Production method for dry solid containing fine cellulose fibers, dry solid containing fine cellulose fibers, redispersion of fine cellulose fibers

A technology of fine cellulose and solid matter, applied in the field of fine cellulose fiber redispersion, can solve the problems of increased cost and limited use of CNF, and achieve good redispersibility, excellent redispersibility, and excellent viscosity characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

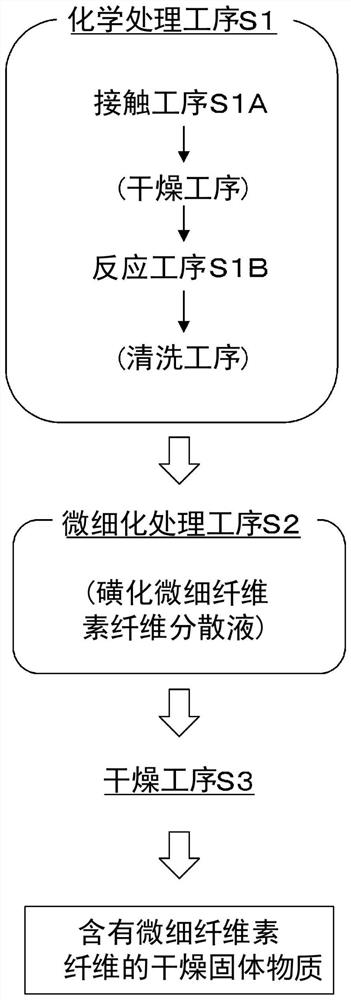

Method used

Image

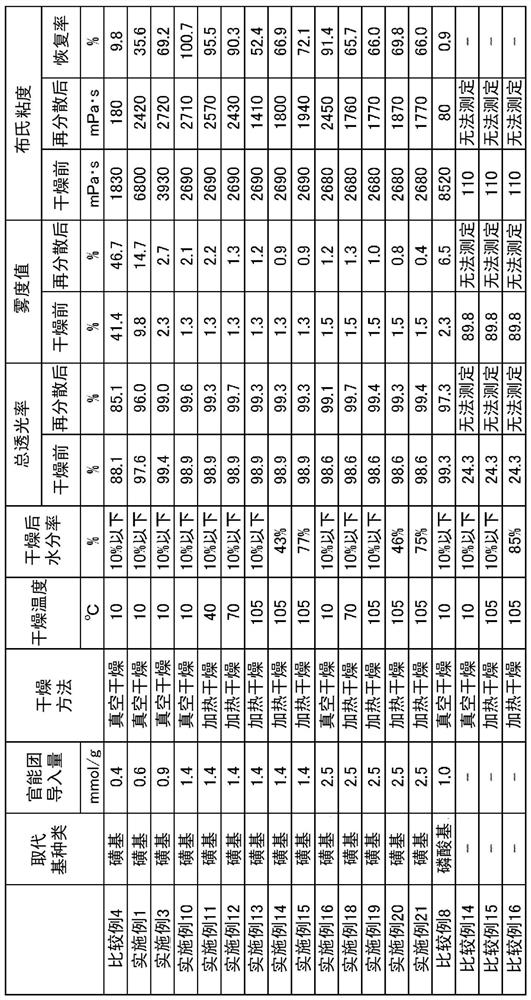

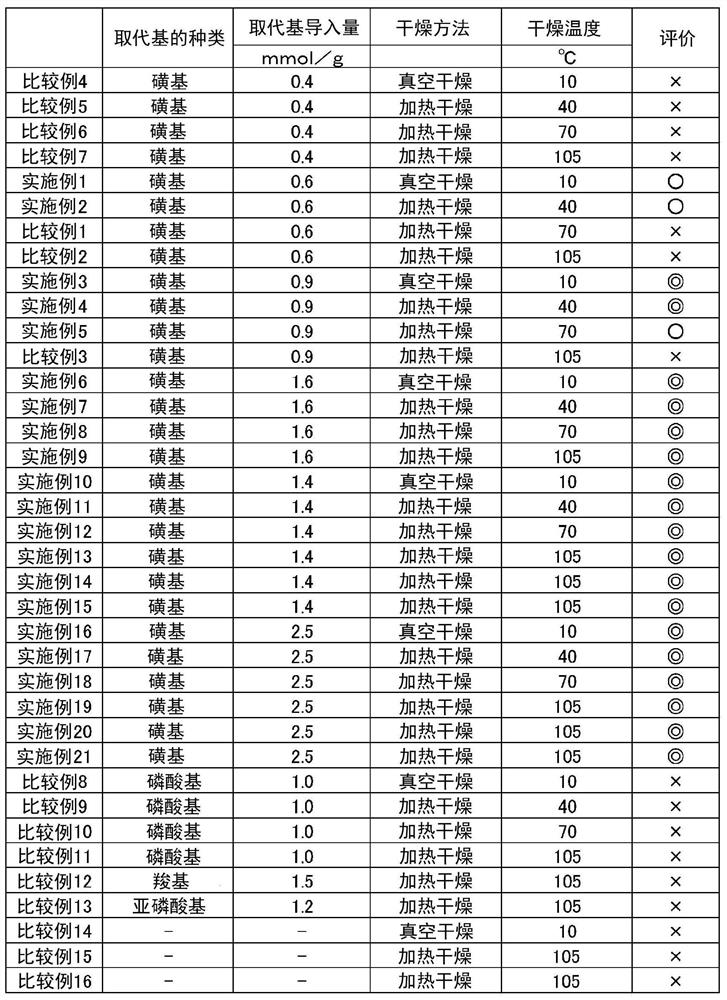

Examples

Embodiment 1

[0175]

[0176] Softwood kraft pulp (NBKP manufactured by Marusumi Paper Co., Ltd.) was used. Hereinafter, only NBKP used in the experiment will be described as pulp. The pulp was washed with a large amount of pure water, drained with a 200-mesh sieve, and used for the experiment after measuring the solid content concentration.

[0177] (chemical treatment process)

[0178] The pulp was added to the reaction liquid prepared as follows and stirred into a paste. In addition, the process of adding pulp to a reaction liquid and making it into a paste corresponds to the contact process of the chemical treatment process of this embodiment.

[0179] (Preparation process of reaction solution)

[0180] The sulfonating agent and urea and / or its derivatives were prepared so as to have the following solid content concentrations.

[0181] In the experiment, sulfamic acid (purity: 98.5%, manufactured by Fuso Chemical Industry Co., Ltd.) was used as a sulfonating agent, and urea soluti...

Embodiment 2

[0226] In a drying process, it implemented similarly to Example 1 except having heat-dried with the dryer which set the temperature of a thermostat to 40 degreeC.

Embodiment 3

[0228] In the preparation process of the reaction liquid, the reaction liquid adjusted to sulfamic acid / urea ratio ((g / L) / (g / L))=200 / 200 was used, so that sulfamic acid It carried out similarly to Example 1 except having prepared so that it may be 1000 weight part, and urea shall be 1000 weight part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com