Transmission mechanism for realizing reciprocating motion

A technology of reciprocating motion and transmission mechanism, which is applied in transmission devices, friction transmission devices, machines/engines, etc. It can solve the problems of large and complex crank, connecting rod and crankshaft structures, reduced energy utilization, and increased transmission energy loss, so as to achieve convenient The effect of processing and assembly, reducing volume and weight, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

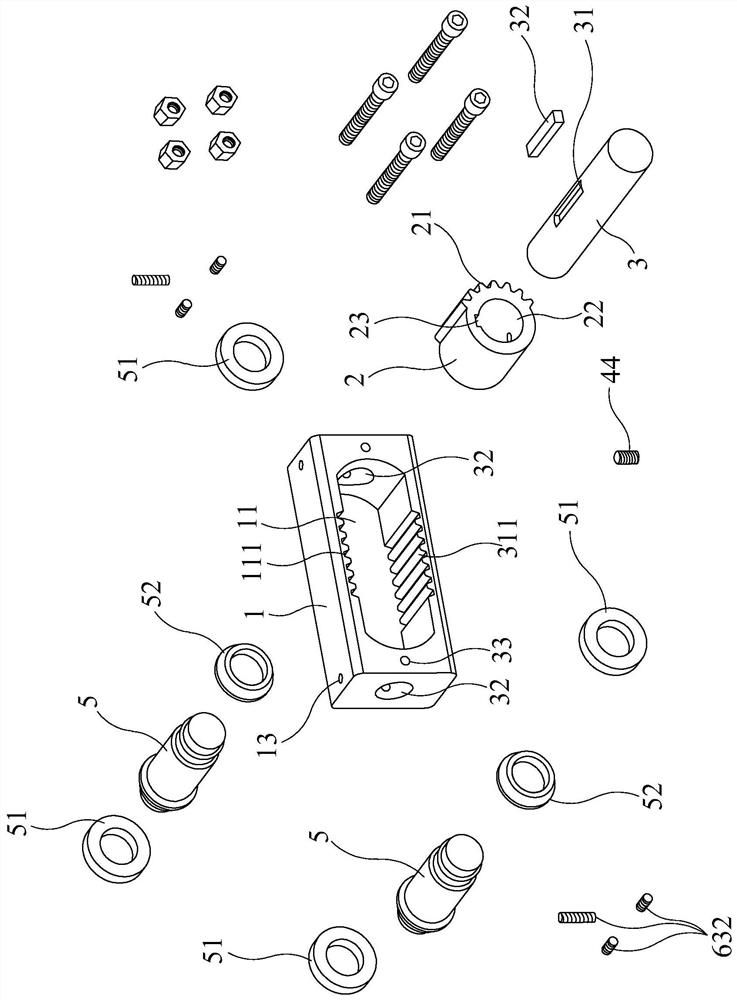

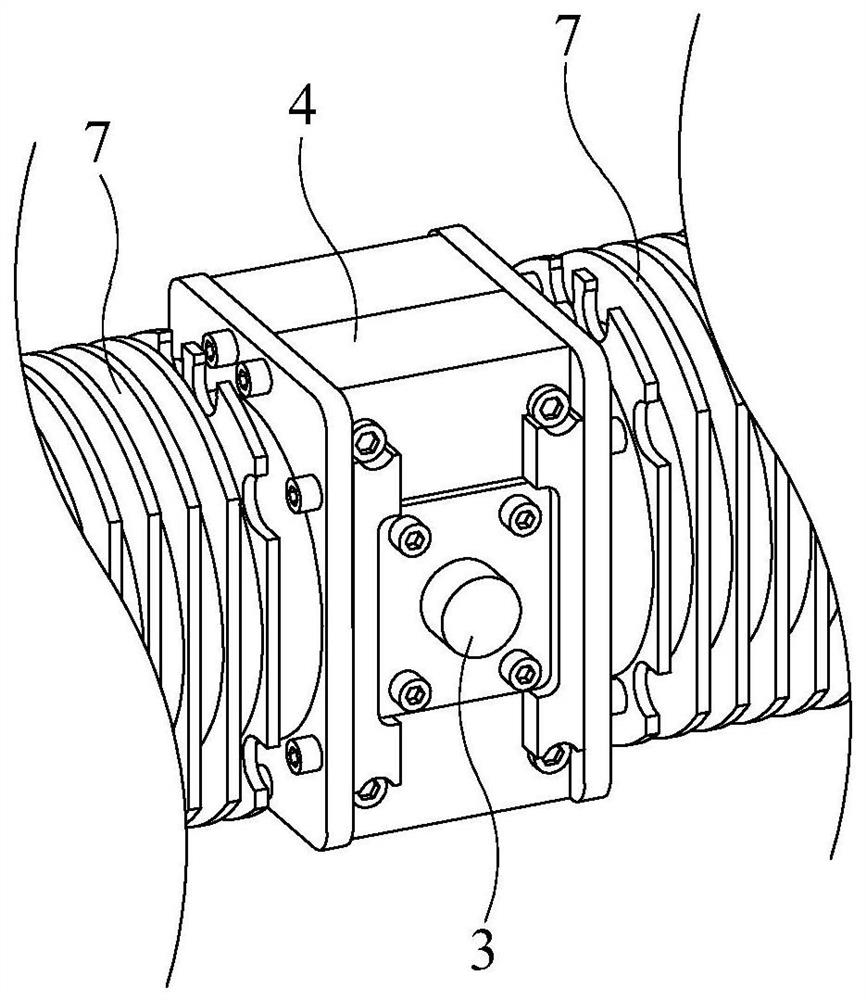

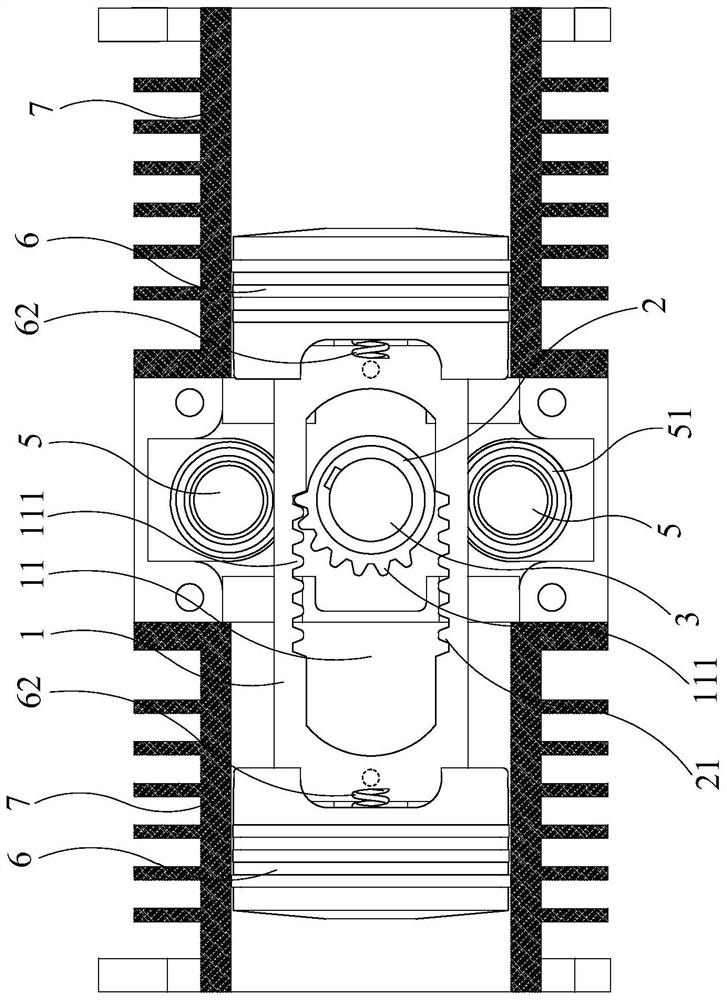

[0023] combine Figure 1 to Figure 6 As shown, the present invention discloses a transmission mechanism for realizing reciprocating motion. The transmission mechanism includes a long hole 11 formed in the push block 1. The push block 1 can be a rectangular body, and the long hole 11 can be A rectangle, the upper and lower walls of the elongated hole 11 form parallel surfaces, and the left and right side walls can form arc-shaped surfaces that expand outward to both sides. A section of hobbing surface 111 is respectively formed on the upper and lower walls of the elongated hole 11 , and the hobbing surface 111 can form a nearly wavy tooth surface. A rotatable running wheel 2 is provided in the elongated hole 11, so that the running wheel 2 forms a cylindrical body whose length matches the width of the hobbing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com