Fishhook production process for improving surface brightness of fishhook

A technology of production process and surface brightness, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as inability to ensure, achieve the effect of ensuring anti-corrosion, attracting fish, and improving success

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

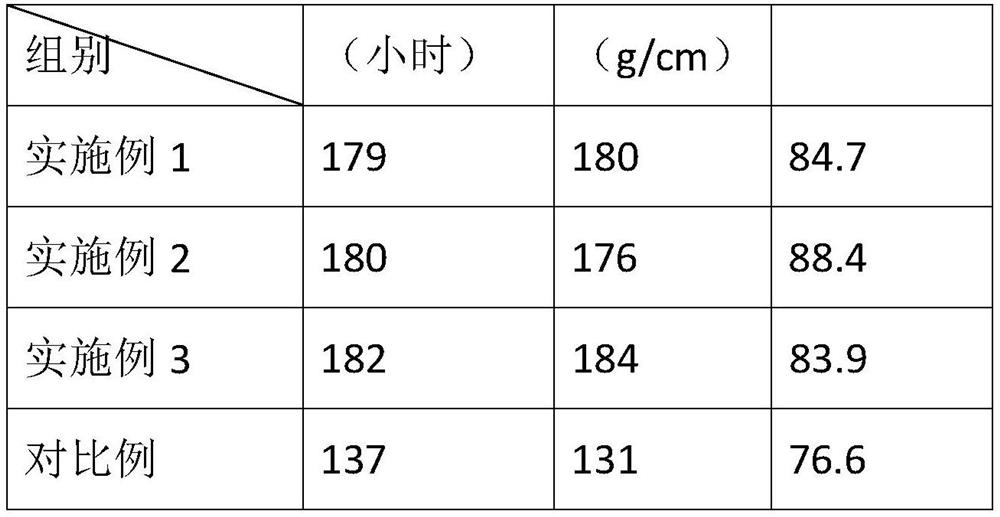

Embodiment 1

[0020] A fishhook production process for improving the surface brightness of the fishhook, comprising the following steps:

[0021] S1: cleaning the fishhook to be treated;

[0022] S2: Nickel plating is carried out on fishhooks, and each liter of electroplating solution contains 180g of nickel sulfate, 40g of nickel chloride, and 35g of boric acid; the electroplating time is 30 minutes;

[0023] S3: The metal element that has a brightening effect on the nickel-plated fishhook electroplating, the metal element is silver or tin; when the metal element is silver, each liter of electroplating solution contains 100g of potassium chloride, 3g of potassium silver cyanide, Plating time is 1 minute;

[0024] S4: Electrophoresis is used to plate colored paint on fishhooks.

Embodiment 2

[0026] A fishhook production process for improving the surface brightness of the fishhook, comprising the following steps:

[0027] S1: Ultrasonic cleaning of the hooks to be treated;

[0028] S2: carry out nickel plating to fishhook, contain nickel sulfate 253g, nickel chloride 50g, boric acid 45g in every liter of electroplating solution; Electroplating time is 46 minutes;

[0029] S3: Metal elements that have a brightening effect on nickel-plated fishhook electroplating, the metal elements are silver or tin; when the metal elements are silver, each liter of electroplating solution contains 130g of potassium chloride, 8g of potassium silver cyanide, Plating time is 2 minutes;

[0030] S4: Electrophoresis is used to plate colored paint on fishhooks.

Embodiment 3

[0032] A fishhook production process for improving the surface brightness of the fishhook, comprising the following steps:

[0033] S1: Ultrasonic cleaning of the hooks to be treated;

[0034] S2: Nickel plating is carried out on fishhooks, and each liter of electroplating solution contains 280g of nickel sulfate, 60g of nickel chloride, and 50g of boric acid; the electroplating time is 70 minutes;

[0035] S3: The metal element that has a brightening effect on the nickel-plated fishhook electroplating, the metal element is silver or tin; when the metal element is silver, each liter of electroplating solution contains 150g of potassium chloride and 15g of potassium silver cyanide; Plating time is 3 minutes;

[0036] S4: Electrophoresis is used to plate colored paint on fishhooks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com