Automatic flat plate coating machine

A coating machine and flat plate technology, applied in the field of biology, can solve problems such as uneven coating, easy pollution, and high requirements for experimental personnel's operating skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

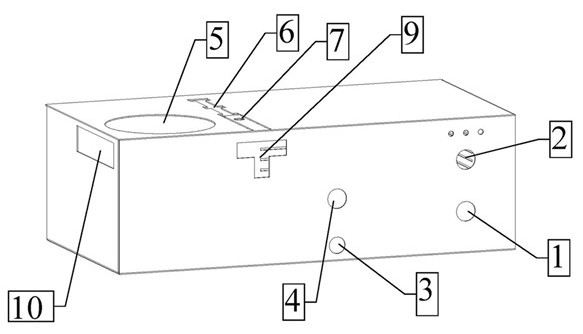

[0030] 1 Installation of the tablet

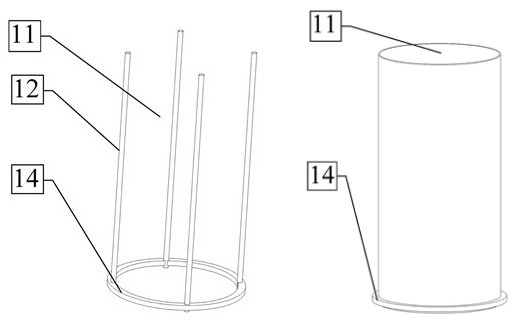

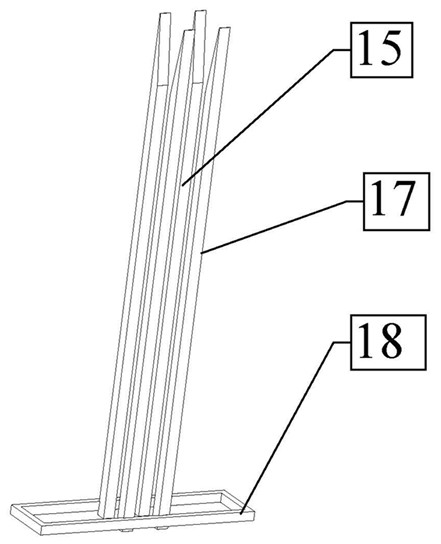

[0031] Put the well-packed flat plates (10 sets per bag) on the operating table, turn them upside down, with the cover facing down, and the medium side facing up. Pay attention to arrange them neatly to avoid dumping; cut the packaging bag along the sealing position, and hold it in your hand. Flat plate loading frame chassis (reference number 14), the flat plate loading frame is inserted in the packaging bag, and flat plate is loaded into flat plate and is contained in the cabin simultaneously. After inserting it to the bottom, place one finger in the middle of the bottom plate, and hold the packaging bag and the lower end of the loading compartment or the fixing rod (reference number 12) with the other hand, tilt at a certain angle, press the finger on the bottom plate, turn over the plate loading frame, and place it on the main machine (reference number 31). Push the plate loading frame into the main machine (reference number 31) plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com