Steel coil production time optimization calculation method in cold rolling process and application thereof

A production time and optimization calculation technology, applied in the field of cold-rolled strip steel, can solve the problem of low production time accuracy and achieve the effect of improving data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

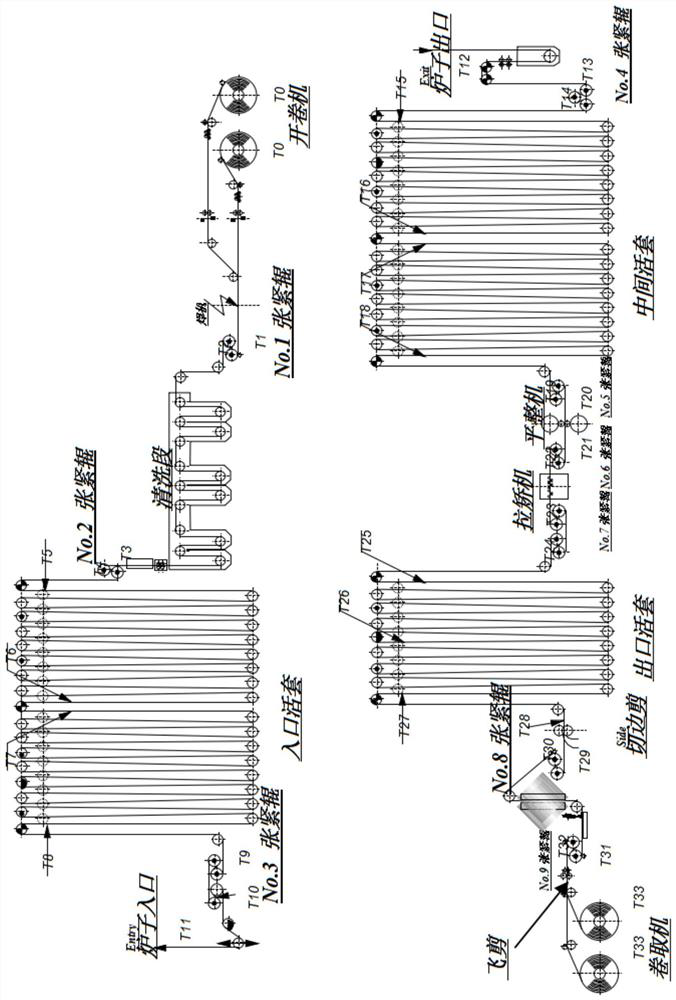

Image

Examples

Embodiment 1

[0046] This embodiment discloses a method for optimizing the production time of steel coils in the cold rolling process, including the following steps:

[0047] Step 1: The first-level electrical system obtains the production action time information of the steel coil; the acquired production action time information includes the welding time at the welding machine when the parent coil starts to go online and the shearing time at the flying shear when each sub-coil goes off the line.

[0048] In the prior art, the time when the master roll chilled roll is welded by the on-line welding machine is used as the start time of the first sub-roll of the parent roll in continuous unrolling, and the other sub-rolls of the parent roll are taken as the export fly-shearing split time as the last roll End time, start time of the next volume. This method has no calculation in the secondary control system (PCS), and the secondary system directly transmits the time data from the primary system ...

Embodiment 2

[0099] System stability check:

[0100] We have applied the new method model to run on the continuous annealing production line for 5 years. In August 2020, the production time for producing three continuous annealing sub-coils after continuous annealing is for a parent coil number S207165930 chilled coil:

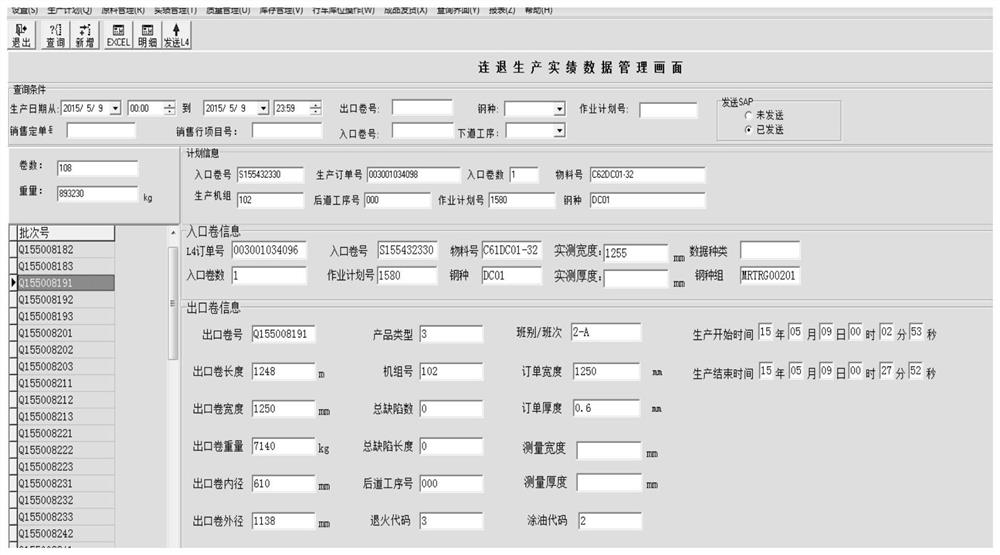

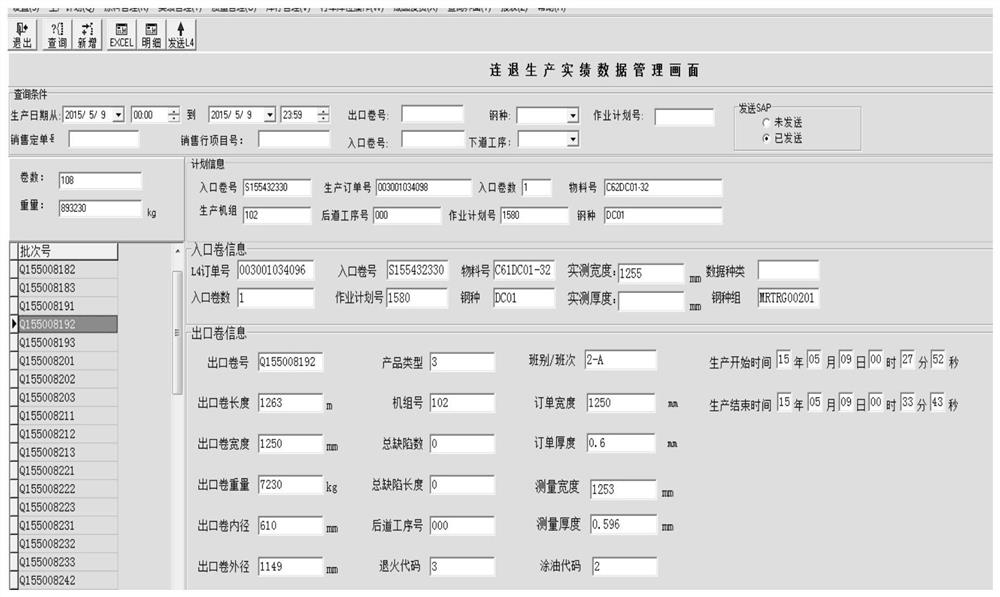

[0101] The first continuous retreat sub-volume, volume number: J208002691, see the production time Figure 10 As shown, the production start time: 21:57:47 on August 6, 2020, and the production end time: 22:23:01 on August 6, 2020;

[0102] The second continuous retreat sub-volume, volume number: J208002692, see the production time Figure 11 As shown, the production start time: 22:03:17 on August 6, 2020, and the production end time: 22:30:15 on August 6, 2020;

[0103] The third consecutive retreat sub-volume, volume number: J208002693, see the production time Figure 12 As shown, the production start time: 22:11:31 on August 6, 2020, and the production end time: 22:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com