Non-layering cosmetic powder uniform mixing equipment

A technology for cosmetics and powders, which is applied to mixers with rotating containers, mixers with rotating stirring devices, mixers, etc. It can solve the problems that the pre-mixed structure cannot be combined with the organic combination of the mixed structure, and the short following path affects the mixing quality. , to achieve the effect of improving the mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

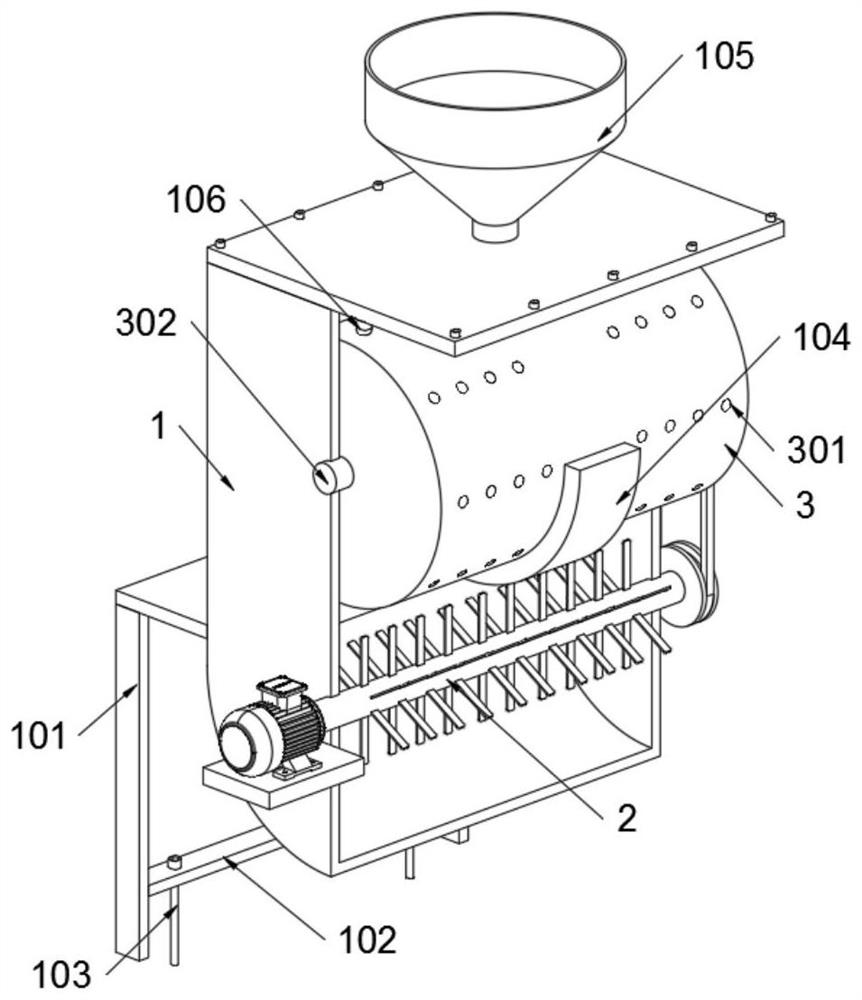

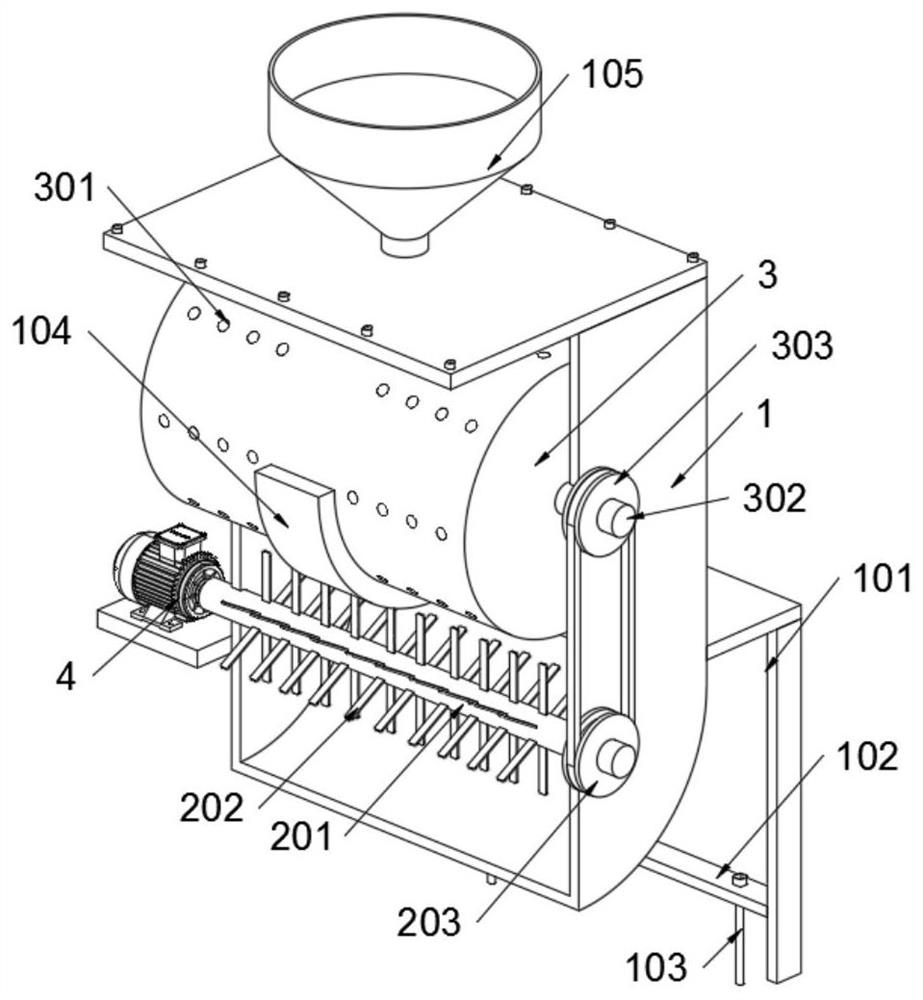

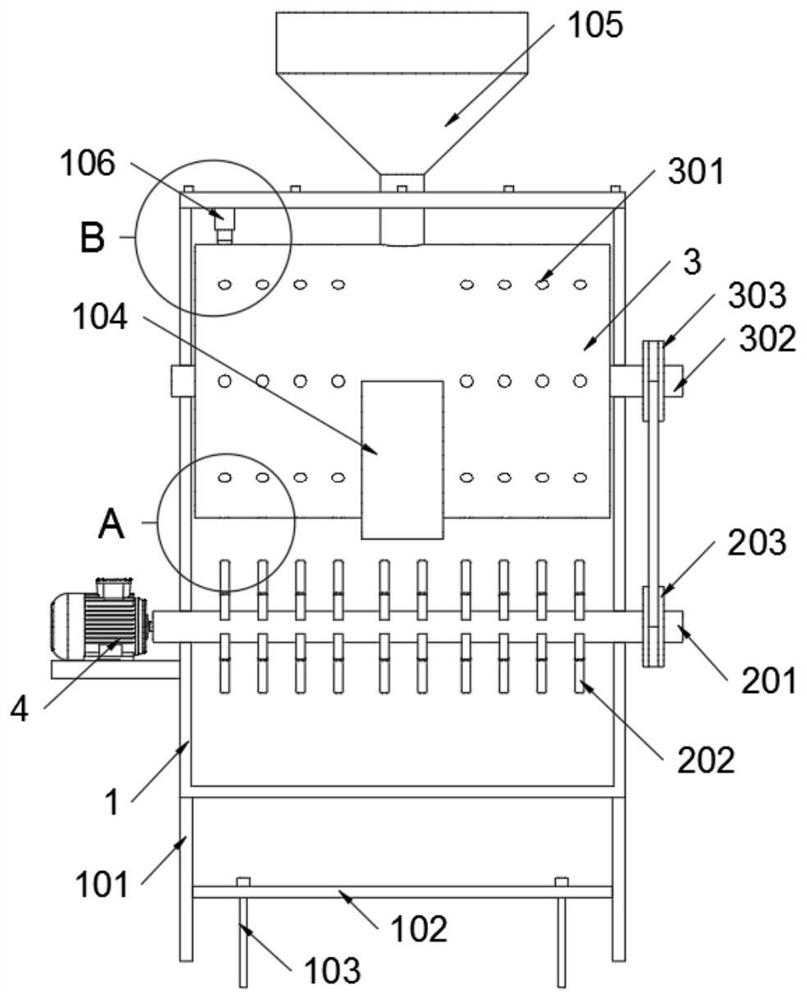

[0033] Append figure 1 Adherent Figure 8 Down:

[0034] The present invention provides a non-moisture-free cosmetic powder mixing apparatus, including a casing 1; a mixed structure 2 is mounted in the casing 1, and the casing 1 rotates the cylinder body 3, and the casing 1 is fixed by bolt Connected to drive motor 4; reference figure 1 with Figure 6The box 1 includes an elastic telescoping rod 106, and the elastic telescopic rod 106 is fixed to the inner wall of the casing 1 by a bolt, and the elastic telescoping rod 106 is a hemispherical structure; the elastic telescopic rod 106 is positive, and the elasticity The telescopic rod 106 is elastically engaged with the screen hole 301, and the elastic telescopic rod 106 integrates the vibration structure of the cylindrical body 3, thereby preventing the powder from residual in the inner wall of the cylinder 3.

[0035] Reference image 3 The case 1 includes a support leg 101, a fixing plate 102, and a fixed bolt 103, and the box is we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com