Utilization method of industrial red mud waste powder

A technology of waste powder and red mud, which is applied in the field of red mud ceramics, can solve the problems of red mud occupying storage space and consuming manpower and material resources, and achieve the effects of avoiding waste of manpower and material resources, avoiding pollution, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

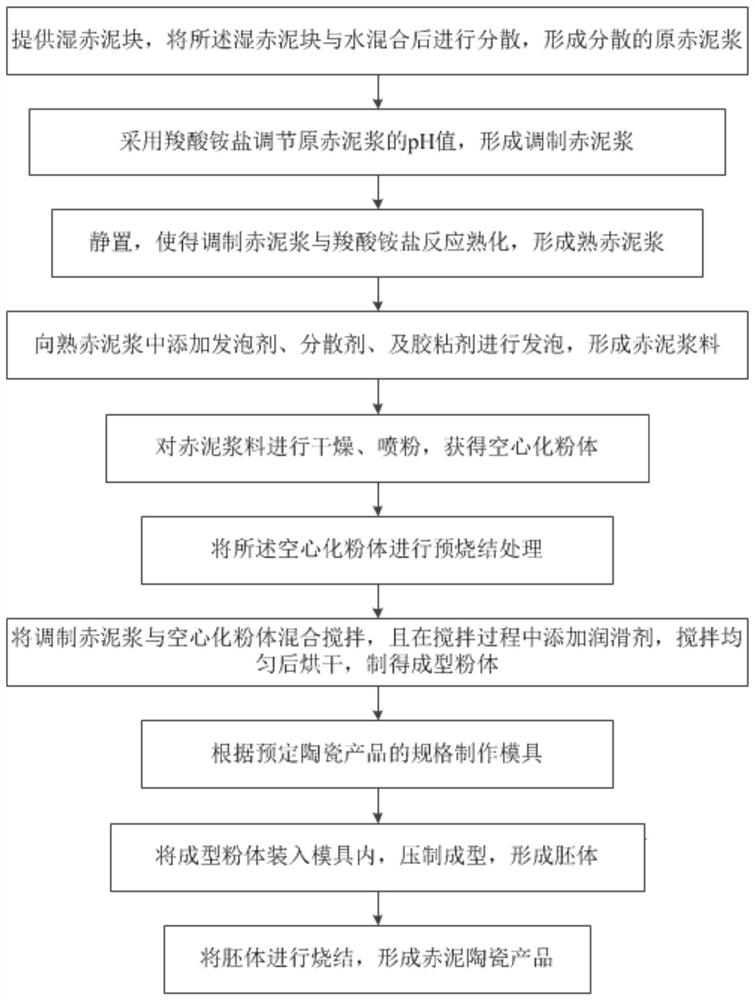

Method used

Image

Examples

Embodiment 1

[0045] A method for utilizing industrial red mud waste powder, comprising the steps of:

[0046] Step 1: providing wet red mud lumps, mixing the wet red mud lumps with water and then dispersing to form dispersed raw red mud slurry; the weight ratio of the wet red mud lumps to water is 1:1; the wet red mud lumps The particle size of the powder is below 200 nanometers;

[0047] Step 2: Use carboxylate ammonium salt to adjust the original red mud slurry with a pH value of 9-12, so that the pH value of the original red mud slurry is 8.5 to form a modulated red mud slurry; this step can increase the cohesiveness of the red mud powder, And in the follow-up process, the sintering activity of the red mud powder and the strength of the green body formed by the red mud powder can be improved;

[0048] Step 3: Leave the prepared red mud slurry at room temperature for 68 hours in the sedimentation tank, so that the prepared red mud slurry and carboxylate ammonium salt are fully soaked, r...

Embodiment 2

[0057] A method for utilizing industrial red mud waste powder, comprising the steps of:

[0058] Step 1: Provide wet red mud lumps, mix the wet red mud lumps with water and disperse to form dispersed raw red mud slurry; the weight ratio of the wet red mud lumps to water is 0.5:1; wet red mud lumps The particle size of the powder is below 200 nanometers;

[0059] Step 2: Use carboxylate ammonium salt to adjust the original red mud slurry with a pH value of 9-12, so that the pH value of the original red mud slurry is 7.5 to form a modulated red mud slurry; this step can increase the cohesiveness of the red mud powder, And in the follow-up process, the sintering activity of the red mud powder and the strength of the green body formed by the red mud powder can be improved;

[0060] Step 3: Put the prepared red mud slurry at room temperature for 72 hours in the sedimentation tank, so that the prepared red mud slurry and carboxylate ammonium salt are fully soaked, reacted and matur...

Embodiment 3

[0069] A method for utilizing industrial red mud waste powder, comprising the steps of:

[0070] Step 1: Provide wet red mud lumps, mix the wet red mud lumps with water and disperse to form dispersed raw red mud slurry; the weight ratio of the wet red mud lumps to water is 0.8:1; wet red mud lumps The particle size of the powder is below 200 nanometers;

[0071] Step 2: Use carboxylate ammonium salt to adjust the original red mud slurry with a pH value of 9-12, so that the pH value of the original red mud slurry is 8 to form a modulated red mud slurry; this step can increase the cohesiveness of the red mud powder, And in the follow-up process, the sintering activity of the red mud powder and the strength of the green body formed by the red mud powder can be improved;

[0072] Step 3: Put the prepared red mud slurry at room temperature for 60 hours in the sedimentation tank, so that the prepared red mud slurry and carboxylate ammonium salt are fully soaked, reacted and matured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com