Metal quenching equipment for metal heat treatment

A technology for metal heat treatment and quenching equipment, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve the problems of general quenching uniformity and effect, difficult steel pipe anti-deflection positioning, and quenching end angle deviation, etc., to achieve positioning and clamping Good effect, improve service life, increase the effect of displacement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

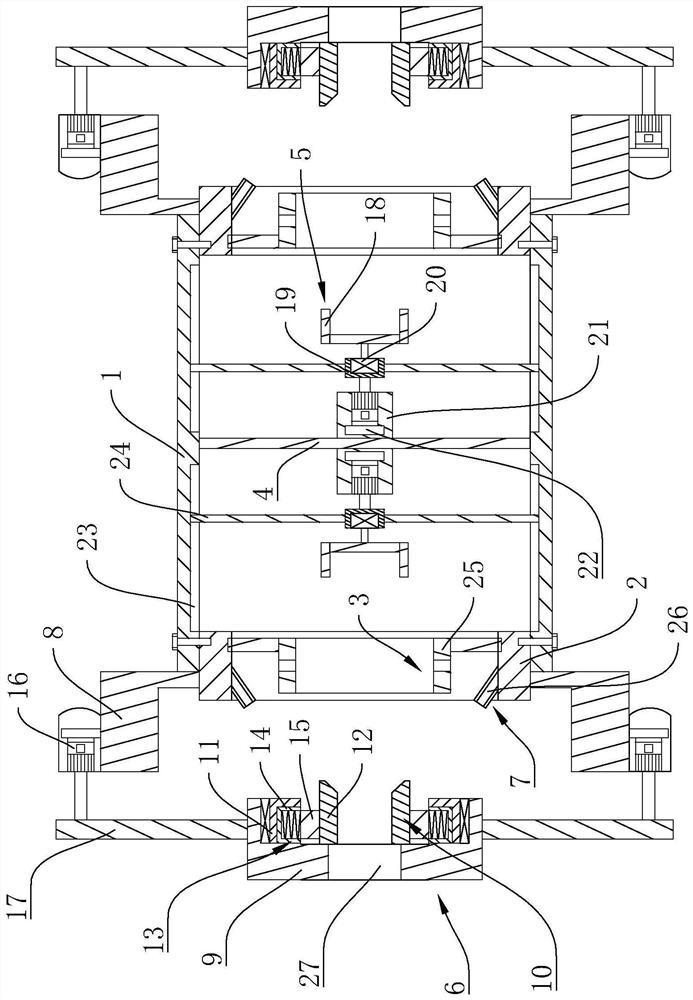

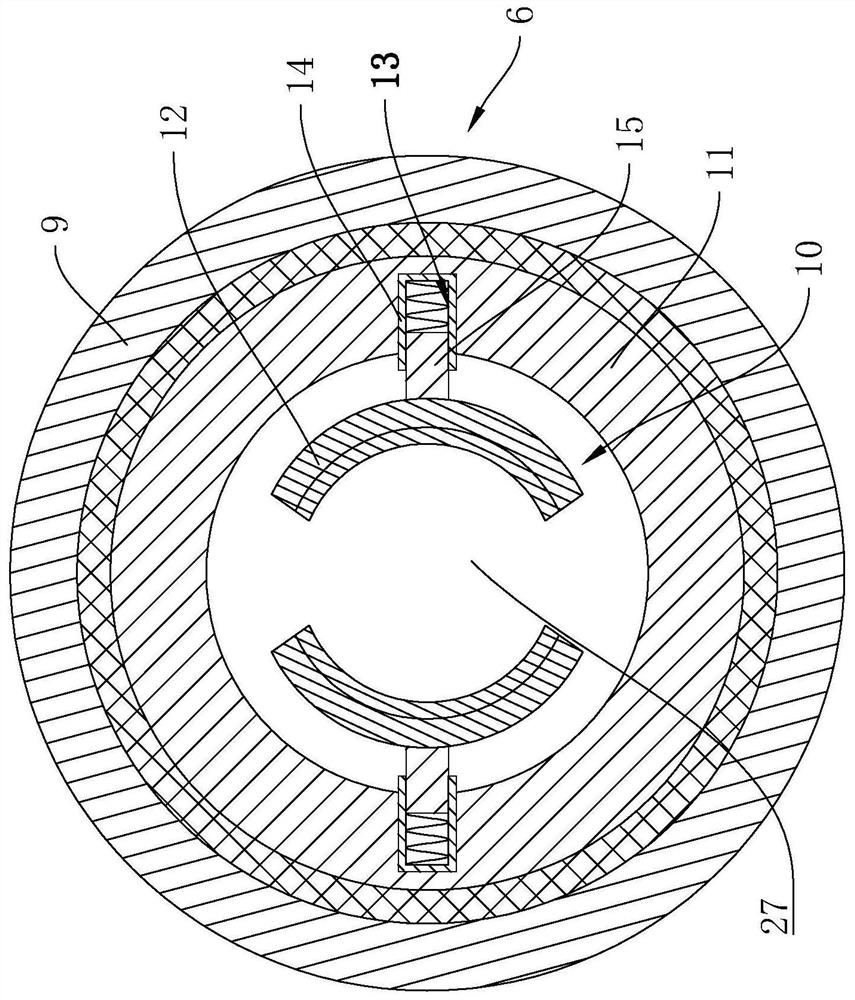

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 , figure 2 As shown, a metal quenching equipment for metal heat treatment includes a quenching base 1, and the quenching base 1 is provided with several quenching cooling seats 2 symmetrical along the center line of the quenching base 1, and the quenching cooling base 2 There is a metal induction hardening part 3 inside, and the quenching machine base 1 is also provided with a middle mounting plate 4, and the middle mounting plate 4 is provided with a number of metal clamping parts 5 symmetrical along the center line of the middle mounting plate 4 , the metal clamping part 5 can make a reciprocating linear motion along the end close to or away from the metal induction hardening part 3, and the end of the quenching cooling seat 2 far away from the metal clamping part 5 is provided with an elastic limit clamping assembly 6, so The above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com