Steam heat energy recovery system

A recovery system, a technology of steam heat energy, applied in steam generation, preheating, heat exchangers, etc., can solve the problems of large heat loss, waste of steam resources, single reuse direction, etc., and achieve the effect of improving efficiency and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

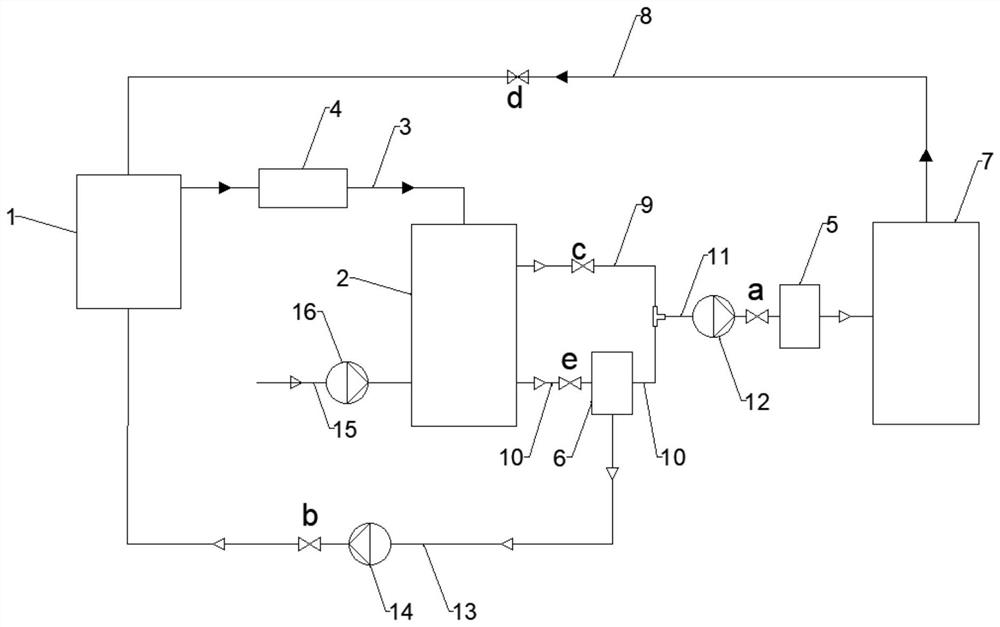

[0035] The technical scheme that the present invention adopts is as follows:

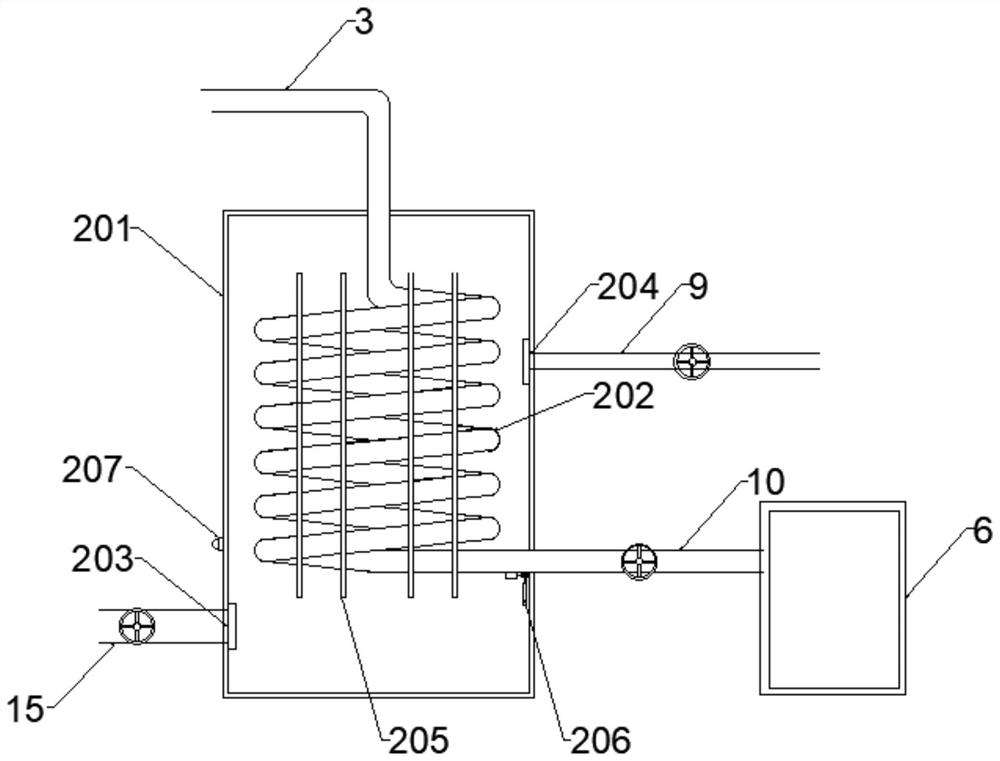

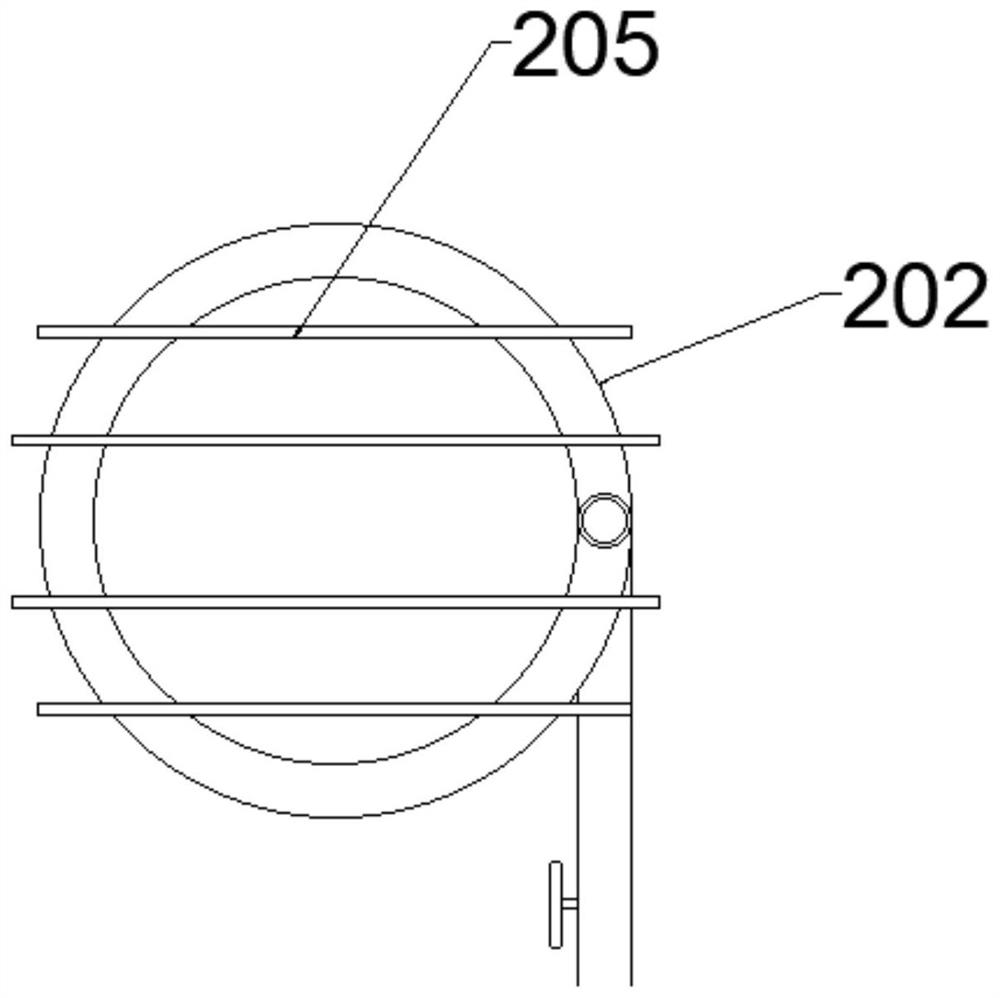

[0036]A steam heat energy recovery system, including production equipment 1 using high-temperature steam as a heat source; a heat exchanger 2 for condensing high-temperature steam, and a high-temperature steam inlet is arranged on the top of the heat exchanger 2, and the high-temperature steam inlet is connected with the production equipment 1 is connected by a steam pipe 3, the lower part of the side wall of the heat exchanger 2 is provided with a hot water outlet correspondingly, and the hot water outlet is connected to a second high-temperature water pipe 10, and the heat exchanger 2 is also provided with a cooling water inlet 203 and a cooling water outlet 204, the cooling water inlet 203 communicates with the cooling water inlet pipe 15, the cooling water pump 16 on the cooling water inlet pipe 15, the cooling water outlet 204 communicates with the first high temperature water pipe 9, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com