Steel ladle repairing material produced by using recycled waste corundum nozzle seating brick material and method for repairing steel ladle lining by using the same

A waste corundum seat and repair material technology, which is applied in the field of refractory materials, can solve problems such as poor bonding effect, poor repair effect, and poor thermal shock resistance, and achieve the effects of strong economy and practicability, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below through specific embodiments, so as to facilitate the understanding of those skilled in the art.

[0018] The main material of the repair material in this application is the residual waste corundum seat bricks used in the recycled steel mills, and the price is 1800 yuan / ton.

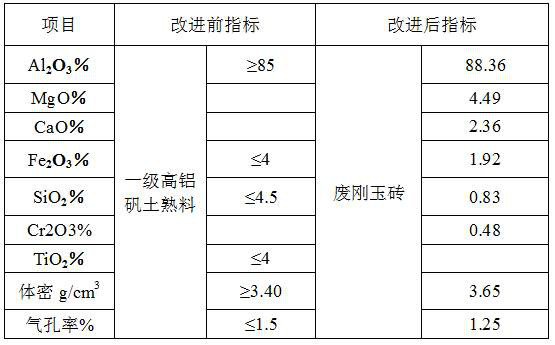

[0019] After sorting the recovered waste corundum seat bricks, they are crushed and processed into granules with different particle sizes (6-3mm, 3-1mm, 1-0mm), and some 1-0mm granules are passed through a magnetic separator to remove iron and magnetic substances. , and then processed into 200 mesh fine powder for subsequent use.

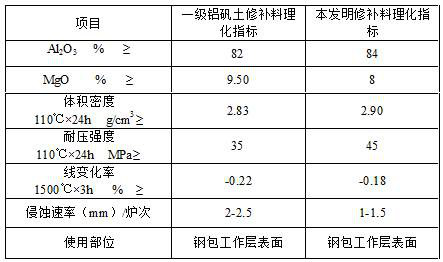

[0020] The ladle repair material of the present invention is prepared by using waste corundum bricks, spinel powder, fused magnesium powder, activated alumina micropowder, and 71 cement according to the following weight percentages:

[0021] 84% waste corundum brick material, including: 15% of particle size 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com