A fiber laser processing head and cladding plate technology

A fiber laser and processing head technology, applied in metal material coating process, coating, etc., can solve problems such as laser failure, burning of laser core components, etc., achieve high energy bearing capacity, improve service quality and life, and enhance the overall The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

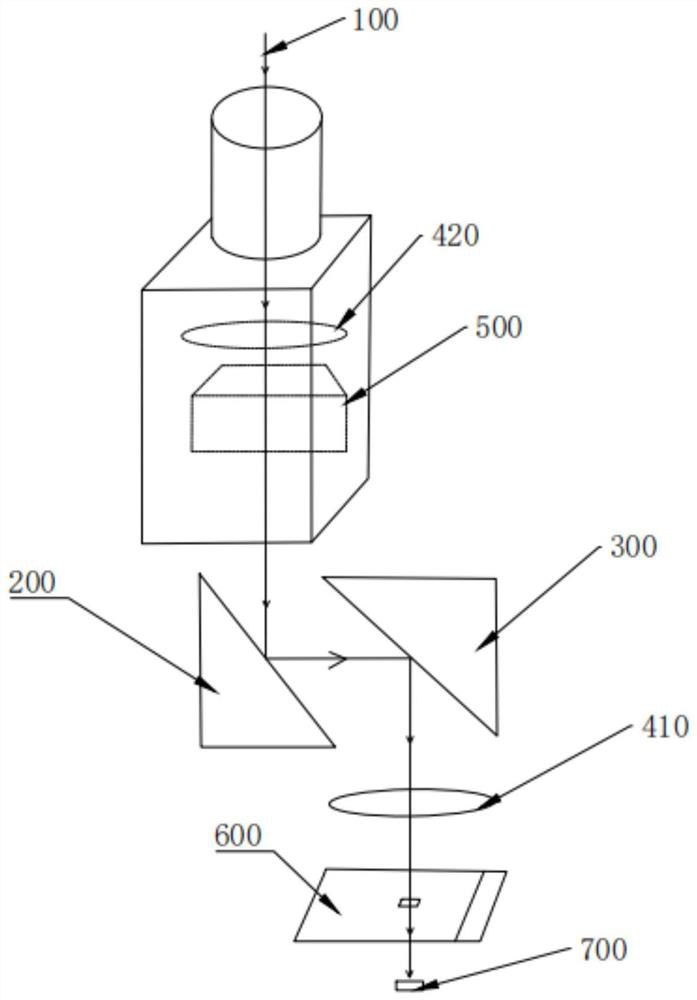

[0024] A fiber laser processing head, such as figure 1 As shown, it includes sequentially setting a collimating integrator 200, a focusing integrator 300 and a first protective mirror 410 along the emission optical path of the laser beam 100. The laser beam 100 enters the collimating integrator 200 vertically and then enters the focusing integrator 300 horizontally. Then enter the first protective mirror 410 vertically, and the collimating integrator 200 and the focusing integrator 300 are both copper integrator mirrors. The fiber laser is the main equipment for generating the laser beam 100 for processing; the processing head is a beam shaping structure, which can shape the divergent laser beam 100 generated by the fiber laser into various light spots 700 to meet the processing needs. The processing head is matched with the fiber laser Used to meet the requirements of laser cladding on different sheets. The copper integrator is used for collimation and focusing. The copper i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com