Antibacterial and antistatic ceramic tile preparation method

An anti-static, ceramic tile technology, applied in the field of ceramic tiles, can solve the problems of poor polishing effect, adverse effect of polishing and polishing, and easy residue of debris, etc., to achieve the effect of reducing debris, improving the effect of polishing and polishing, and uniform polishing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0038] Such as figure 1 As shown, the present embodiment provides a method for preparing antibacterial and antistatic ceramic tiles, comprising the following steps:

[0039] Step 1. Raw material treatment: mix clay and sand, add water and grind them into fine particles, and then dry the fine particles. The powder is obtained by mixing the inorganic antibacterial agent and the antistatic functional powder with the dried fine particles.

[0040] Step 2. Pressing and sintering: the powder is pressed into shape and then sintered. After sintering, it is naturally cooled to obtain a shaped brick body.

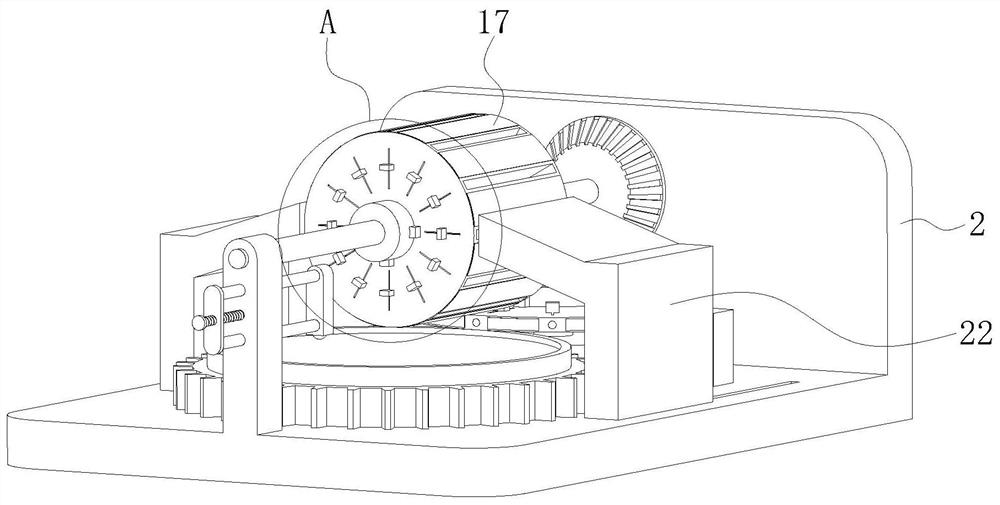

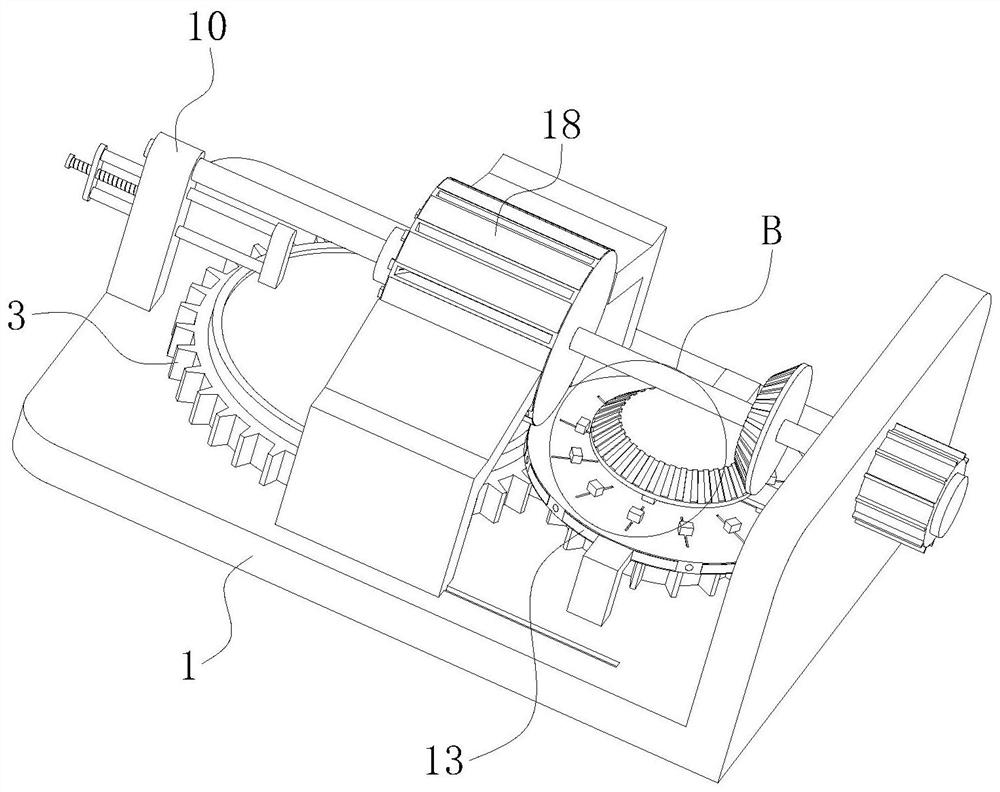

[0041] Step 3. Glazing and polishing: apply a glaze layer on the surface of the formed brick body, send the formed brick body coated with the glaze laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com