Laser beam spot shape correcting method

A correction method, laser beam technology, applied in laser welding equipment, optics, condenser mirrors, etc., can solve the problem of time-consuming correction of spot shape, achieve the effect of suppressing man-hours and reducing mechanical errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

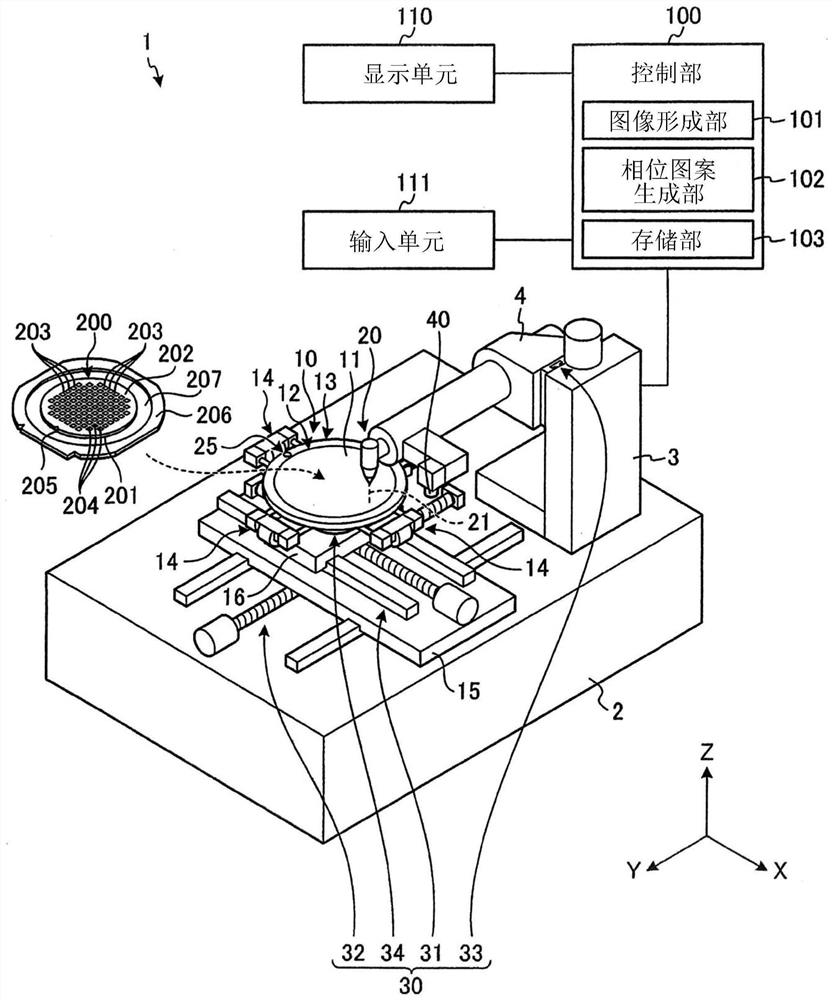

[0049] The method of correcting the spot shape of the laser beam according to the first embodiment of the present invention will be described with reference to the drawings. First, the configuration of the laser processing apparatus 1 for implementing the method of correcting the spot shape of the laser beam according to the first embodiment will be described. figure 1 It is a perspective view showing a configuration example of a laser processing apparatus implementing the method of correcting the spot shape of a laser beam according to the first embodiment. of the first embodiment figure 1 The illustrated laser processing apparatus 1 is an apparatus that irradiates a workpiece 200 with a pulsed laser beam 21 to perform laser processing on the workpiece 200 .

[0050] as figure 1 The workpiece 200 to be processed by the illustrated laser processing apparatus 1 is a wafer such as a disc-shaped semiconductor wafer or an optical device wafer having a substrate 201 of silicon, s...

no. 2 Embodiment approach 〕

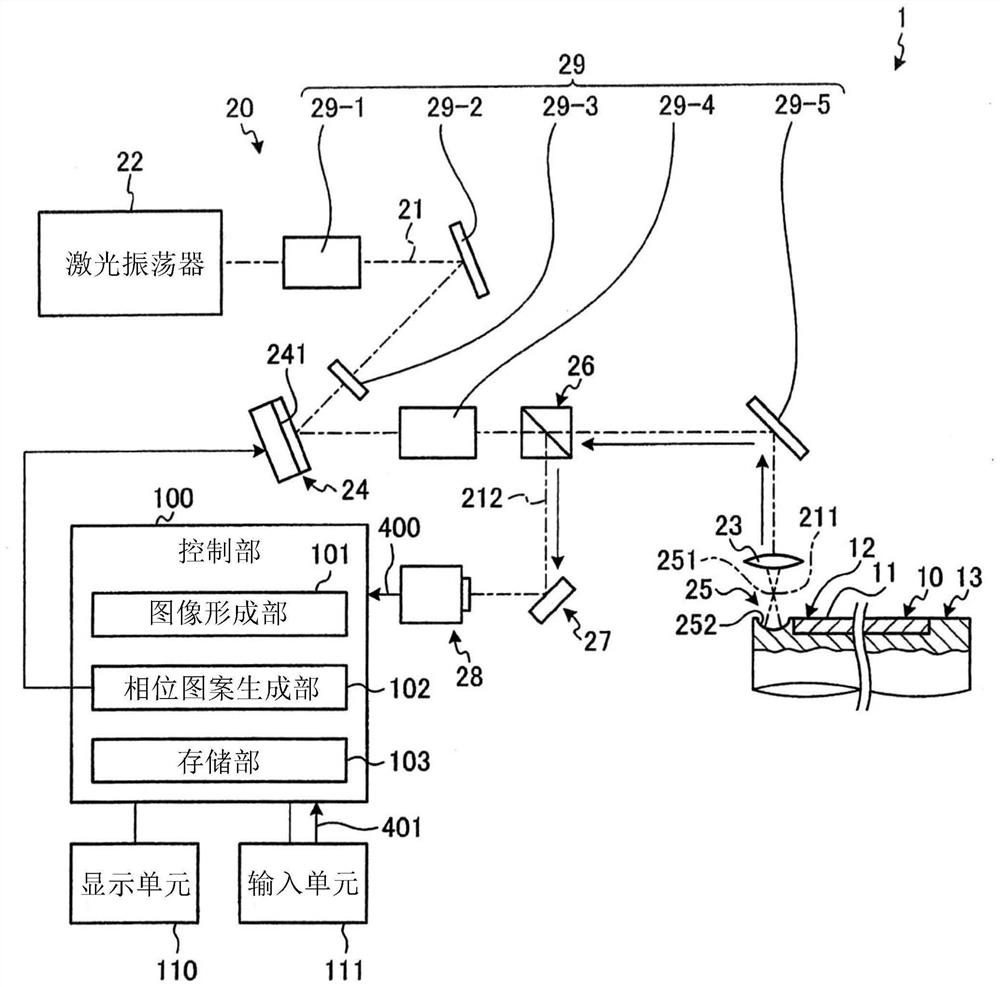

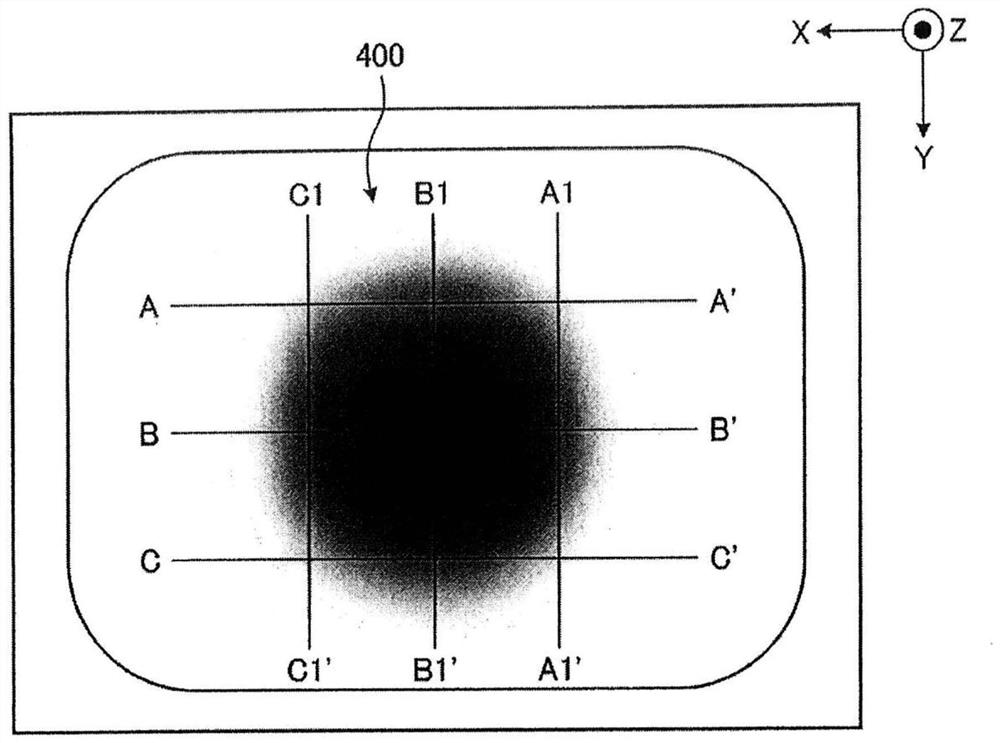

[0112] A method of correcting a spot shape of a laser beam according to a second embodiment of the present invention will be described with reference to the drawings. Figure 15 It is a perspective view showing a configuration example of a laser processing apparatus implementing the method of correcting the spot shape of a laser beam according to the second embodiment. Figure 16 is true Figure 15 A diagram illustrating the structure of the laser beam irradiation unit of the laser processing apparatus shown. In addition, in Figure 15 and Figure 16 In the description, the same reference numerals are attached to the same parts as those in the first embodiment, and description thereof will be omitted.

[0113] In addition to the functions of the image forming unit 101-2 and the storage unit 103-2, the laser processing apparatus 1-2 implementing the method of correcting the spot shape of the laser beam (hereinafter referred to as the correction method) according to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com