Preparation method of PE recycled plastic particles

A technology of recycled plastic granules and plastic rods, applied in the direction of manufacturing tools, welding equipment, aluminothermic welding equipment, etc., can solve the problems of continuous shearing, plastic granule quality degradation, and edge damage, so as to avoid finishing and improve efficiency , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of PE recycled plastic particles, comprising the steps of:

[0045] S1: Sorting and preliminarily cutting the recycled polyethylene plastic products, then cleaning the cut polyethylene plastic products, draining and drying the cleaned polyethylene plastic products;

[0046] S2: Put the dried polyethylene plastic product into a screw extruder for heating and melting, and the melted polyethylene latex will be extruded into a long strip from the end of the screw extruder;

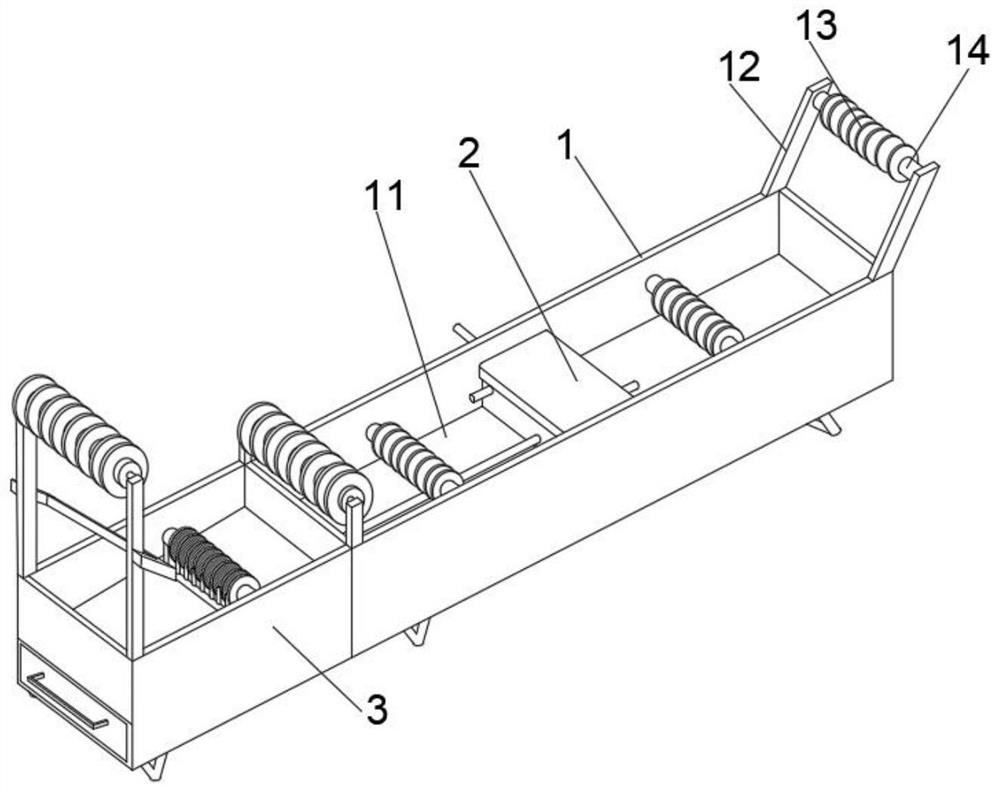

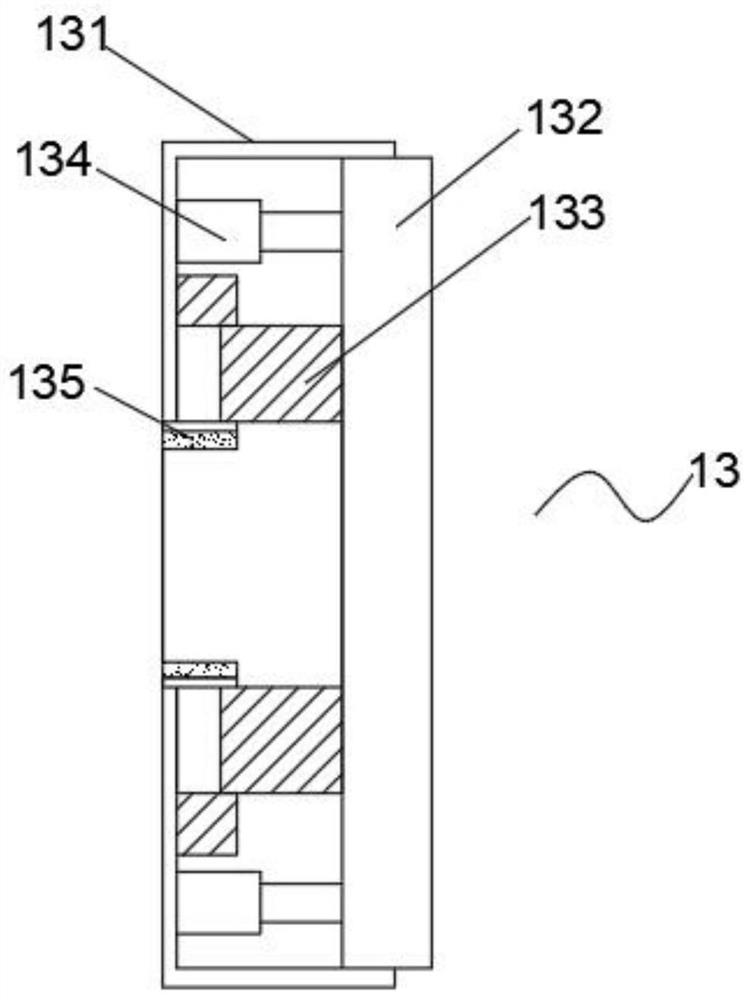

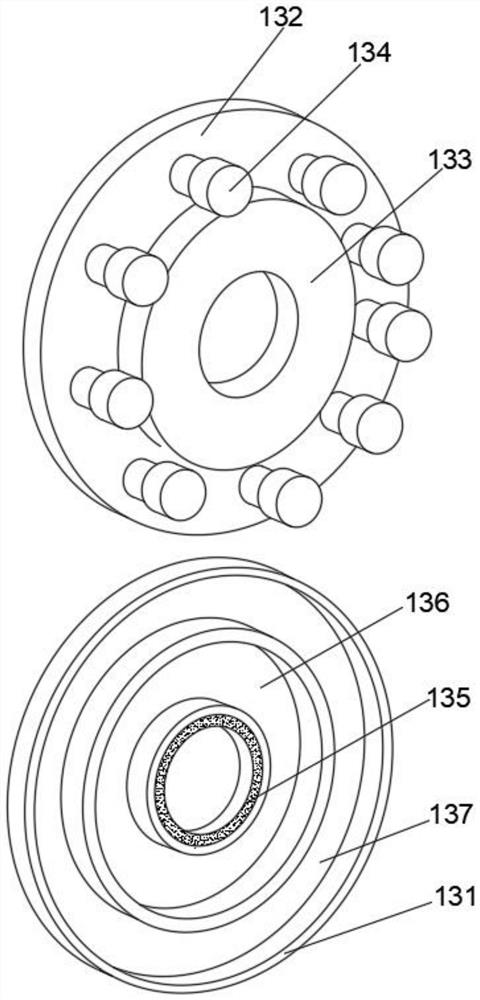

[0047] S3: the strip-shaped plastic rod is stretched and placed on the edge of the isolation plate 13 in the cooling and cleaning device, so that the isolation plate 13 isolates the plastic rods from each other, and along with the extrusion of the plastic rod, the plastic rod extends to the cooling tank 11 The interior is cooled and formed;

[0048] S4: The molded plastic rod enters the cleaning box 3, and is finally cleaned by the cleaner 35 inside the cleaning box 3. The cleaned ...

Embodiment approach

[0053]As an embodiment of the present invention, the detection mechanism 2 includes a cooling device 21, a sensor 22, a cover plate 23, and a second spring 24. The sensor 22 is located on the outer surface of the upper end of the cooling device 21. In the cleaning box 3, The connecting pipe 34 communicates with the cold water pipe 215, and the water flow enters the inside of the cleaning box 3 from the connecting pipe 34. Under the impact of the water flow, the solid particles on the sliding plate 33 can slide down into the storage box 38 and pass through the filter screen in the storage box 38. 36, so that the solid particles are intercepted inside the storage box 38, the water flows through the filter screen 36 through the drain port 39, and returns to the inside of the cooling tank 11. At this time, the washer 35 and the second spring 24 are all located outside the upper end of the cooling device 21 surface, and the number of sensors 22 and the second spring 24 are multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com