An automatic polishing device and its working method

A polishing device and workbench technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problem that the width and height cannot be adjusted flexibly, and achieve the effect of improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

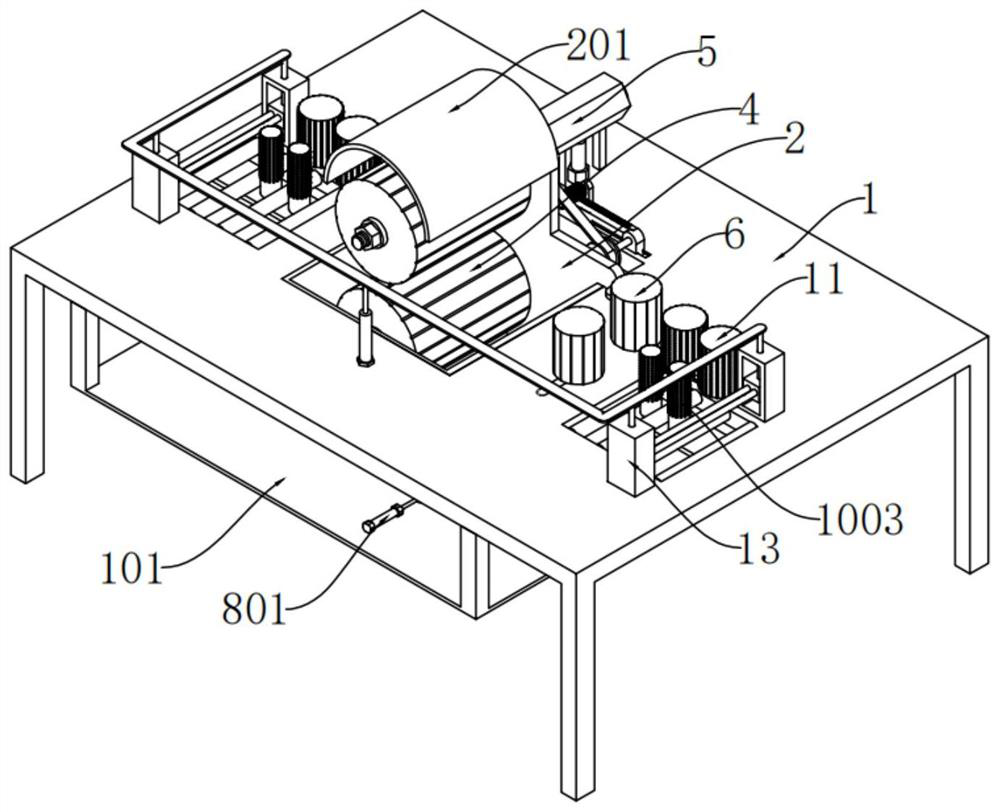

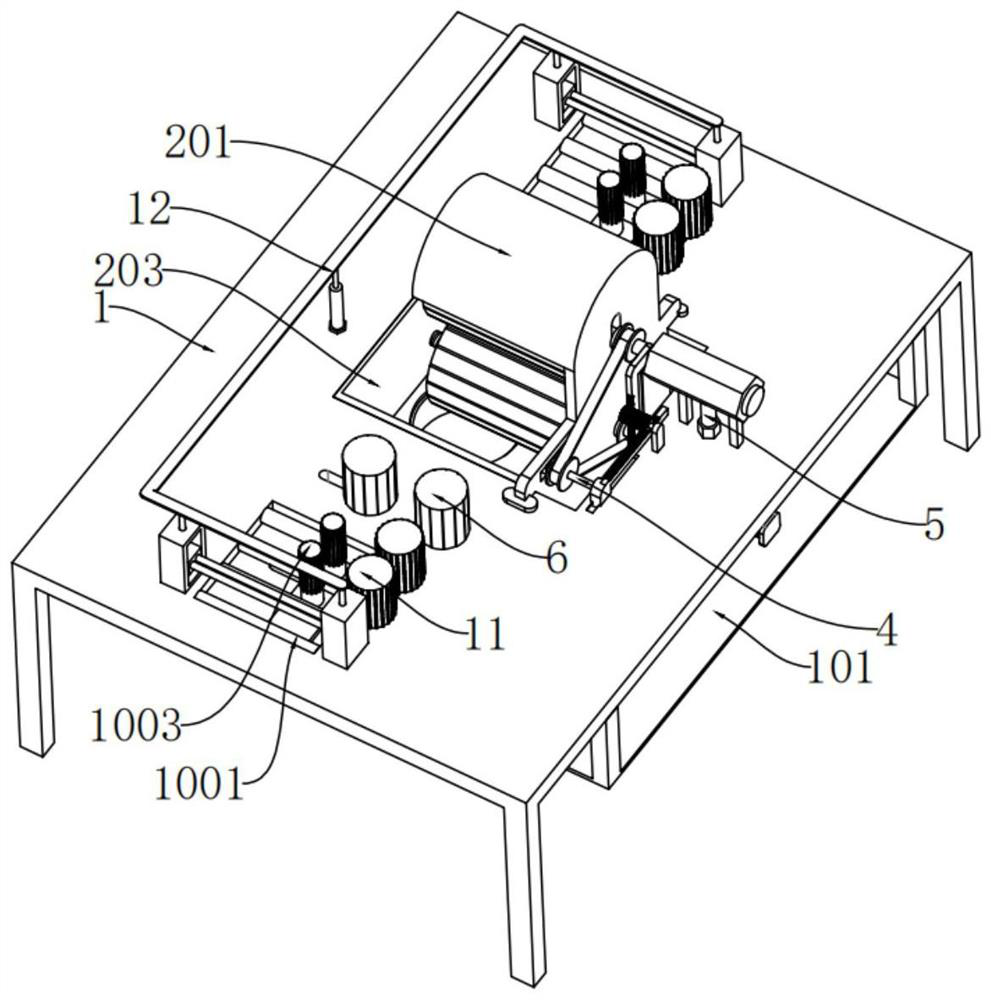

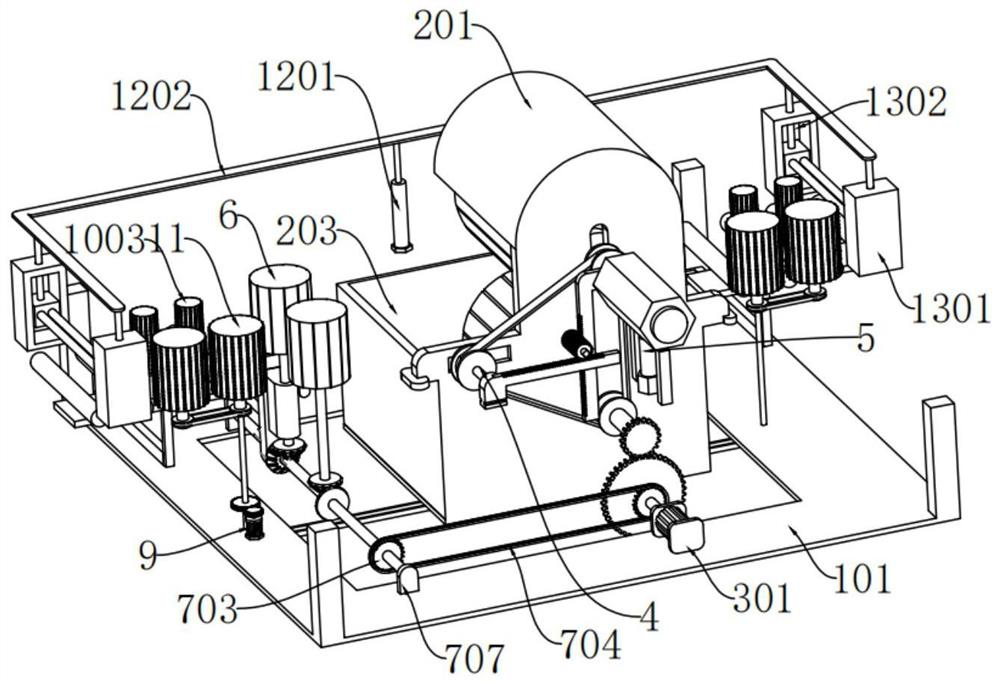

[0048] see Figure 1-15 , the technical solution provided by this embodiment is as follows:

[0049] An automatic polishing device and its working method, comprising a workbench 1, the lower end of the workbench 1 is fixedly connected with an auxiliary frame 101, and the upper end of the workbench 1 is provided with a polishing groove 102, a sixth chute 604 and two third installation grooves 10 and the first mounting groove 103, the polishing groove 102 is fixedly connected with the protective frame 2, the upper end of the protective frame 2 is fixedly connected with the protective cover 201, the rear end of the protective frame 2 is provided with the first chute 202, and the lower end of the protective frame 2 A receiving hopper 203 is fixedly connected, and the lower end of the receiving hopper 203 is provided with a feed opening 204. A front polishing mechanism 4 is arranged in the protective frame 2. The front polishing mechanism 4 includes two large polishing rollers 401 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com