High-gloss polyvinyl chloride resin composition as well as preparation method and application thereof

A technology of polyvinyl chloride resin and high-density polyethylene, which is applied in the field of high-gloss polyvinyl chloride resin composition and its preparation, can solve the problems of uneven plasticization, poor mechanical properties, and low gloss, and achieve improved gloss , Improve plasticization and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

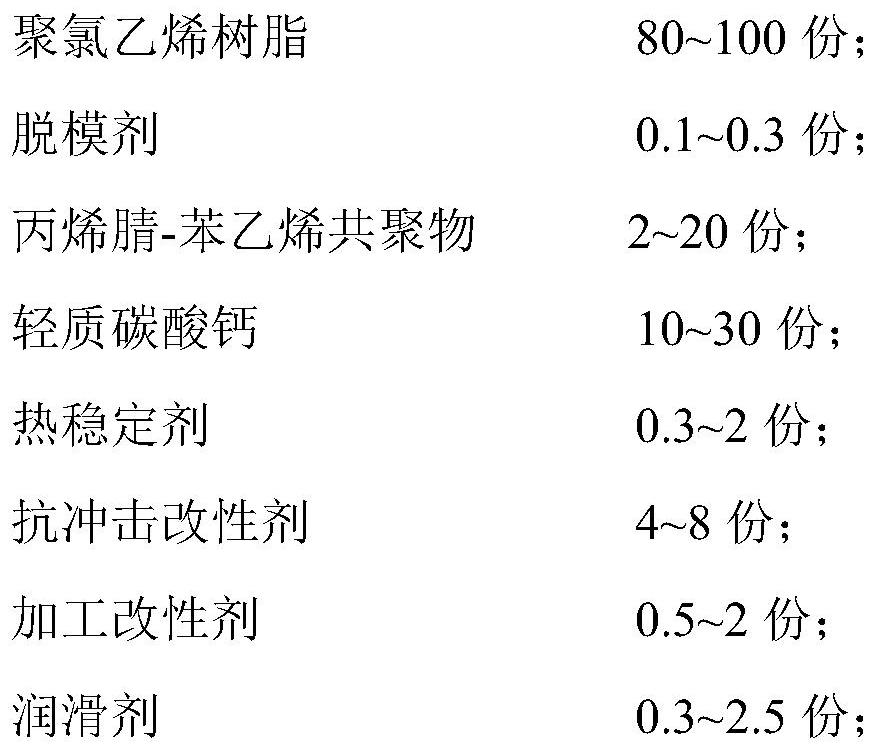

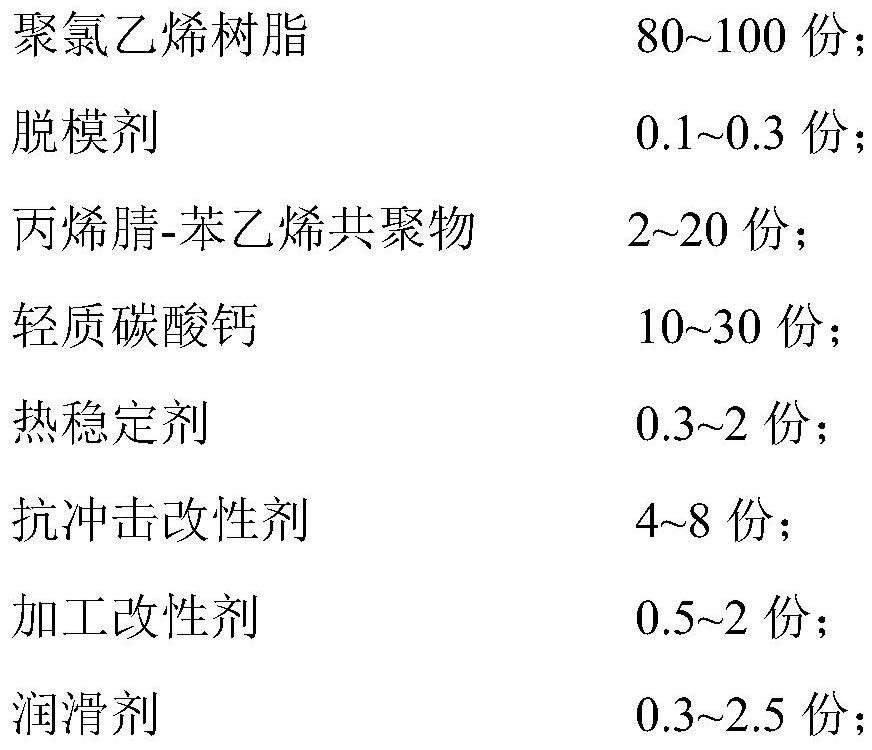

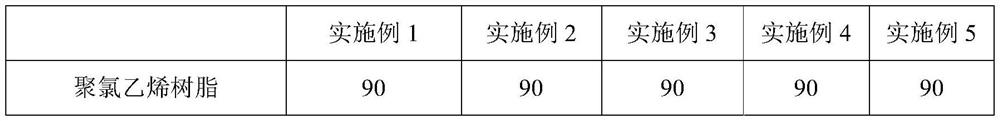

[0056] The formula (part) of table 1 embodiment 1~5

[0057]

[0058]

Embodiment 6~10

[0060]The formula (part) of table 2 embodiment 6~10

[0061] Example 6 Example 7 Example 8 Example 9 Example 10 PVC resin 90 90 90 80 100 Release agent A 0.2 0.2 0.2 0.1 0.3 Acrylonitrile-styrene copolymer C — — — 2 10 Acrylonitrile-styrene copolymer B 8 — — — — Acrylonitrile-styrene copolymer D — 8 — — — Acrylonitrile-styrene copolymer E — — 8 — — light calcium carbonate 15 15 15 30 10 Heat stabilizers 1 1 1 2 0.3 impact modifier 6 6 6 8 4 Processing Modifier 1 1 1 2 0.5 lubricant 1.8 1.8 1.8 2.5 0.3

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com