Variable-attack-angle free surface cutting hydrofoil experiment model

An experimental model and variable attack angle technology, applied in the field of marine ships, can solve the problems of high cost, poor reliability, large impact force, etc., and achieve the effects of low cost, easy disassembly and movement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

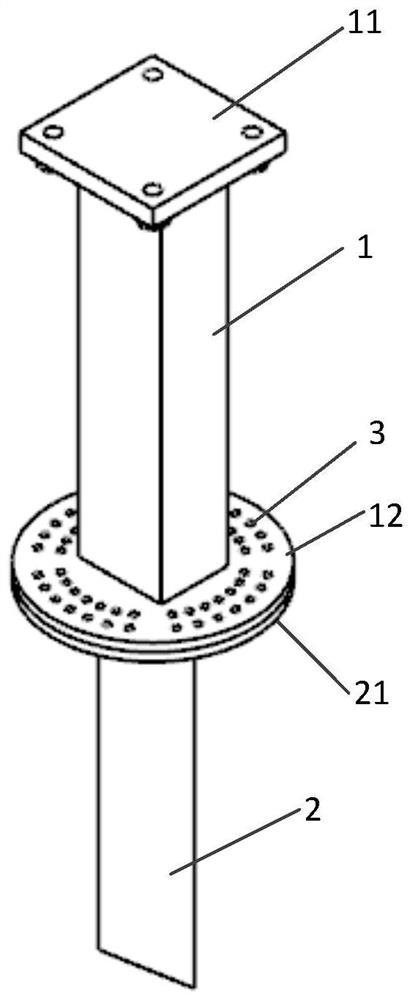

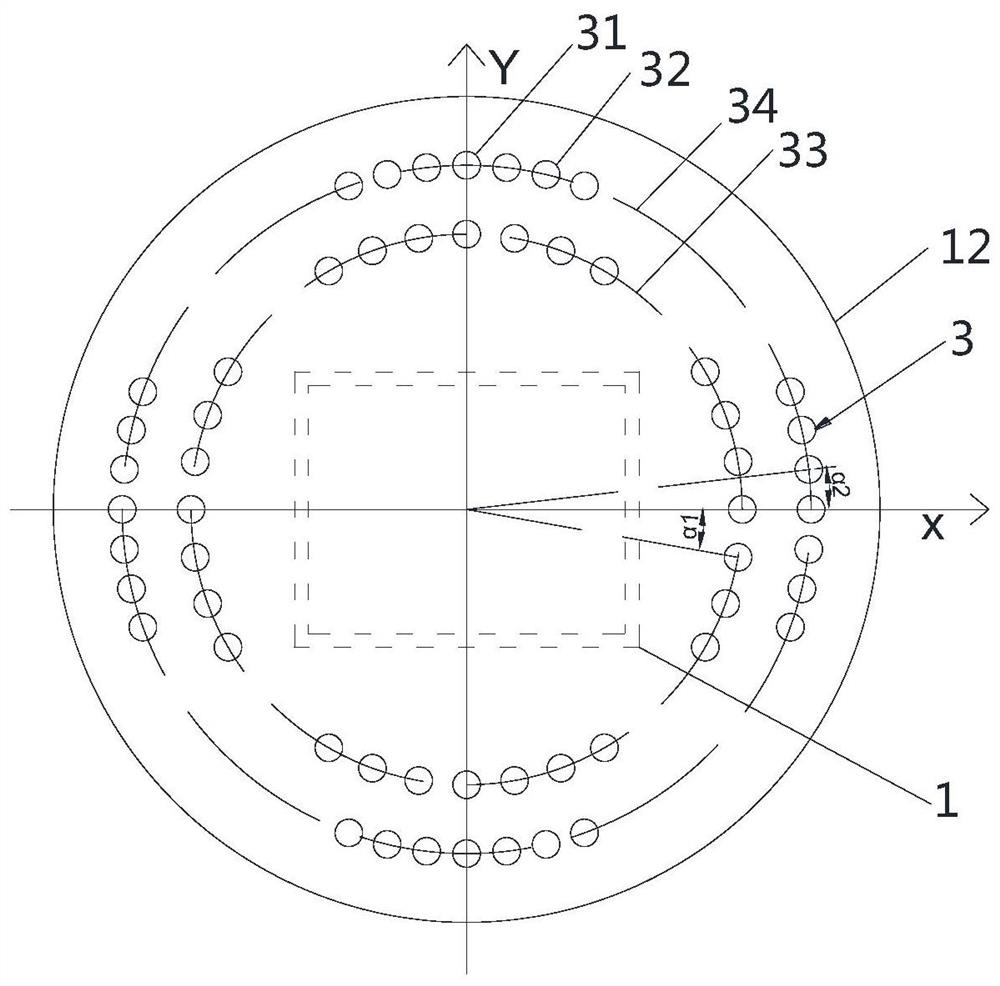

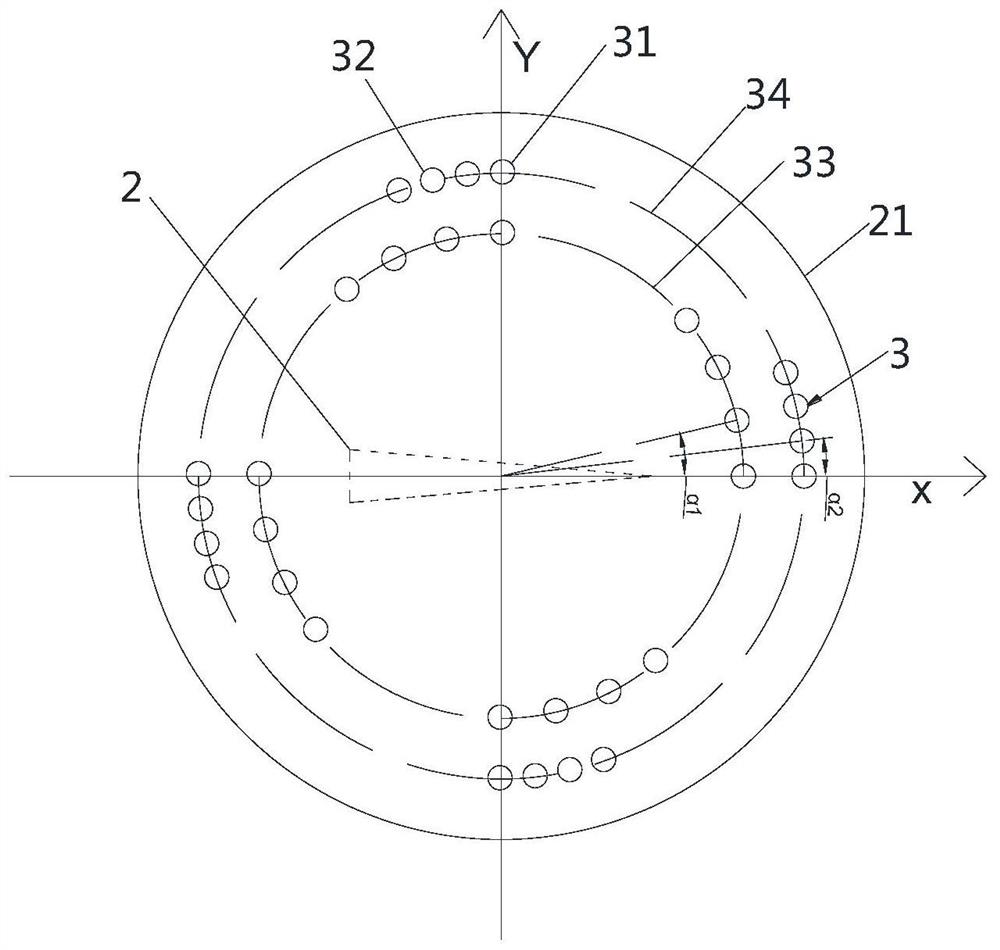

[0033]The connecting plate 11 on the support rod 1 is a rectangular steel plate with a thickness of 5mm and an area of 80mm*80mm. The screw hole is 8.2mm in diameter and is located at the corner of the steel plate 15mm away from each side. Rectangular steel pipe, the length of the steel pipe is 400mm; the support disc 12 is a circular steel plate with a thickness of 5mm, and the radius of the circular steel plate is 60mm. Y-axis) and small circle intersect (40mm places on the four vertical directions from the center of the circle) to open positioning hole 31, and the size of positioning hole 31 is 4mm in diameter, then counterclockwise and clockwise respectively open the attack angle hole (10 degree) every 10 degrees Representing the angle of attack every time the angle is adjusted), 3 holes for the angle of attack are opened counterclockwise and clockwise; (2) The great circle has a radius of 50mm, at the intersection of the central symmetry axis (X axis and Y axis) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com