High-energy ionic chemical organic and inorganic waste gas purification device

An exhaust gas purification device and high-energy ion technology, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as single stirring, substandard waste, and environmental pollution, so as to improve the mixing effect, improve practicability, The effect of good evolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

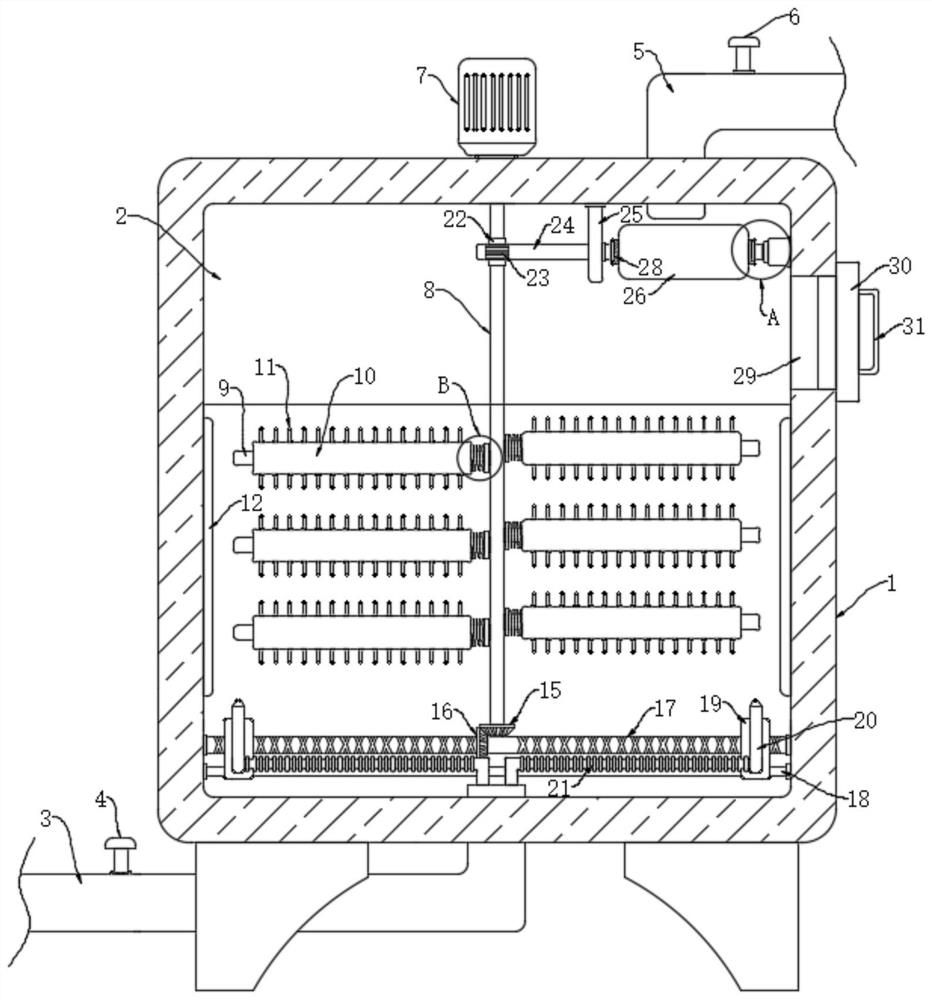

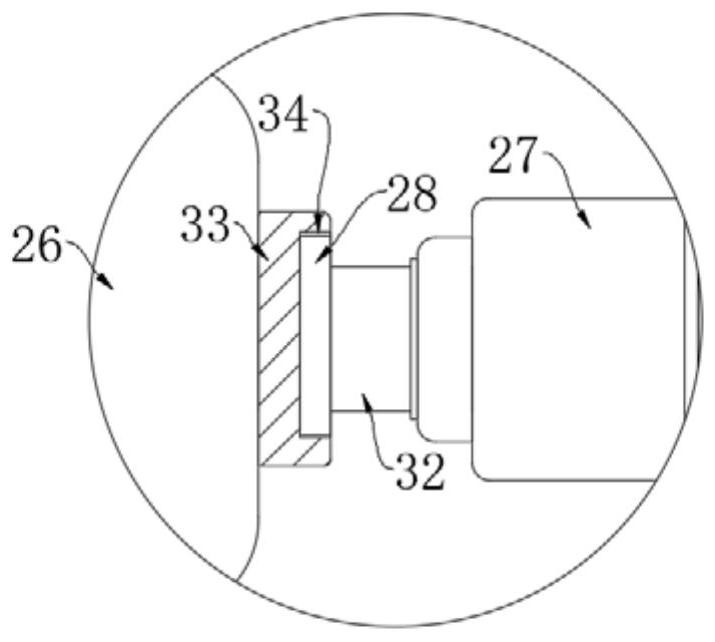

[0022] Refer Figure 1-5 A high energy ion chemical organic inorganic exhaust gas purification device, including the housing 1, the housing 1 is provided with a mounting chamber 2, and the mounting chamber 2 is placed in a liquid absorbed harmful gas, and the left side of the housing 1 is provided with an air passage. 3, the right end of the intake passage 3 is in communication with the bottom space of the mounting chamber 2, and the first valve 4 is mounted on the air passage 3, and the first valve 4 is used to open and close the gas passage 3, the right side of the housing 1. An air passage 5 is provided, and the left end of the air passage 5 is in communication with the top space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com