Sound-attenuation damping flame-retardant plane material and manufacturing method thereof

A production method and surface material technology, applied in the field of labels, can solve the problems of poor flame retardant performance and affect the use experience, and achieve the effects of good flame retardant effect, increased damping and shock absorption effects, and high shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

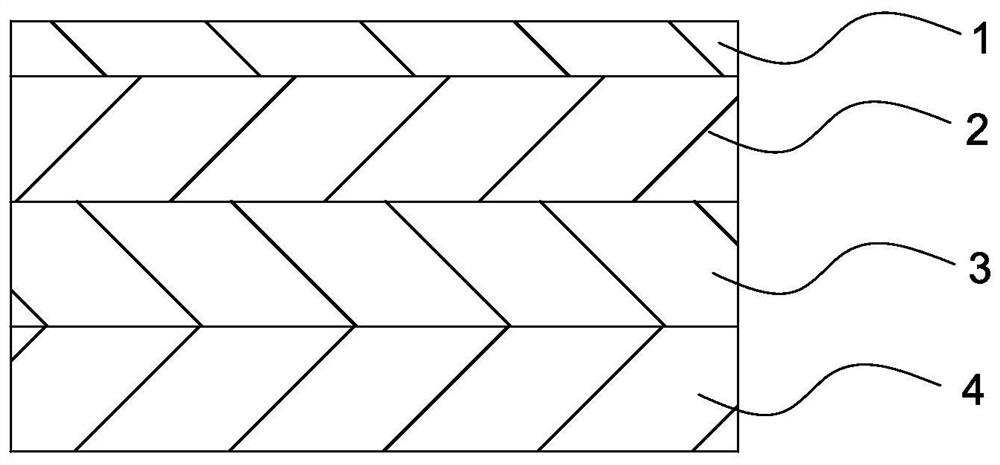

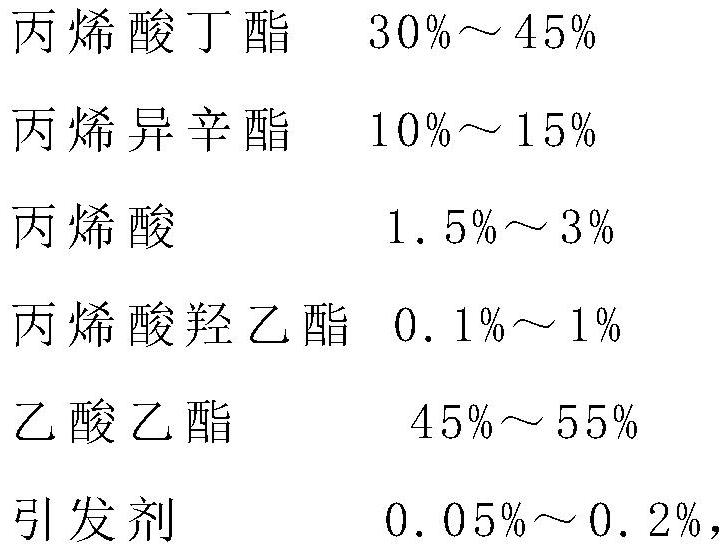

[0028] Embodiment one: see figure 1 As shown, a sound-absorbing, damping, and flame-retardant surface material includes a coating 1, a first surface material layer 2, a glue layer 3, and a second surface material layer 4 arranged sequentially from top to bottom. The first surface material layer is passed through The glue layer is bonded on the second surface material layer, the glue layer is glue, the first surface material layer and the second surface material layer are both made of PET, and the glue is composed of component A and Component B is mixed, the ratio of component A to component B is 1:0.8~1, and component A includes butyl acrylate, propylene isooctyl, acrylic acid, hydroxyethyl acrylate, ethyl acetate And initiator, the proportion of each composition is:

[0029]

[0030] The component A is a synthetic glue with a solid content of 35% to 50%;

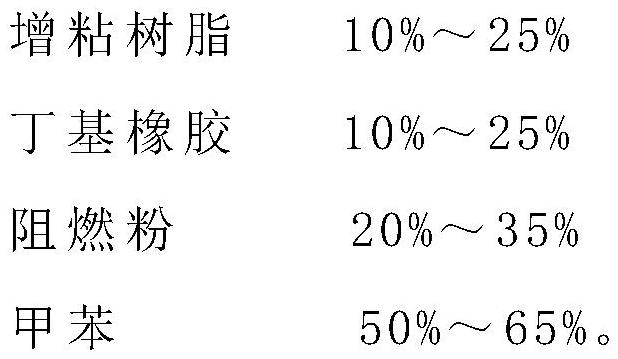

[0031] The component B includes tackifying resin, butyl rubber, flame retardant powder and toluene, and the proporti...

Embodiment 2

[0046] Example 2: Add 70 parts of butyl acrylate, 25 parts of propylene isooctyl, 4.5 parts of acrylic acid, 0.5 parts of hydroxyethyl acrylate, and 100 parts of ethyl acetate into the reaction device, introduce nitrogen and stir for half an hour, and slowly heat up to 80 ℃, add 0.2 parts of AIBN (azobisisobutyronitrile initiator), react for 8 hours under the protection of nitrogen, and finally use the internal ethyl acetate to adjust it to a synthetic glue with a solid content of 40% (component A);

[0047] Add 100 parts of the above synthetic glue (component A), add 15 parts of tackifying resin KF364, 10 parts of butyl rubber, 30 parts of flame retardant powder, 62.5 parts of toluene (component B), mix well, and then get the glue Coated on the 12 μm PET second surface material layer, coated with a glue layer thickness of 25 μm, and compounded the 12 μm PET first surface material layer on the glue layer.

Embodiment 3

[0048] Example Three: Add 70 parts of butyl acrylate, 25 parts of propylene isooctyl, 4.5 parts of acrylic acid, 0.5 parts of hydroxyethyl acrylate, and 100 parts of ethyl acetate into the reaction device, introduce nitrogen and stir for half an hour, and slowly heat up to 80 ℃, add 0.2 parts of AIBN (azobisisobutyronitrile initiator), react for 8 hours under the protection of nitrogen, and finally use the internal ethyl acetate to adjust it to a synthetic glue with a solid content of 40% (component A);

[0049] Add 100 parts of the above synthetic glue (component A), 10 parts of tackifying resin KF364, 15 parts of butyl rubber, 30 parts of flame retardant powder, 62.5 parts of toluene (component B), mix well, and then get the glue Coated on the 12 μm PET second surface material layer, coated with a glue layer thickness of 25 μm, and compounded the 12 μm PET first surface material layer on the glue layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com