A kind of hygroscopic antibacterial mask base cloth and preparation method thereof

A base fabric and mask technology, which is applied to non-woven fabrics, rayon made of viscose, textiles and papermaking, etc., can solve the problems of the base fabric having no antibacterial function and the general hygroscopicity of the mask base fabric. The effect of bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

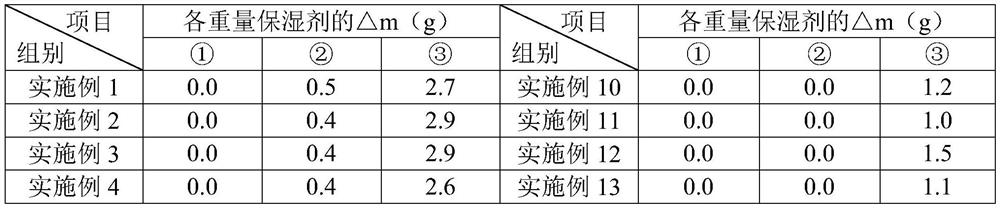

Examples

Embodiment 1

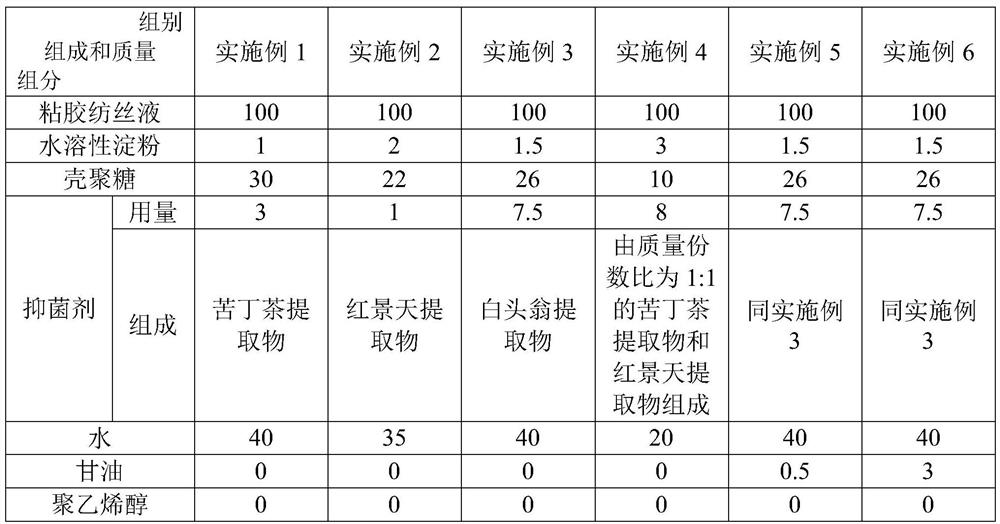

[0046] Example 1: A hygroscopic and bacteriostatic mask base fabric, obtained from spinning dope by spunlace reinforcement after wet spinning. The components, composition and quality of the spinning dope are shown in Table 1.1. Prepare in the following steps:

[0047] S1: Preparation of the spinning dope: put the raw materials of the spinning dope into the stirrer, and stir for 10 minutes at a temperature of 15°C and 50 r / min to obtain a spinning dope;

[0048] S2: wet spinning: the spinning dope is transported to the spinning machine for wet spinning, the spinning aperture is 0.075 mm, and the spinning speed is 50 m / min to obtain viscose fibers;

[0049] S3: Preparation of base fabric: the viscose fiber is opened and combed to form a fiber web, then cross-laid, the laid fiber web is spunlaced and reinforced, and dried under hot air at 80°C;

[0050] In the spunlace reinforcement, the first micro water flow is 30 bar, the hole spacing of the three-row water needle plate is 2....

Embodiment 2-6

[0051] Example 2-6: A hygroscopic antibacterial mask base cloth, the difference from Example 1 is that the components, composition and quality of the spinning dope are shown in Table 1.1.

Embodiment 7-8

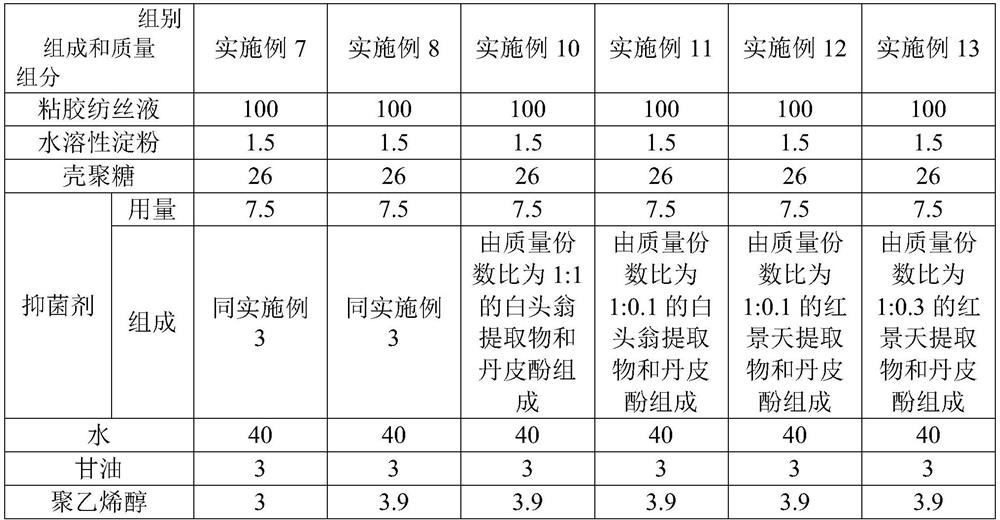

[0052] Example 7-8: A hygroscopic and antibacterial mask base cloth, the difference from Example 1 is that the components, composition and quality of the spinning dope are shown in Table 1.2.

[0053] Step S1: Preparation of spinning dope: put water and polyvinyl alcohol into the stirrer, stir for 10 minutes at 90°C and 60r / min, keep the stirring speed of 50r / min, cool down to 35°C, and then add the remaining raw materials , and the spinning stock solution was obtained after stirring for 10 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com