Up-conversion luminescence composite flexible transparent resin and preparation method and application thereof

A transparent resin, composite flexible technology, applied in the field of up-conversion luminescent composite flexible transparent resin and its preparation, can solve the problems of luminous efficiency limitation, affecting the application of flexible transparent resin, and sacrifice of light transmittance, so as to facilitate subsequent reprocessing, The effect of short cycle and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention discloses a preparation method of an up-conversion luminescent composite flexible transparent resin, comprising:

[0021] (1) Adding a ligand linker, a noble metal source and a reducing agent to the dispersion of up-conversion luminescent particles, an in-situ reduction reaction occurs to obtain up-conversion luminescent particles loaded with noble metals on the surface;

[0022] (2) Dispersing the up-conversion luminescent particles loaded with precious metals on the surface in a curing agent solution, adding a transparent resin solution and then heating and curing to obtain the up-conversion luminescent composite flexible transparent resin.

[0023] In some embodiments of the present invention, in step (1), the mass ratio of the up-conversion luminescent particles to the noble metal source is (1269 to 211):1, for example, it can be 211:1, 215:1, 220:1 , 230:1, 250:1, 280:1, 300:1, 400:1, 500:1, 600:1, 700:1, 800:1, 900:1, 1000:1, 1100:1, 1200 :1, 1269:1...

Embodiment 1

[0075] In a 20mL glass bottle, 25mg of NaGdF 4 : Yb, Er particles were dispersed into the aqueous solution, and 2mL of 2.4mM polyvinylpyrrolidone (molecular weight: 55000) was added as a ligand linker (at this time, the mass ratio of up-converting luminescent particles to them was 0.09:1), and then 20uL of 10mM chloroauric acid was added as Gold source, at room temperature, stirred for 15 minutes to fully contact the three, and finally added dilute concentration of 900uL 100mM ascorbic acid as a reducing agent (at this time, the mass ratio of up-conversion luminescent particles to its mass was 2:1), after 30 minutes of slow reduction process, gold nanoparticles It is directly loaded on the surface of the up-conversion luminescent particle, and its size is distributed in the range of 4-20nm.

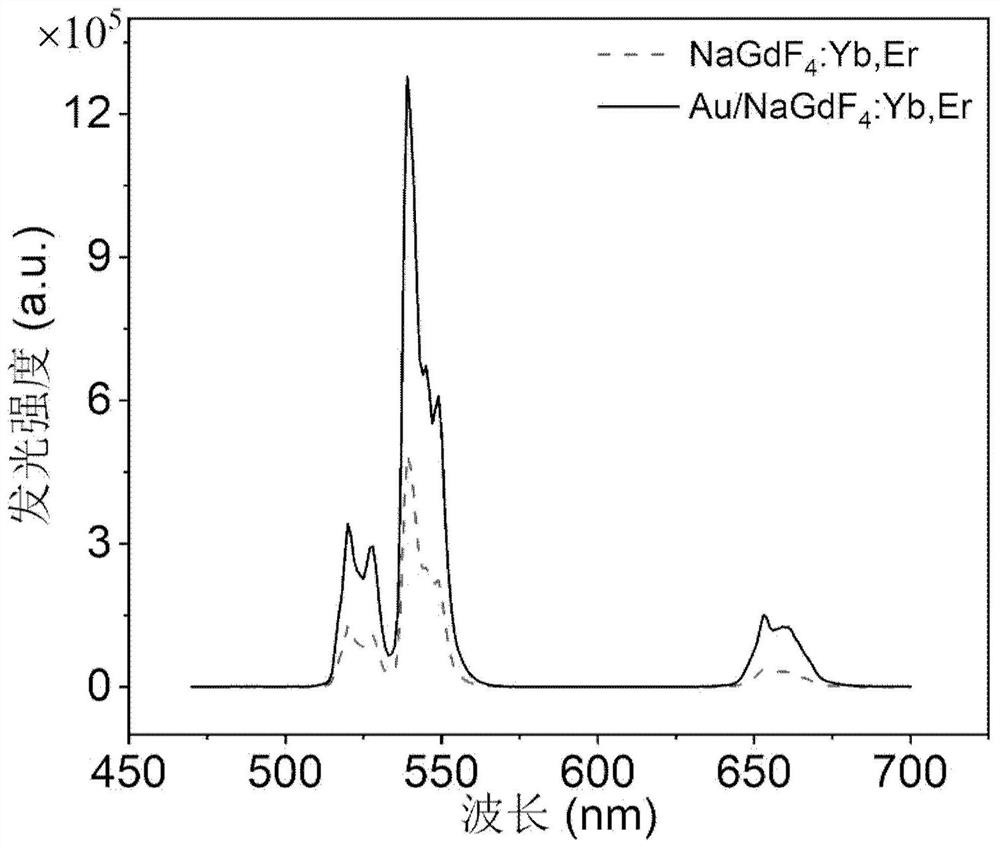

[0076] After the reaction, the sample powder before and after loading was taken to test the luminous intensity by a steady-state-transient luminescence spectrometer. The detection condit...

Embodiment 2

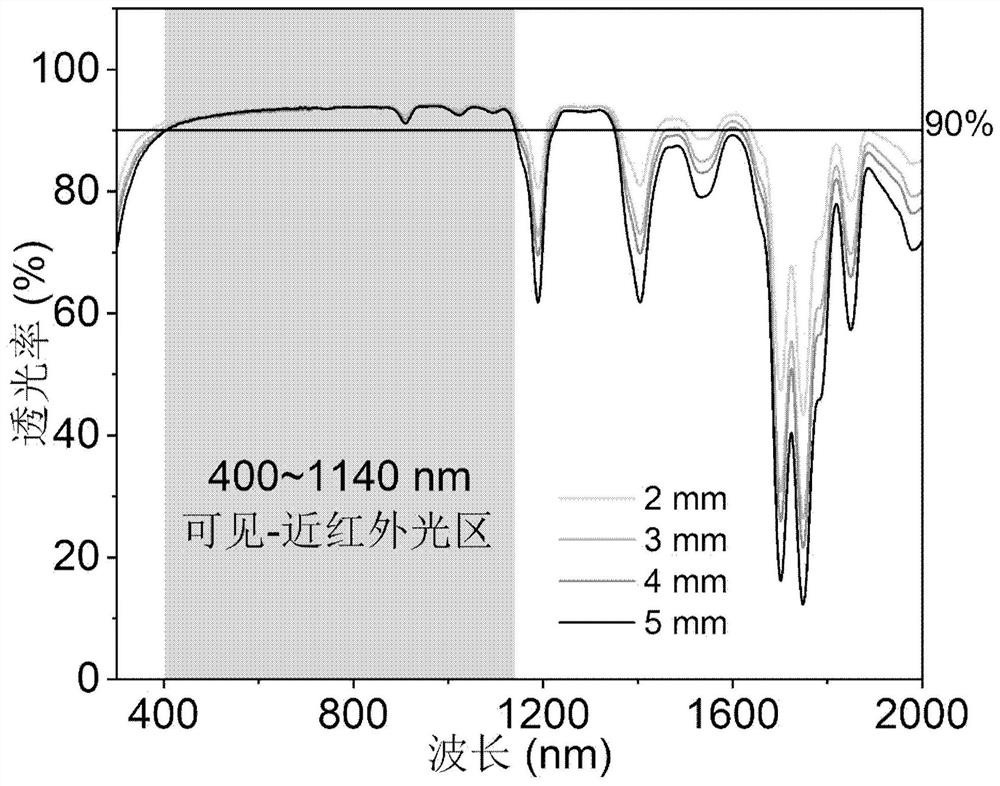

[0080]The specific reaction process and detection method are the same as in Example 1, except that after pouring part of the mixed flexible transparent resin liquid into a circular mold with a diameter of 3.5 cm, the thickness is 3 mm, and the light transmittance in the visible-near-infrared light region still reaches 90%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com