A manufacturing process of wellhead seal for oil extraction machine

A manufacturing process and technology of seals, applied in the field of wellhead seals manufacturing process, can solve problems such as low service life, seal manufacturing process cannot meet the production and processing requirements of high-performance seals, seals are easily damaged, and achieve manufacturing efficiency High, excellent compression and shock resistance, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, a manufacturing process for a wellhead seal for an oil extraction machine is proposed, which includes the following steps:

[0039] 1): The annular sheet is punched into a skeleton with a semicircular groove-shaped cross-section by a stamping process;

[0040] 2): adopt the casting moulding process to prepare the annular intermediate body with a circular cross-section;

[0041] 3): Use a pressing mechanism to relatively press the semi-circular grooves of the two skeletons to the annular intermediate body to make the intermediate skeleton;

[0042] 4): place the intermediate skeleton in the mold, and use injection molding to make a transition piece wrapped with rubber;

[0043] 5): A ring-shaped reinforcing rib is formed around the transition piece, and a synthetic wire is wound on the annular reinforcing rib along the circumference of the transition piece;

[0044] 6): Finally, the transition piece is placed in a mold, and injection molding is used...

Embodiment 2

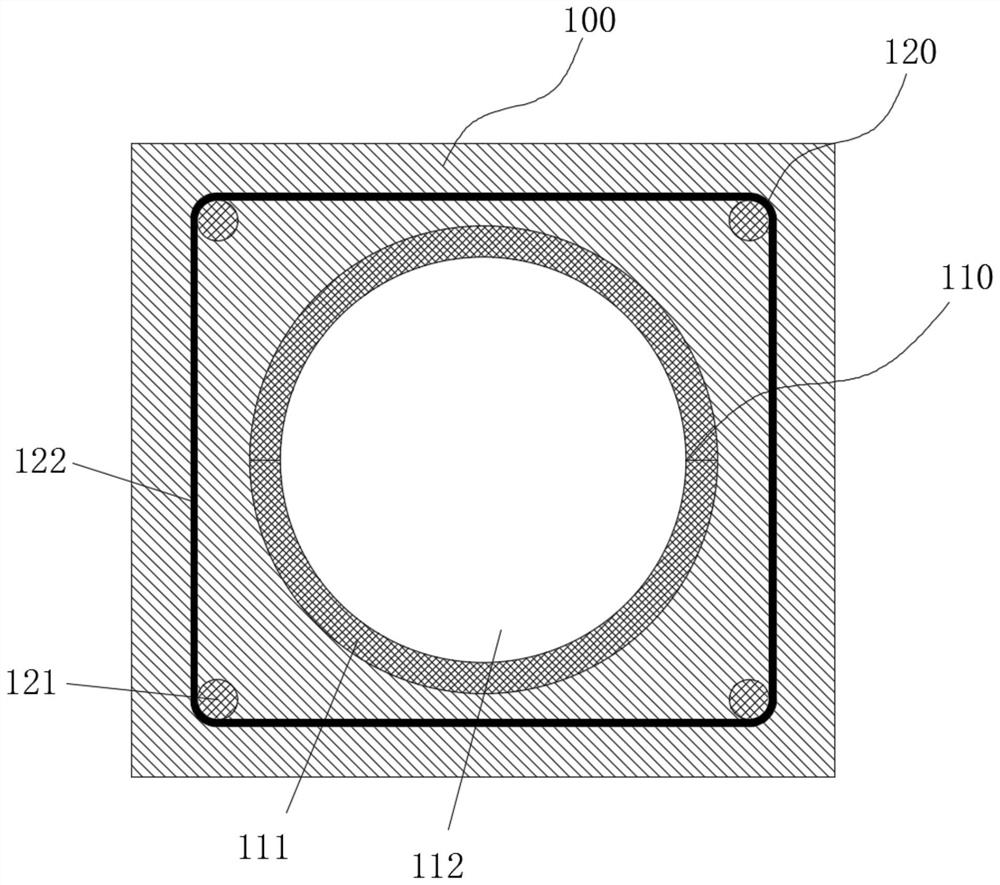

[0046] refer to figure 1 , the seal includes an annular rubber main body 100. The rubber main body 100 is equipped with an intermediate frame 110 for enhancing its compression and tear resistance. The rubber main body 100 is also equipped with a reinforcing assembly 120. The intermediate frame 110 and the reinforcing assembly 120 are distributed at intervals , the reinforcing component 120 is used to maintain the shape and integrity of the rubber body 100 and improve its resistance to cracking and crushing; it can improve the compression resistance and tear resistance of the seal, and can also maintain the rubber body 100 under complex conditions of use without deformation. , No cracking and no broken, improve the service life of seals.

[0047] The intermediate frame 110 is annular, and the cross-section of the intermediate frame 110 perpendicular to its annular surface is circular; the intermediate frame 110 with a circular cross-section has good compressive ability, can res...

Embodiment 3

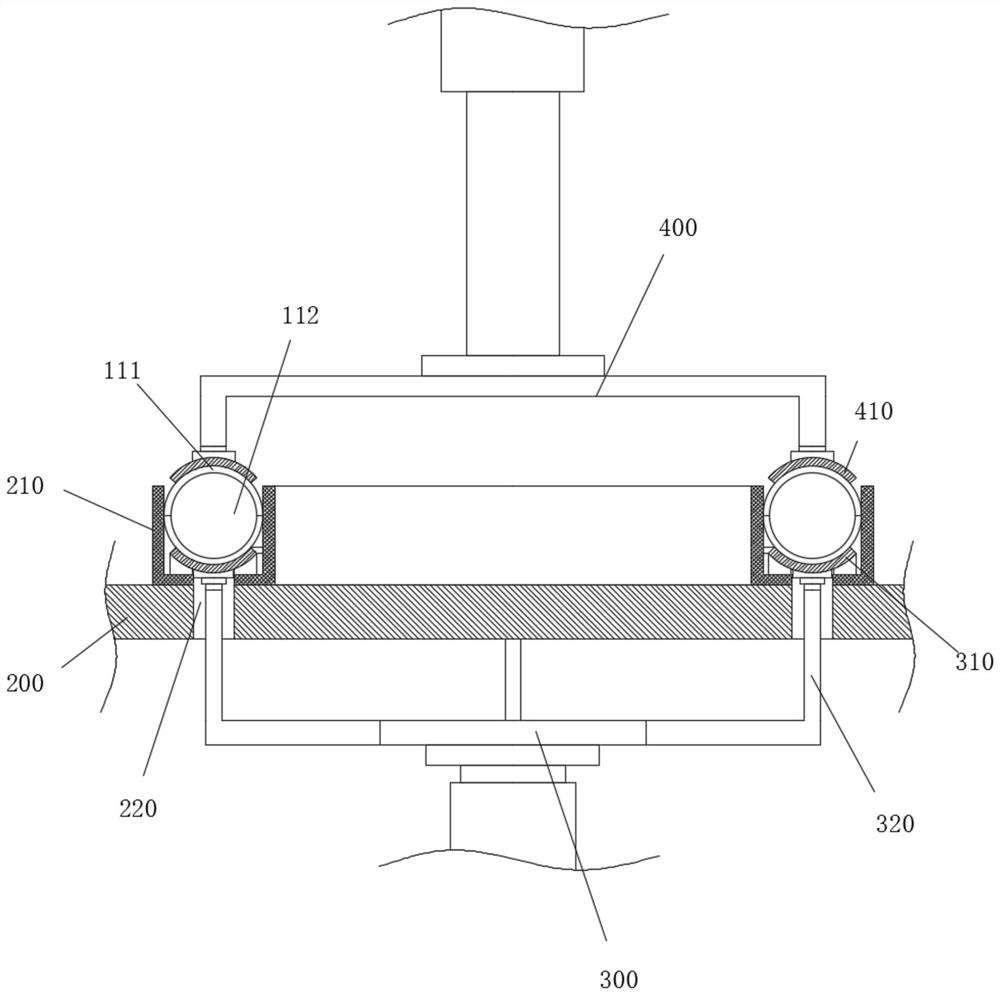

[0053] refer to figure 2 , in this embodiment, a pressing mechanism for the manufacture of wellhead seals for oil extraction machines is proposed, including a workbench 200, the workbench 200 is fixedly installed, and an annular pressing groove 210 is installed on the workbench 200, and the pressing A lower annular plate 310 is installed in the groove 210. The lower annular supporting plate 310 has a supporting groove for supporting the skeleton 111. The skeleton 111 is opened in the supporting groove and distributed horizontally. The lower annular supporting plate 310 is connected to the lifting mechanism 300. , the lifting mechanism 300 adjusts the lower annular supporting plate 310 to enter and exit the pressing groove 210, the upper annular pressing plate 410 is installed above the lower annular supporting plate 310, the upper annular pressing plate 410 is connected to the pressing mechanism 400, and the pressing mechanism 400 is used to drive the upper annular pressing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com