Drum-type coffee surface water air dryer

A drum type, coffee technology, applied in the fields of application, food processing, food science, etc., can solve the problems that affect the economic benefits of enterprises, the high cost of coffee production, high energy consumption, etc., and achieve the advantages of mechanization, shortening of processing time, and air-drying high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

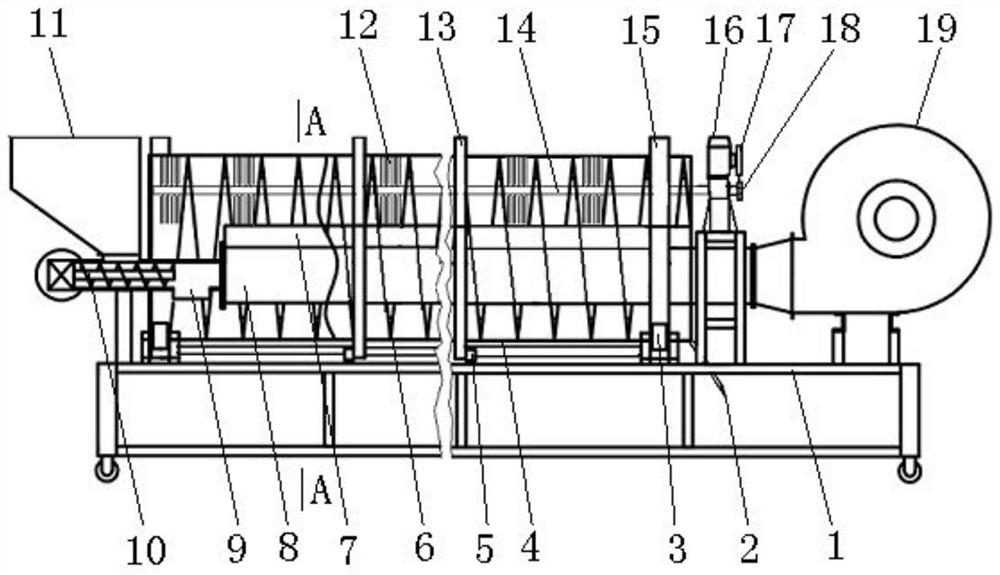

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

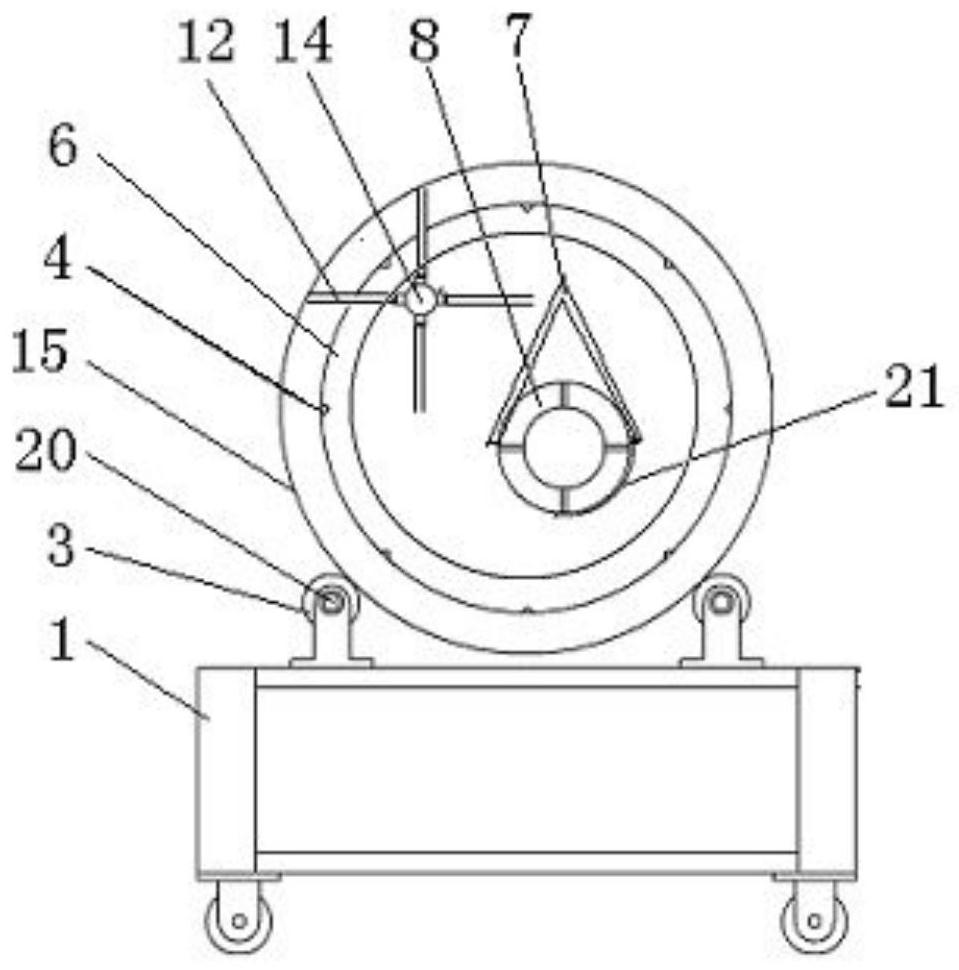

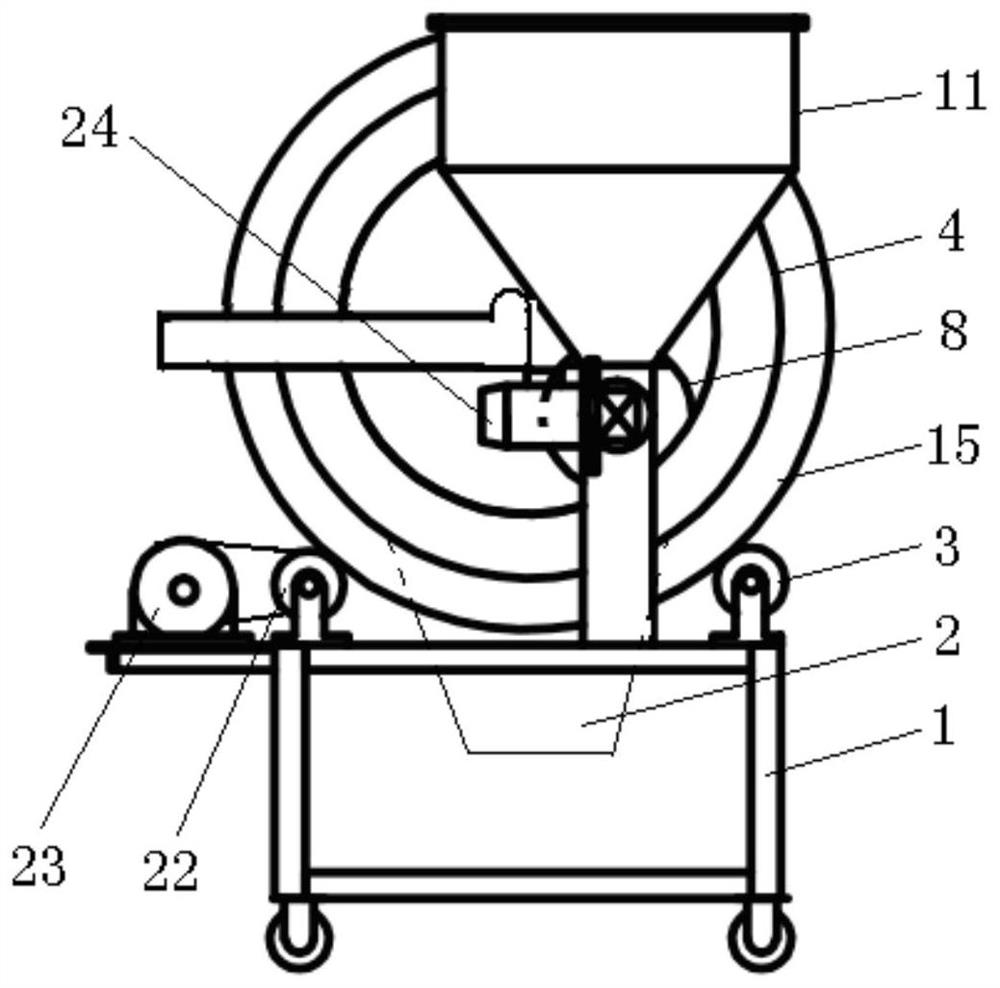

[0019] The drum-type coffee table water air dryer provided by the present invention comprises a frame 1, which is placed on the frame 1 with a feed port 9 and a discharge port 2, and a cavity is arranged in it, and a screw pusher is arranged in the cavity. The rotating drum 4 of the plate 6, wherein: the first mesh wall is set on the rotating drum 4, and the air duct 8 connected with the air source 19 is arranged in the cavity of the rotating drum 4, and the second mesh wall 21 is arranged on the air duct 8 ;

[0020] The first mesh wall provided on the rotating drum 4 is distributed on the entire cylinder wall, so that the material entering the cavity of the rotating drum 4 can volatilize the surface water as soon as possible through the first mesh wall;

[0021] The second mesh wall 21 provided on the air duct 8 is a local setting, specifically arranged on the 1 / 4 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com