Multi-channel and multi-flow heat exchanger in mine fresh air heating system

A fresh air channel and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of complexity, high investment and operation costs, etc., to achieve increased flow rate, small construction amount, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

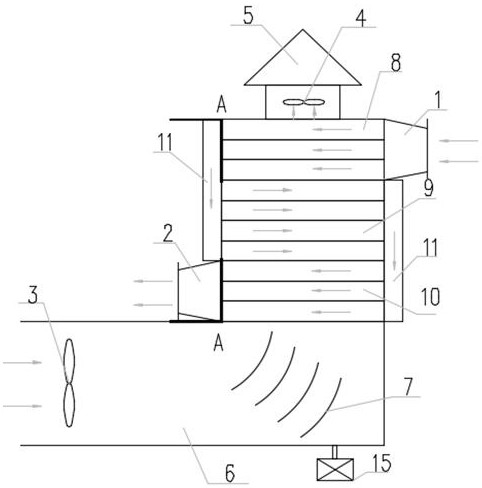

[0057] In this embodiment, the multi-channel and multi-process heat exchanger is applied to a mine to prevent freezing of the well head. Specifically, cancel the original diffusion tower at the air return port of the mine, and instead install the multi-channel and multi-process heat exchanger of the present invention, connect its return air inlet with the mine air outlet, and use the return air heat to cool the mine The fresh air is heated, and the heated fresh air flows out of the heat exchanger through the fresh air outlet 2 and enters the mine fresh air system to supply fresh air for the mine.

[0058] In order to make the return air entering the heat exchanger uniform, guide vanes 7 are arranged in the bend of the mine return air passage 6 .

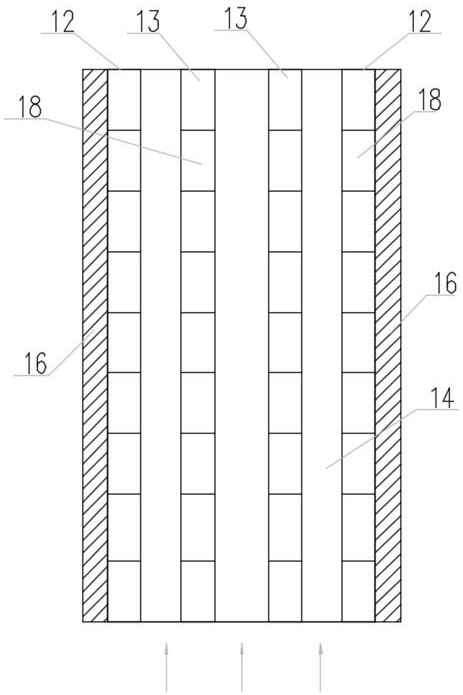

[0059] In the present embodiment, the flat tube 18 has a width of 150mm-400mm, a height of 100-250mm, and a wall thickness of 3-5mm. The material is carbon steel, stainless steel and other metal materials. The surface of the flat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com