Corrugated steel underground chamber structure

A technology for underground chambers and corrugated steel, applied in underground chambers, shaft linings, tunnel linings, etc., can solve problems such as slow construction progress, poor mechanical performance, complex structure of underground chambers, etc., to speed up construction progress, The effect of fast construction speed and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

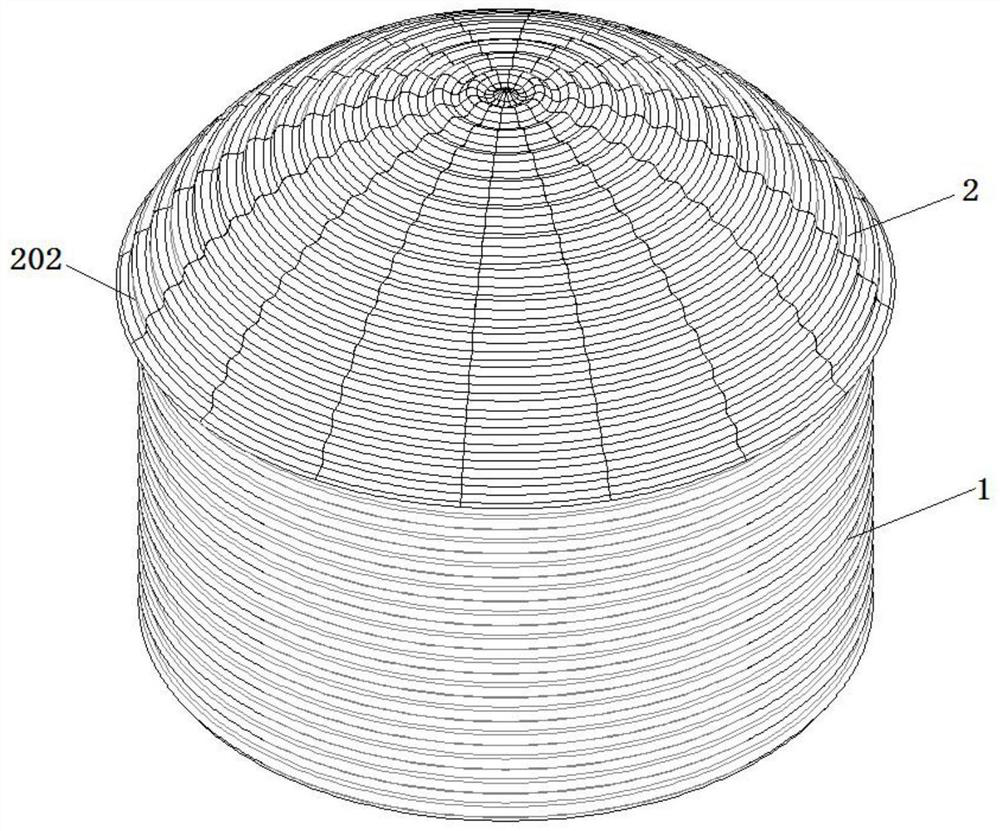

[0029] see figure 1 , a corrugated steel underground chamber structure, comprising a steel corrugated plate dome structure and a composite concrete support structure arranged outside the steel corrugated plate dome structure, the steel corrugated plate dome structure includes a tank body 1 and a ball arranged on the upper end of the tank body 1 The crown 2 and the tank body 1 are sequentially stacked and welded or bolted to form a barrel-shaped structure by multiple sets of ring-shaped steel corrugated plates. The lower end of the tank body 1 is provided with connectors, which are bolted or welded to the embedded parts of the inner cap of the surrounding rock (not shown in the figure). The corrugated plate 3 is spliced, and the lower end of the spherical cap 2 is bolted or welded to the upper end of the tank body 1;

[0030] see Figure 5 , the composite concrete support structure includes anchorage system 4 and concrete system 5, anchorage system 4 includes the anchor cable...

Embodiment 2

[0033] see figure 2 , different from Embodiment 1, in this embodiment, the spherical cap 2 is sequentially bolted or welded horizontally through multiple fan-shaped corrugated steel strips 202 to form an arched cover, and the fan-shaped corrugated steel strips 202 are made of several steel corrugated plates 3. Bolted or welded horizontally or vertically in turn.

Embodiment 3

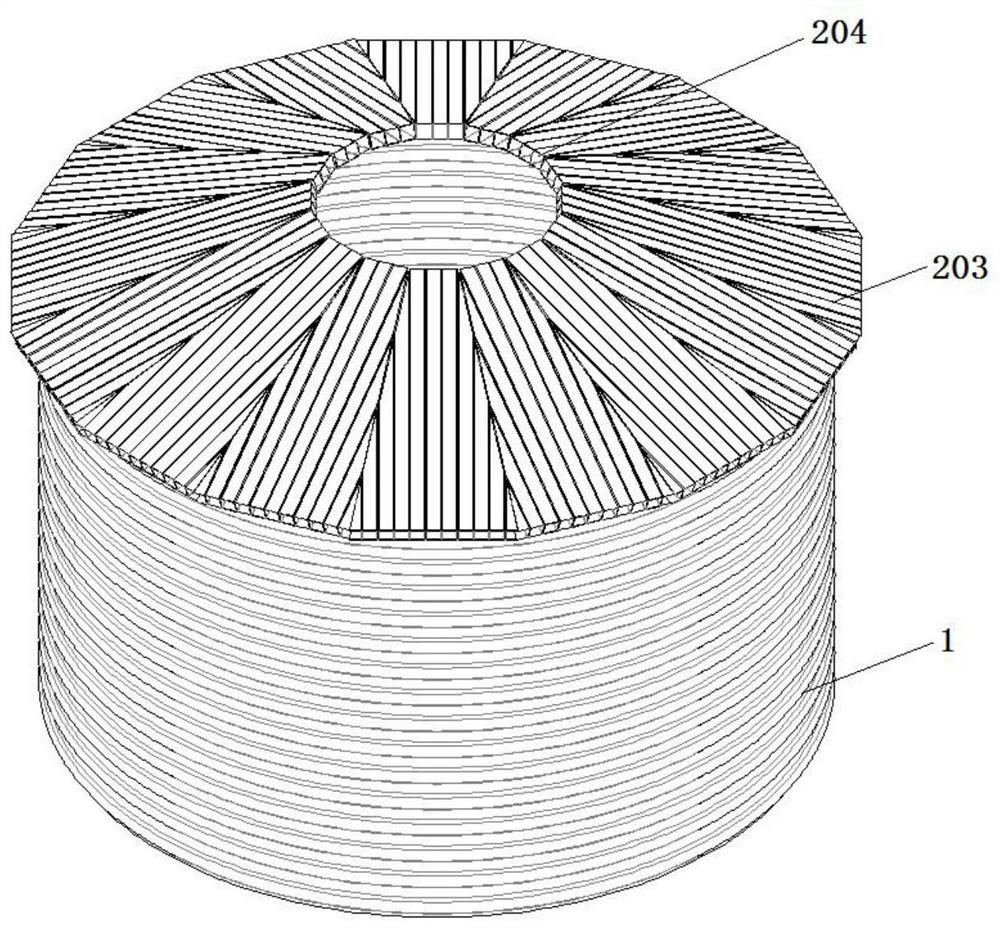

[0035] see image 3 , different from Embodiment 1, the spherical crown 2 includes an outer ring crown 203, a center frame 204 and an inner crown (not shown in the figure), and the center frame 204 is a regular hexagonal hollow frame structure, and the hollow frame is filled with In self-compacting concrete, each side of the center frame 204 is bolted or welded with a piece of fan ring corrugated steel belt 202, and multiple fan ring corrugated steel belts 202 are sequentially bolted or welded to form an outer ring crown 203, and the fan ring corrugated steel belt 202 is composed of A number of corrugated steel plates 3 of different lengths are bolted or welded in turn horizontally or vertically. The inner crown is welded on the upper part of the center frame, and the inner crown is an arched small cover formed by connecting several steel corrugated plates.

[0036] In this embodiment, the central frame 204 is a regular hexagonal hollow frame structure. In other embodiments, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com