same time, the leukemia-associated immunophenotype (LAIP) that can be used for post-treatment minimal residual disease (MRD) monitoring in this combination can be determined.

Owner:PEOPLES HOSPITAL PEKING UNIV

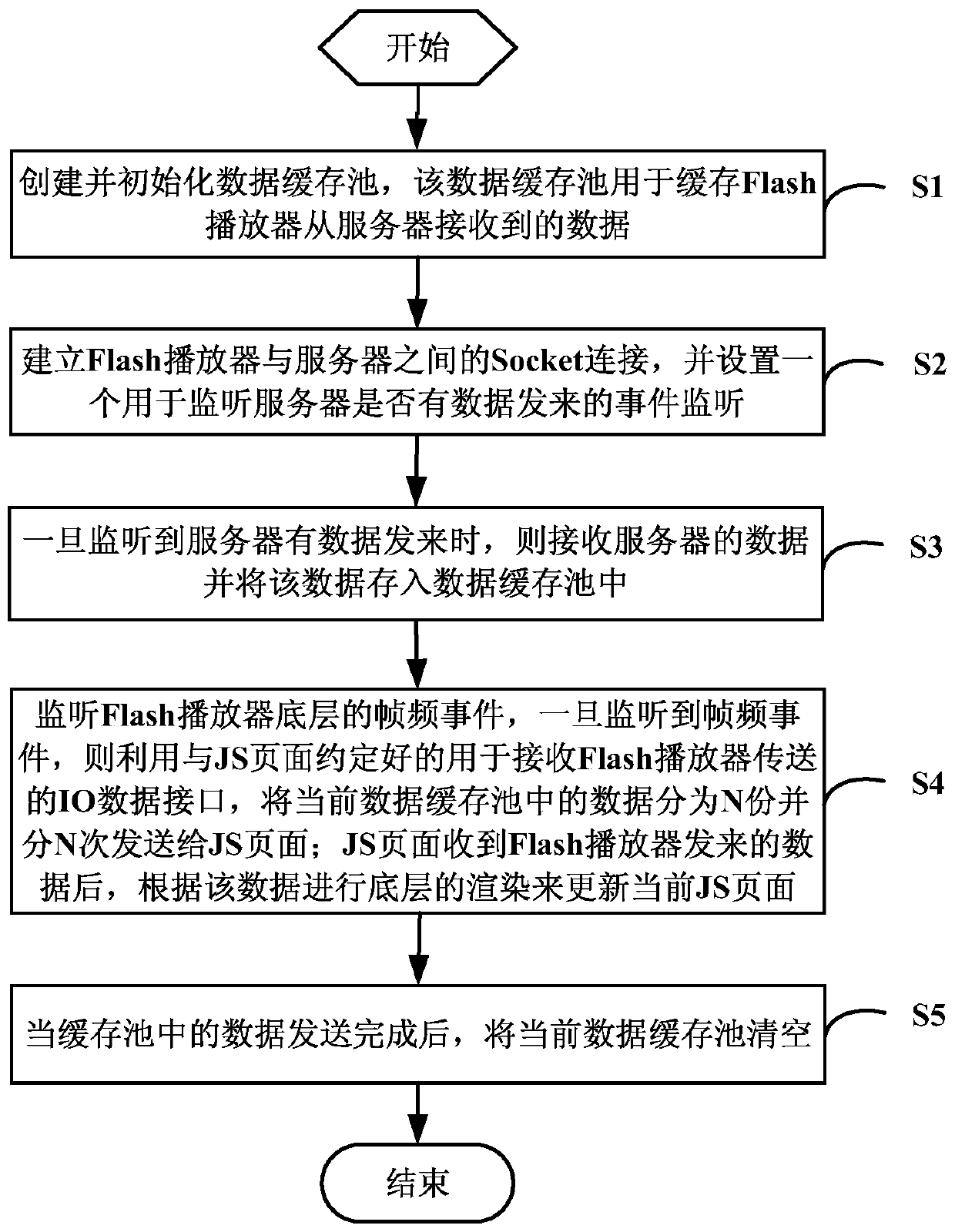

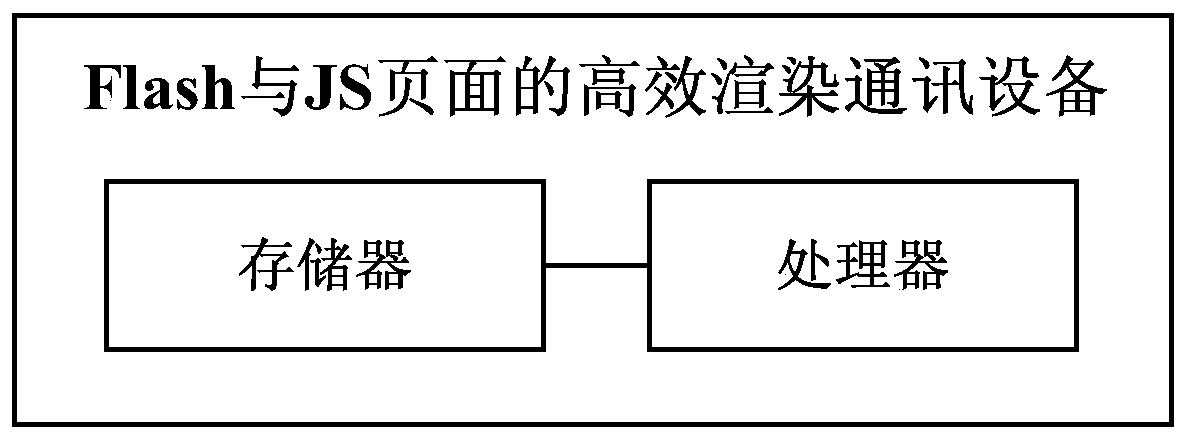

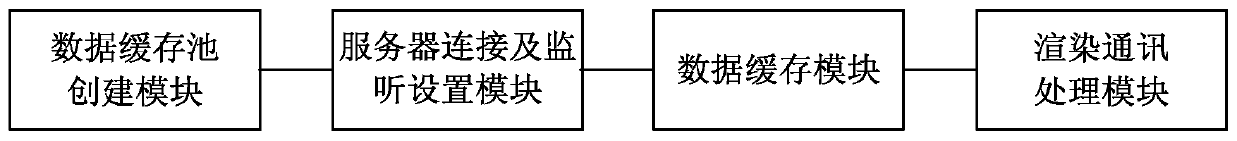

Efficient rendering communication method, storage medium, device and system for flash and js pages

ActiveCN107743266BIncrease consumptionGuaranteed not to freezeTransmissionSelective content distributionEngineeringPool

Disclosed in the present invention are a Flash and JS page efficient rendering communication method, a storage medium, a device, and a system, relating to the technical field of Flash live broadcast development. The method comprises: creating and initialising a data cache pool; establishing a socket connection between a Flash player and a server, and setting up event monitoring; when monitoring that the server has data for transmission, receiving the data of the server and storing same in the data cache pool; monitoring for frame rate events on the bottom layer of the Flash player, and when monitoring a frame rate event, using an IO data interface, dividing the data currently in the data cache pool into N parts and sending same to a JS page N times; after receiving the data sent by the Flash player, the JS page performs bottom layer rendering on the basis of the data to update the current JS page. The present invention can solve the problem of performance bottlenecks due to the large amount of communication between the Flash player and the JS page during the rendering process, such that the rendered image does not freeze, and the user experience is good.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

A method for purifying dehydroacetic acid

The invention discloses a production process for preparing high-purity dehydroacetic acid by virtue of a melt crystallizer. The production process comprises the following steps: introducing freezing saline water into the bottom of a jacket of the melt crystallizer, enabling the freezing saline water to uniformly flow at the outer wall of the crystallizer in a falling film manner, putting a condensed dehydroacetic acid solution into the melt crystallizer, enabling the condensed dehydroacetic acid solution to flow down at the inner wall of the crystallizer in the falling film manner so as to be gradually cooled and crystallized, gradually growing a uniform crystal layer on a heat exchanging face, and gradually enriching impurities in a mixture solution, wherein the concentration of the uniform crystal layer is higher than that of the mixture solution; regulating the temperature of hot water by utilizing a heat exchanger to carry out partial melting operation, namely a sweating process, on the crystal layer, and partially melting and eliminating low-melting-point impurities included in the crystal layer, so as to further purify crystals. The production process has the advantages that the process is simple, and the structures of devices are compact; by utilizing the falling film manner, the energy is reduced, and meanwhile, the cost and the equipment investment are lowered; the purities of products produced by utilizing the melt crystallizer are high.

Owner:NANTONG ALCHEMY BIOTECH DEV

A circuit structure and method for expanding memory operation times

The invention provides a circuit structure and method for expanding the number of operation times of a memory. The circuit structure comprises an N-bit cycle counter circuit, N address generation circuits and a memory array; the N address generation circuits are connected with the N-bit cycle counter circuit; the memory array is connected with the N address generation circuits; N times of operations on a memory word are dispersed into N different memory words; therefore, excessive operation on a memory word is avoided; when the power is off every time, the state of a trigger circuit is storedin a non-volatile phase change memory; when the power is on every time, the data in the non-volatile phase change memory is read out; therefore, the trigger circuit and the N-bit cycle counter circuitrecover to the state before the power is off; and thus, balanced operation of the memory words in any condition can be realized. By means of the circuit structure and method for expanding the numberof operation times of the memory provided by the invention, the problem that a phase change memory cannot realize the reading, writing and erasing balance of each memory unit in the prior art can be solved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

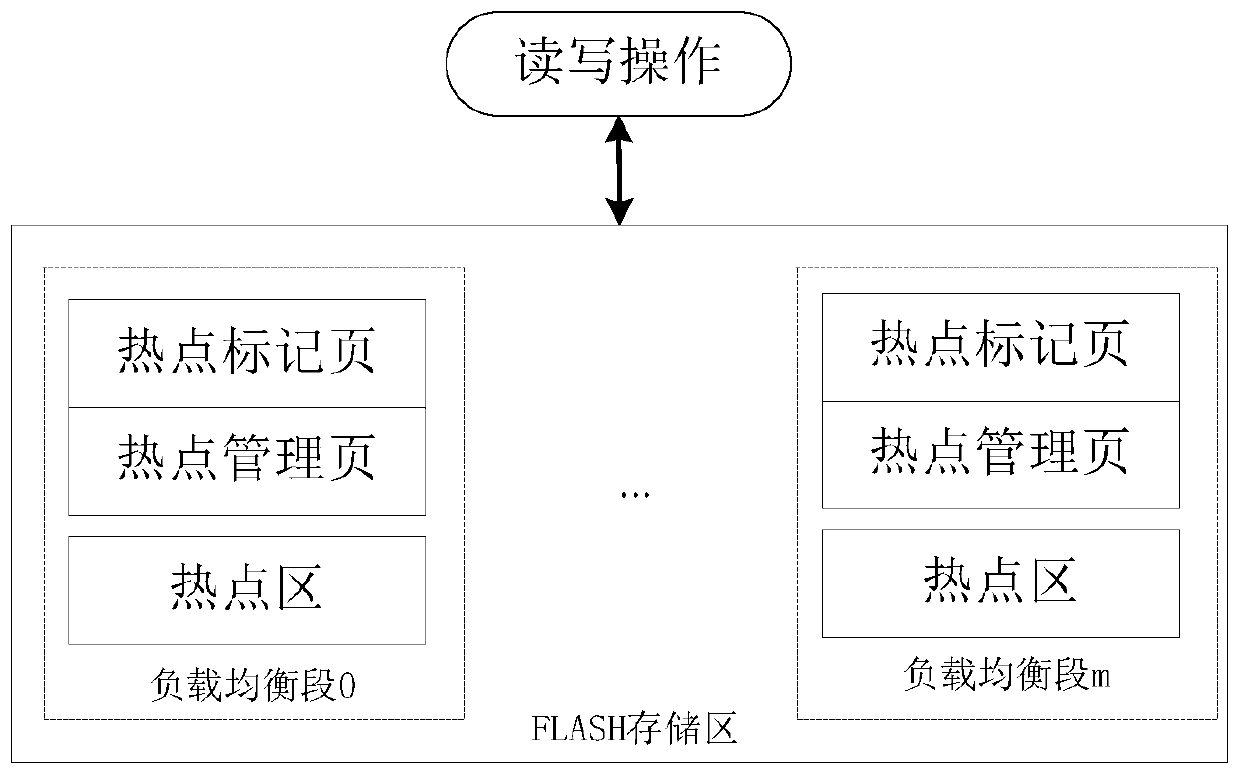

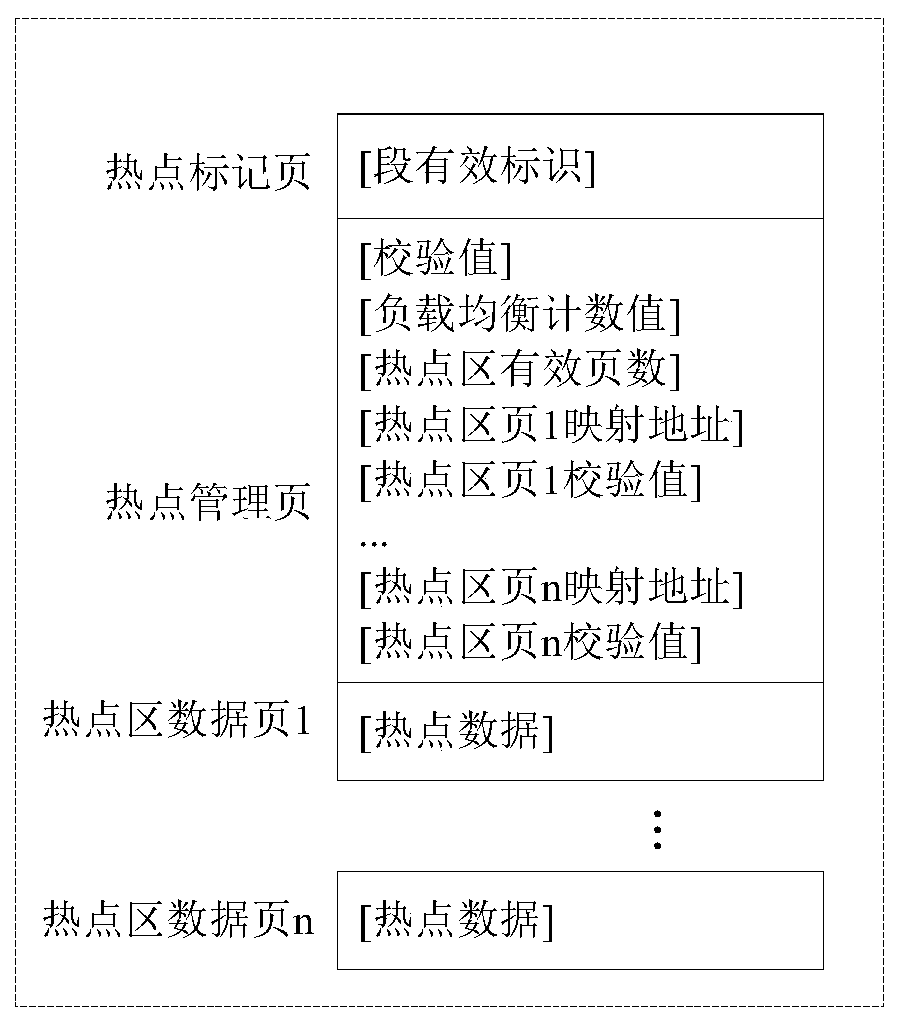

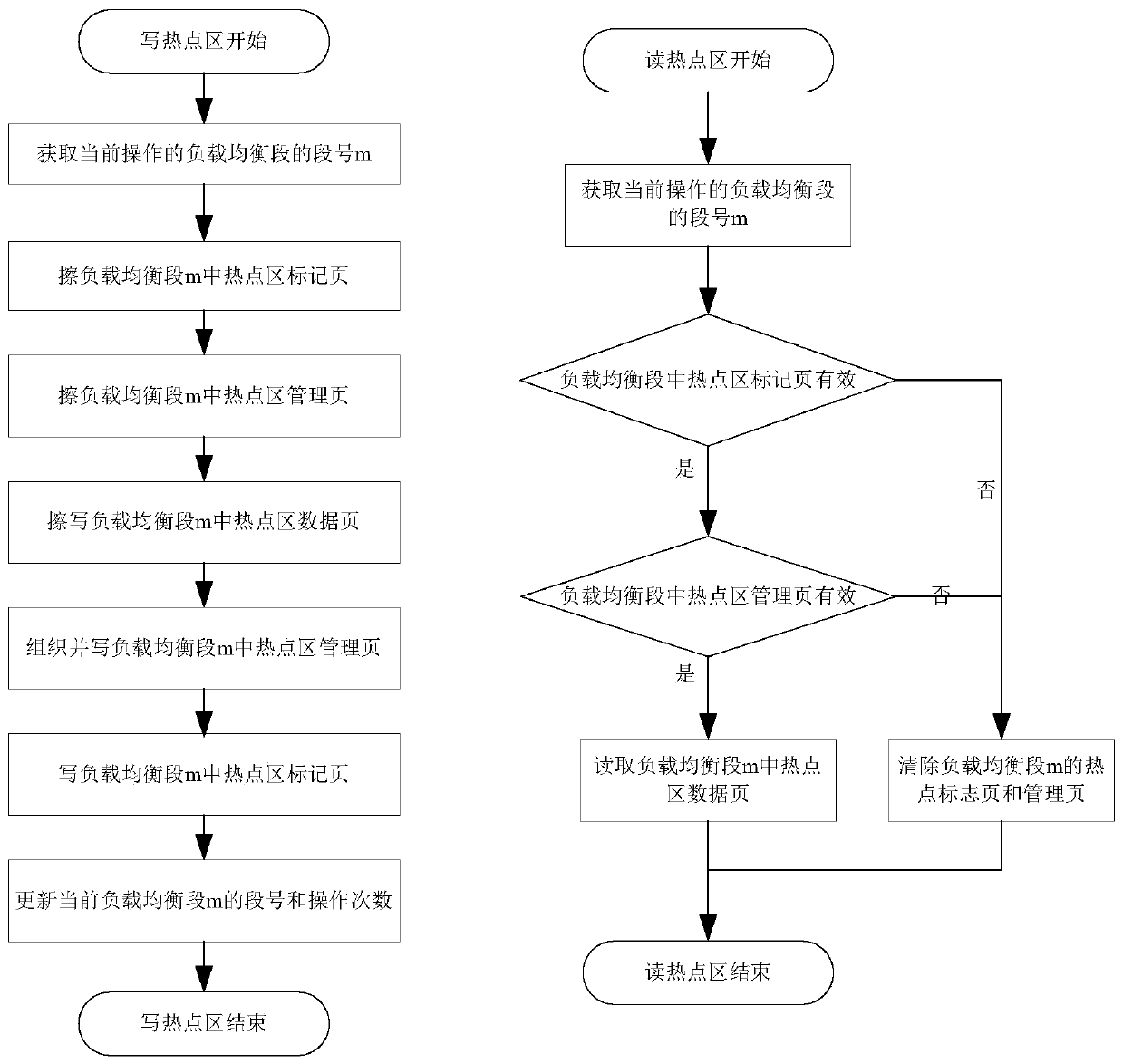

Load balancing method for prolonging service life of hotspot region

InactiveCN111078142AImprove reliabilityReduced lifetime bottleneckInput/output to record carriersSoftwareSystems engineering

The invention discloses a load balancing method for prolonging the service life of a hot spot region, and relates to responding to an access request of a user to a hot spot region in a FLASH memory. The method comprises: according to a load balancing section global variable of current operation, operating the corresponding load balancing section, judging effectiveness of the current load balancingsection and correctness of read-write operation before the operation, completing read-write operation of the hot spot region, and updating the global variable and management information of the load balancing section of the current operation at the same time to prepare for the next read-write operation of the load balancing section. According to the method introduced in the invention, a pure software method can be used, the number of load balancing sections of the FLASH memory is configured, the read-write operation load of the hot spot region of the FLASH memory is dynamically balanced, the service life of the hot spot region is prolonged, the overall reliability of the FLASH is improved, the requirements of different users for the reliability of the FLASH memory, especially the bottleneck of the service life of the hot spot region are met, and the development efficiency is improved.

Owner:BEIJING CEC HUADA ELECTRONIC DESIGN CO LTD

A kind of method of purifying sorbic acid

ActiveCN103694105BSimple processGood choiceCarboxylic compound separation/purificationBiotechnologySaline water

Owner:NANTONG ALCHEMY BIOTECH DEV

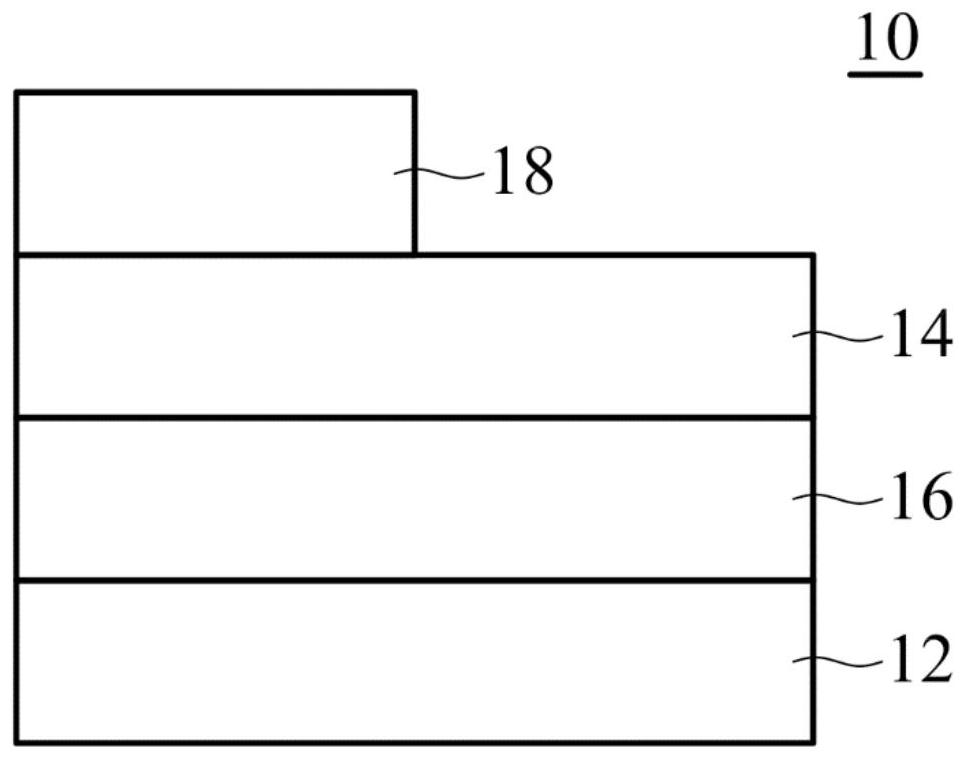

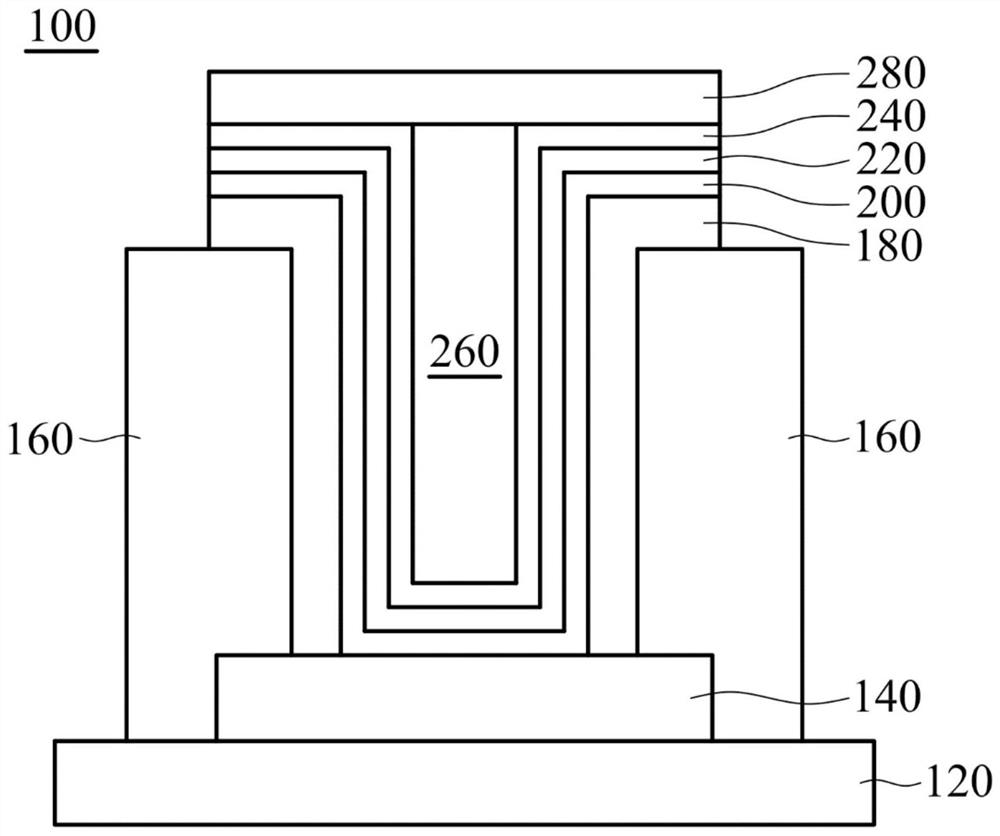

Ferroelectric memory

PendingCN112928116AStabilized ferroelectric propertiesBoost actionsSolid-state devicesDigital storageMaterials scienceEngineering physics

The invention provides a ferroelectric memory. The memory comprises: a first electrode layer, wherein the main crystallization direction of the first electrode layer comprises(110) or (220); a second electrode layer arranged opposite to the first electrode layer, wherein the main crystallization direction of the second electrode layer comprises (110) or (220); and a ferroelectric layer arranged between the first electrode layer and the second electrode layer, wherein the main crystallization direction of the ferroelectric layer is (111).

Owner:IND TECH RES INST

High-efficient LTL (Linear Temporal Logic) model detection method of large scale system

InactiveCN106293544AReduce complexityIncrease the number of operationsInput/output to record carriersLinear temporal logicState management

The invention discloses a high-efficient LTL (Linear Temporal Logic) model detection method of large scale system. The LTL model detection method is characterized in that by adopting an LHS (Linear Hash Storage) algorithm, hash values stored in hash tables in a hard disc can be quickly found, and the hash tables can be stored in an outer memory by a new technique no matter whether the classification of the hash tables in an inner memory is empty or not, and the complexity of I / O (input / output) is the linearity size of the hash tables; by adopting a CDD (Cache Copy Detection) technique, a copy in the inner memory can be detected by effective accessing; by adopting HLS and CDD, the complexity of copy detection can be decreased; by adopting a DPM (dynamic path management) plan, the two embedded deep priority stacks can dynamically share an inner memory unit, and the jittering of the inner memory is solved by the effective stacking and state management, wherein the jittering of the inner memory refers to the frequent movement of the state in the inner memory, which may cause obvious increasing of I / O operation times, thereby reducing the algorithm efficiency.

Owner:CHENGDU KEHONGDA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com